Quick cutter mounting mechanism

A tool-mounted and fast technology, applied in metal processing and other directions, can solve the problems of low degree of automation, restricted production capacity development, and dependence on installers, and achieves the effect of large installation space, reduced technology dependence, and rapid production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

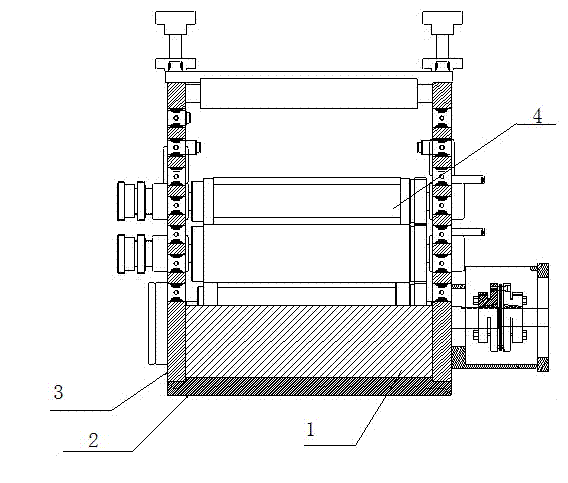

[0015] Such as figure 1 A fast tool loading mechanism is shown, the mechanism includes a limit plate 1, a workstation plate 3 is arranged on both sides of the limit plate 1, a knife 4 is arranged on the corresponding workstation plate, and a positioning plate is arranged at the bottom of the limit plate 1. The bottom plate 2 has a large installation space, which is more conducive to the fast and accurate installation of the installers, and reduces the technical dependence on the assemblers.

[0016] The above description is only a preferred embodiment of the present invention, and does not limit the present invention in any form. Although the present invention has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com