Superfine grinder with slag remover

A technology of ultra-fine pulverizers and crushing chambers, applied in grain processing, etc., can solve the problems of limited service life, great difference between usage and unit energy consumption, and inconvenient maintenance, so as to reduce equipment energy consumption, long service life, and easy maintenance convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

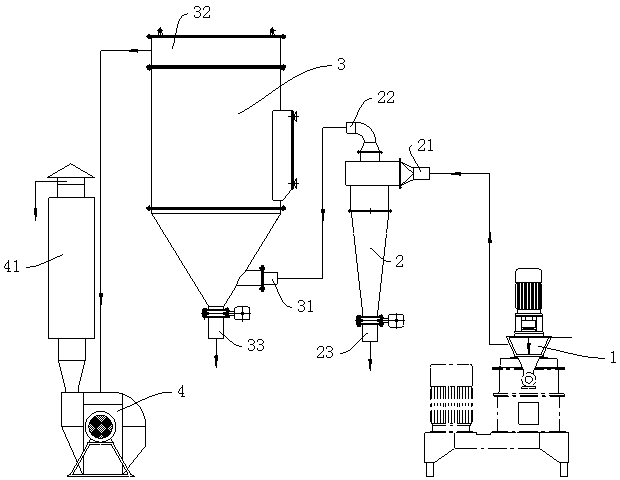

[0018] see figure 1 The micropowder preparation device shown includes an ultrafine pulverizer 1 , a cyclone dust collector 2 , a bag dust collector 3 , and an induced draft fan 4 .

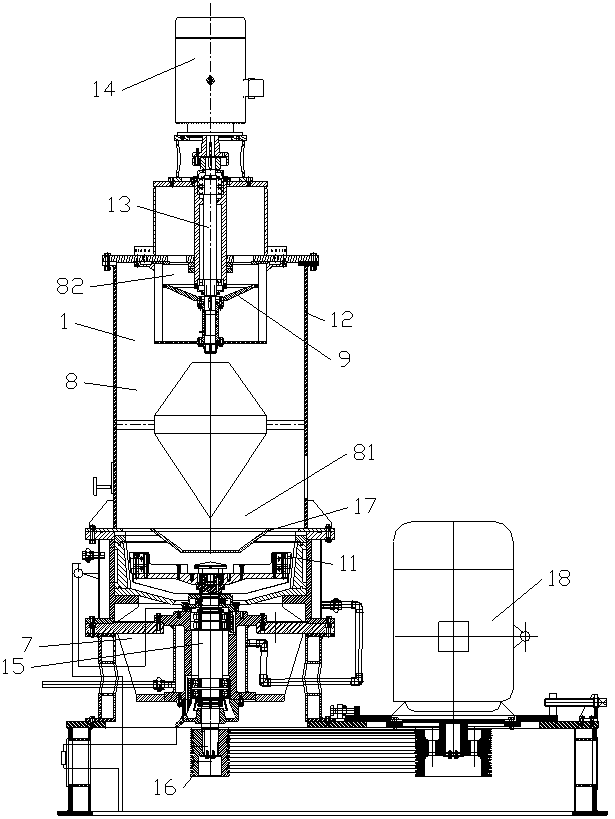

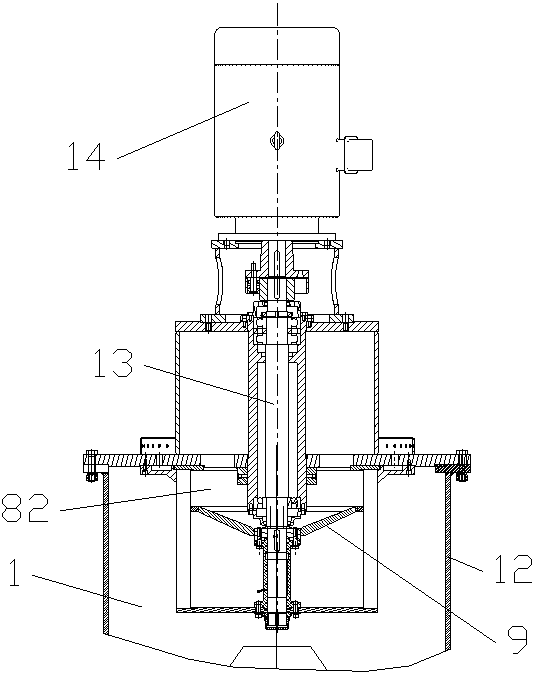

[0019] see figure 2 The shown ultrafine pulverizer 1 includes a casing 12, a feeding pipe 5 connected to the casing for sending pre-crushed materials into the crushing chamber, a discharge port 6, and an air inlet chamber 7 with a lower part in the casing. , The crushing and grading chamber 8 in the upper part.

[0020] The crushing and classifying chamber 8 includes a crushing chamber 81 and a classifying chamber 82 . A classifying impeller 9 is arranged in the crushing and classifying chamber 8 . The upper part of the classifying impeller is a classifying chamber 82, and the lower part is a crushing chamber 81. A crushing disc 10 is arranged in the crushing chamber....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com