Reactor box chamber cleaning using molecular fluorine

A technology of reaction chamber and molecular fluorine, applied in the field of cleaning reaction chamber, can solve the problems of low efficiency of cleaning chamber and low quality efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention uses molecular fluorine for reaction chamber cleaning. In the present invention, it is shown that fluorine radicals generated by separating molecular fluorine are very efficient cleaning gases. The separation energy required for molecular fluorine is relatively low and can be provided by the RF power source already provided in the reaction chamber, ie the RF power source used to separate the deposition precursors. No remote plasma activation is required, so no additional equipment is required.

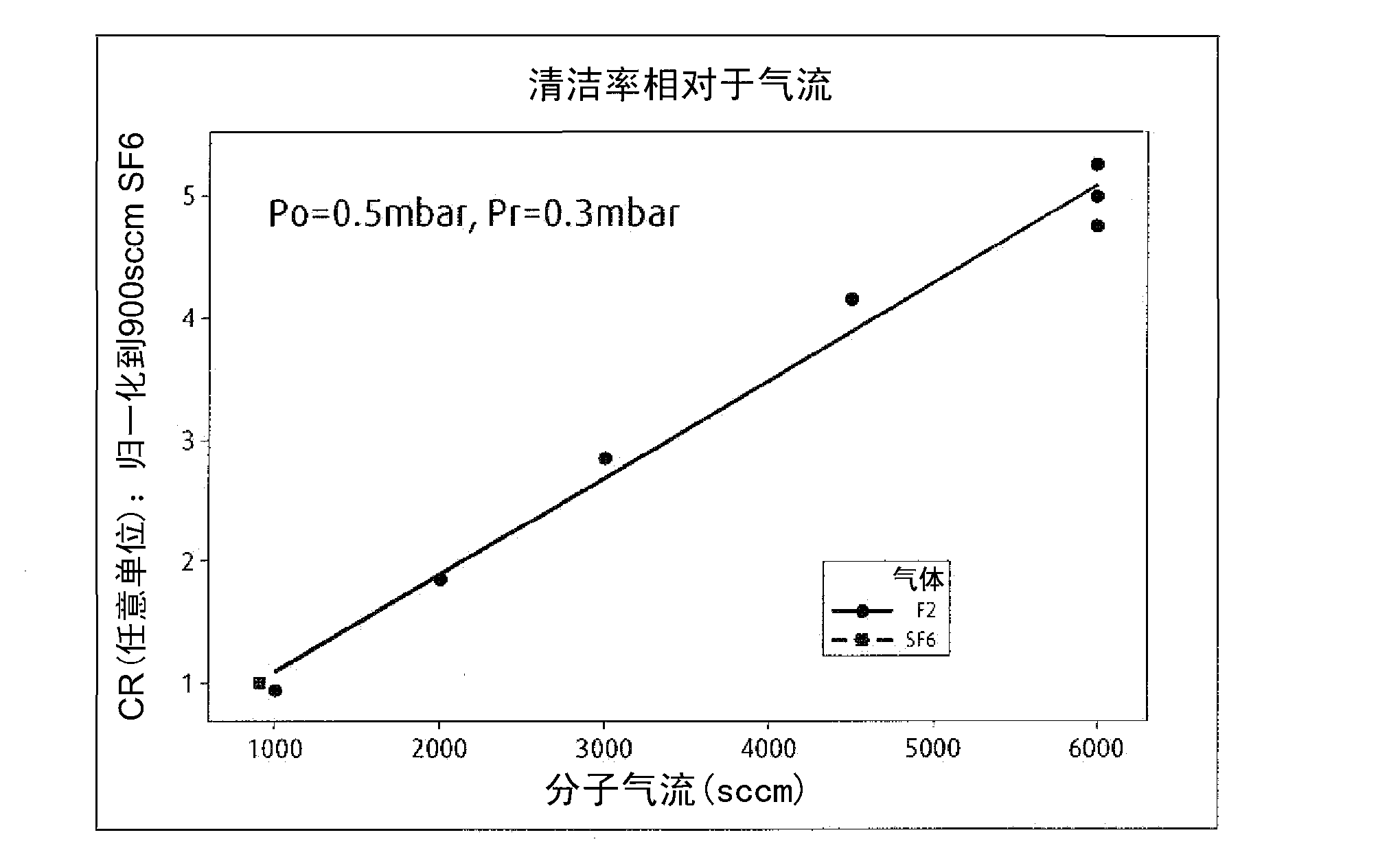

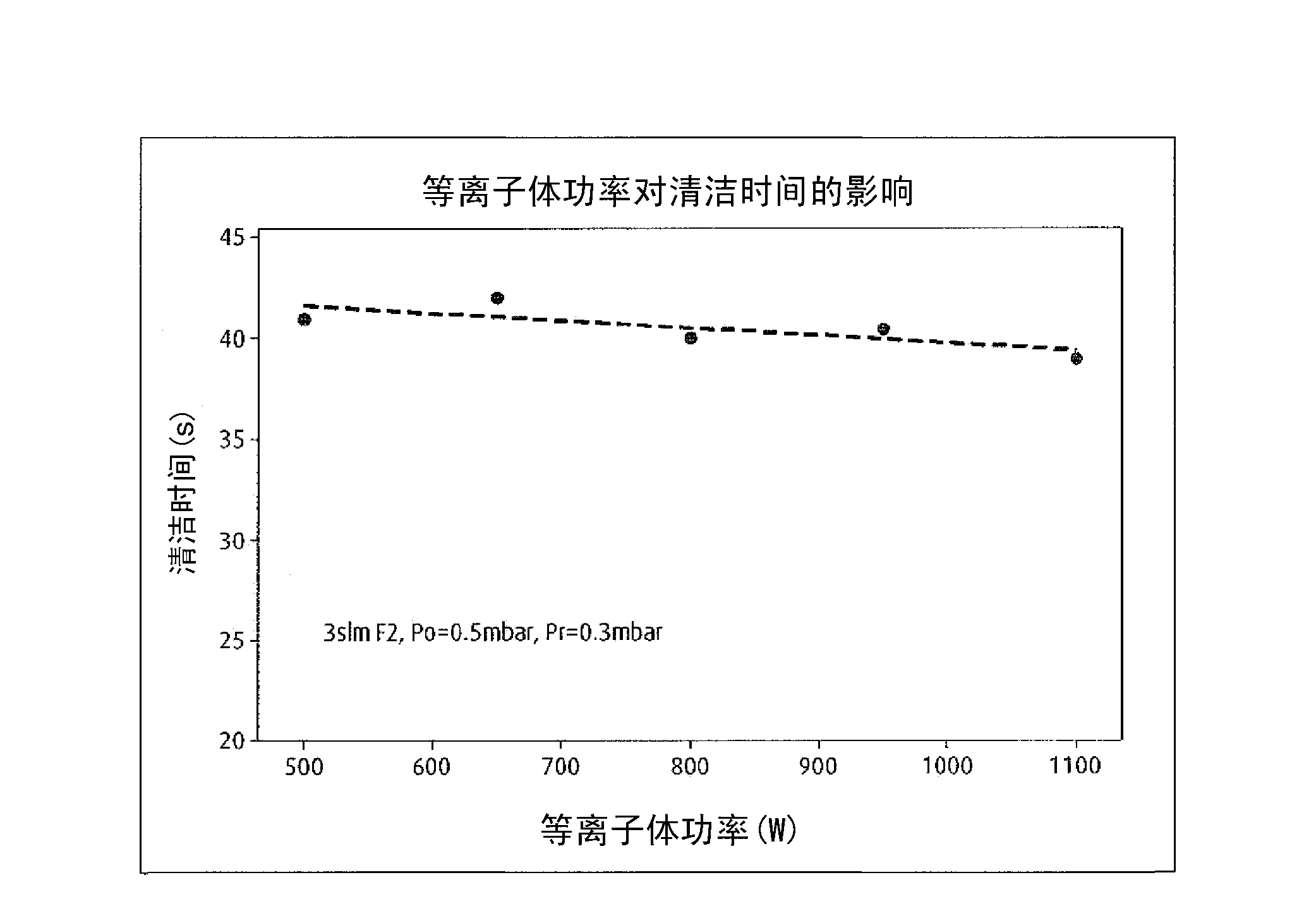

[0014] figure 1 is for molecular fluorine and SF 6 Graphs of both showing the effect on the cleaning rate of the reaction chamber based on the cleaning gas flow rate. in particular, figure 1 It was shown that molecular fluorine will efficiently clean chambers based on the concept of a reactor enclosed in a vacuum chamber, such as a reaction chamber or a plasma chamber, such as is commercially available from Oerlikon. In these types of chambers, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com