A horizontal wiring cabinet

A wiring cabinet and horizontal technology, which is applied in the field of electrical quality inspection, can solve the problems of inconvenient drawing reference, inconvenient use of tools, and inconvenient inspection and detection, so as to change the wiring and detection process, improve the detection coverage, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

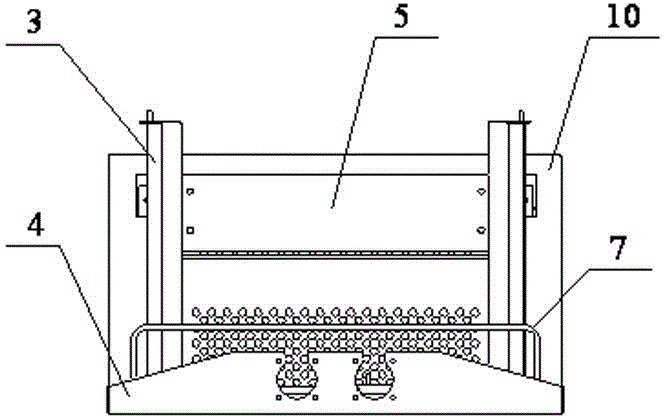

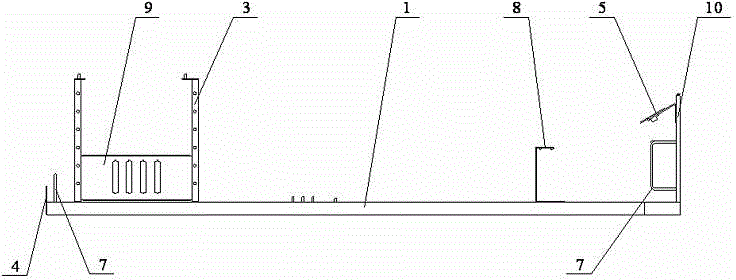

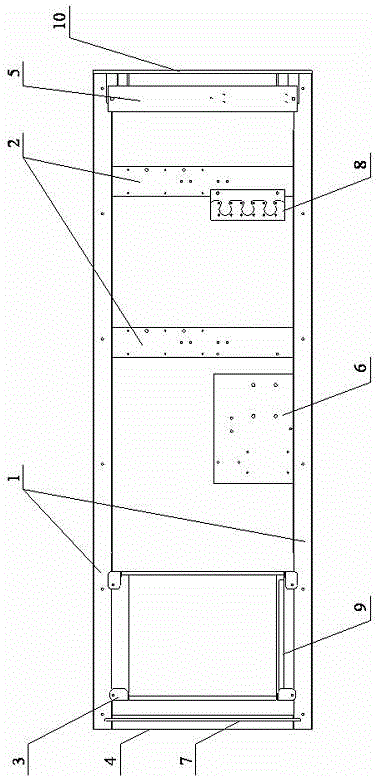

[0019] As a preferred embodiment of the present invention, the horizontal wiring cabinet also includes several binding rods 4 for binding test harnesses, such as Figure 1-3 shown. The position of the binding rod 4 can be selected according to the fixed position of the test wire harness. For example, if figure 1 Or as shown in 2, a tie rod 4 can be set near the plug fixing plate 4, and at the same time, a plurality of tie rods 4 can also be set on the bottom plate 10 of the wiring cabinet, such as figure 2 shown, but not limited to. It should be noted that the setting of the binding rod 4 cannot hinder the normal wiring operation, and it is also convenient for disassembly.

[0020] Such as figure 1 or image 3 As shown, a wiring harness fixing plate 2 close to the bottom plate 10 of the wiring cabinet is also provided with a test terminal adapter plate 8 . The test terminal adapter plate 8 is used for connecting and fixing external test plugs. Therefore, by assembling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com