Method for processing thin-wall semi-circular parts

A technology for semicircular parts and parts, which is applied in the field of processing thin-walled semicircular parts and parts. It can solve the problems of clamping deformation, poor rigidity of thin-walled parts, lack of positioning and orientation benchmarks, etc., so as to improve processing efficiency and reduce Investment cost, the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention provides a method for processing thin-walled semicircular parts. The method for processing thin-walled semicircular parts comprises the following steps:

[0032] 1) Prepare tube or bar;

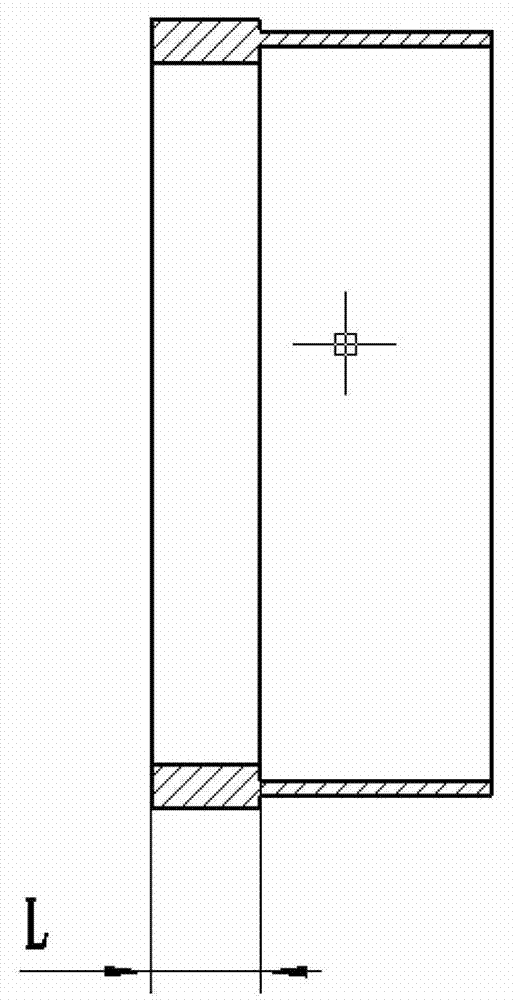

[0033] 2) Set up a process extension at either end of the tube or bar;

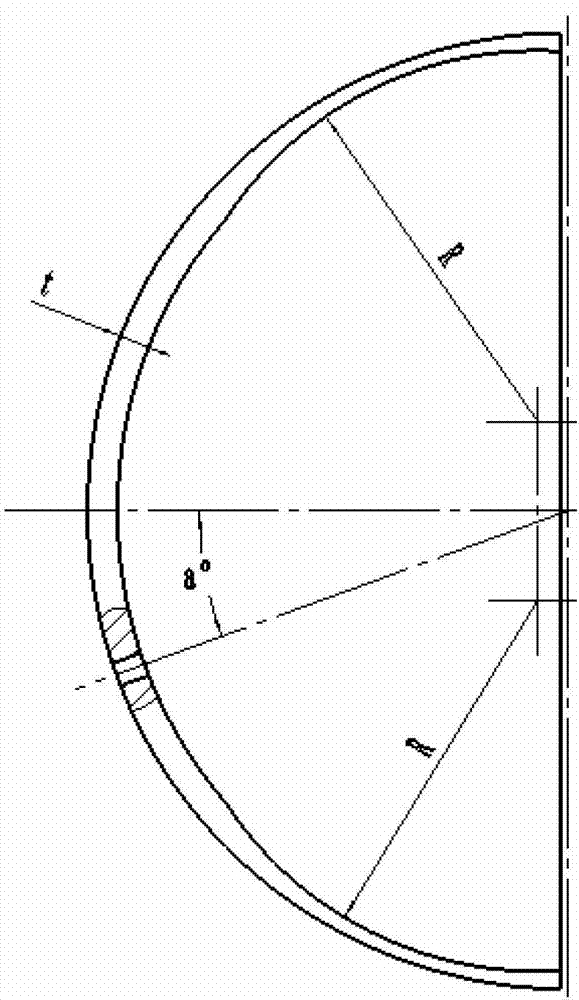

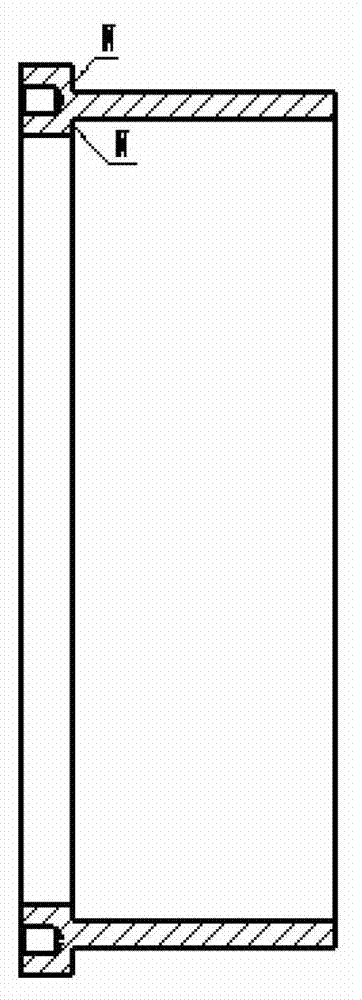

[0034] 3) Set reference holes on the end face of the process extension; the reference holes are arranged in pairs symmetrically along the center of the tube or bar; and the angular position between each pair of reference holes is related to the position of the shape element of the part . For example figure 1 , radial small hole, , the hole and the R arc surface have an angle requirement of а°, when the paired reference holes are set at the extended end, as shown in Figure 3, the angle between BB' and AA' and the fixture between CC' and AA' Both are а°, a single part has only one radial hole, the full circle processing is two radial holes, straighten the vertical direction of the positioning pin on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com