Document transporter

A conveyor and document technology, applied in the directions of transportation and packaging, object supply, positioning objects, etc., can solve the problems of inability to reduce manufacturing costs, unfavorable assembly components, etc., and achieve the effect of structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will combine these drawings Figures 1 to 16 An embodiment of the document feeder according to the present invention will be described. The word "document" as used herein means a note, banknote, coupon, bond, tender, currency equivalent or any paper of value.

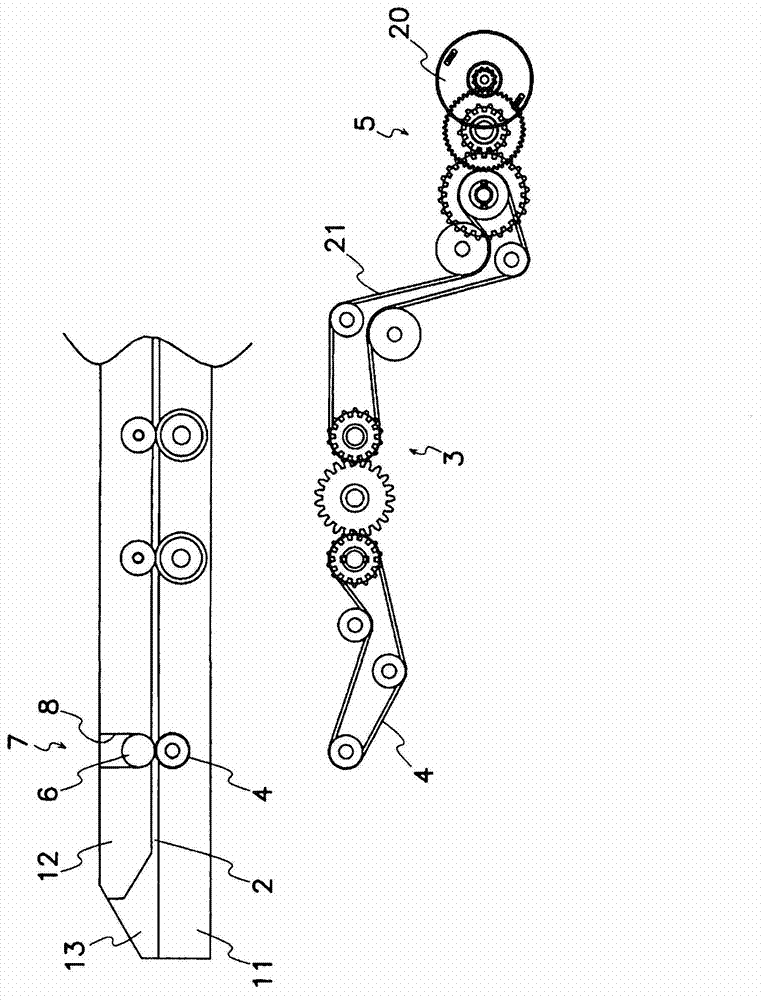

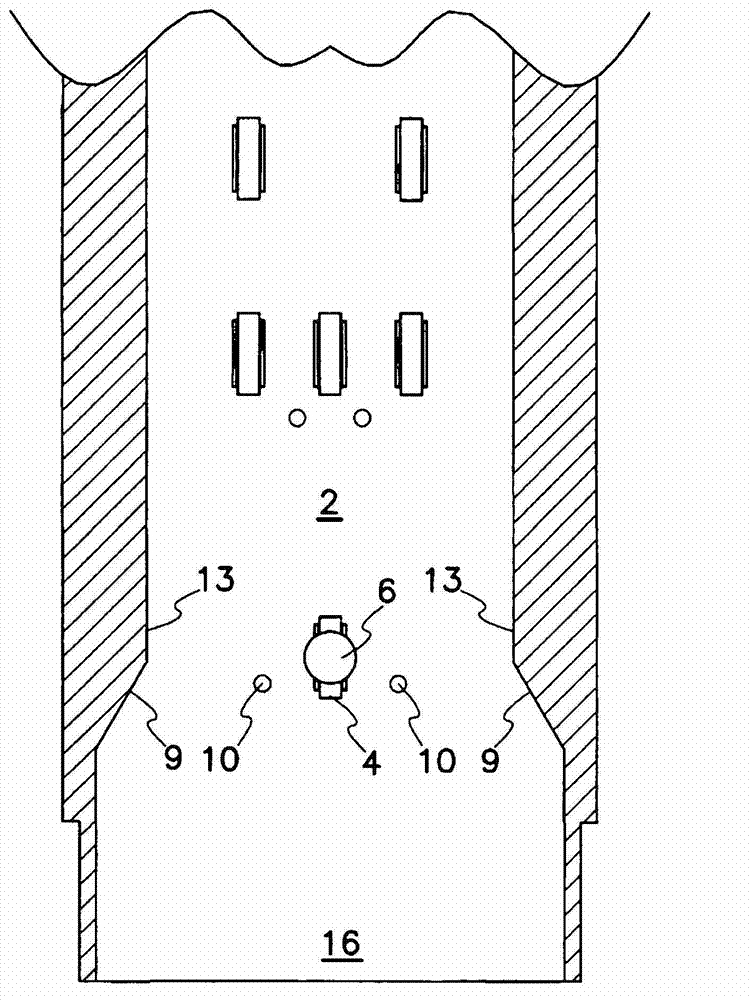

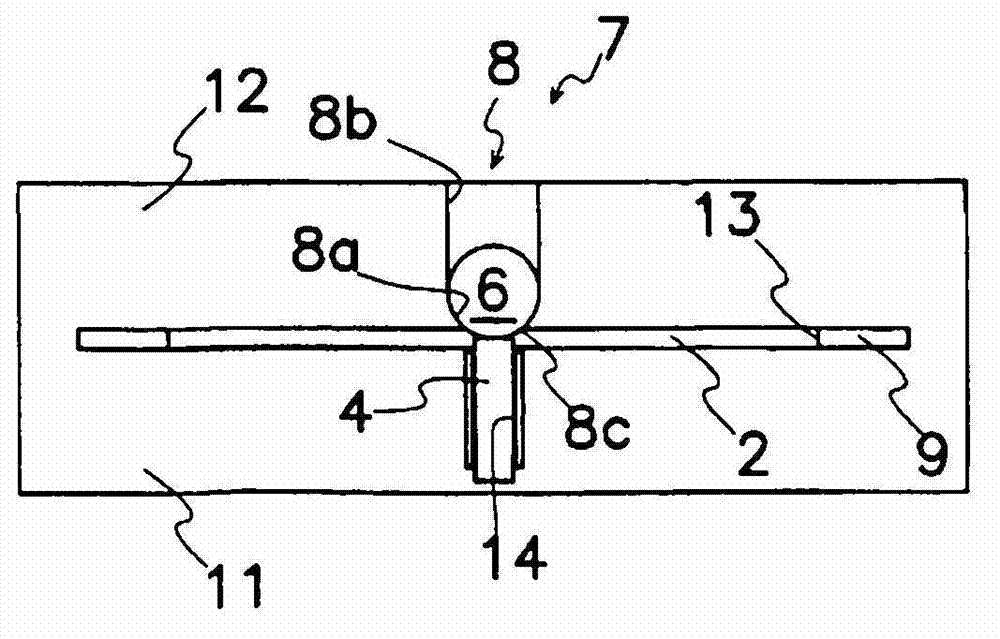

[0035] Figures 1 to 7 A first embodiment of the note feeder according to the invention is shown. Such as figure 1As shown, the note feeder comprises a lane 2 and a conveyor 3 for feeding notes 1 inserted into the lane 2 as documents. The channel 2 comprises a bottom wall 11, a top wall 12 and side walls 13, all formed of plastic or metal material. The conveyor 3 comprises a friction bearing 4 rotatably mounted in the channel 2, a drive device 5 for driving the friction bearing 4 and means for pushing or pressing the note 1 against the conveyor belt of the friction bearing 4. Heavy device7. Although the shown embodiment exemplifies the use of a friction carrier 4 using a conveyor belt, it coul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com