Silver nanoparticle-modified zinc oxide nanorod array and preparation method and application thereof

A technology of zinc oxide nanorods and silver nanoparticles, which is applied in the process of producing decorative surface effects, decorative art, gaseous chemical plating, etc., can solve the problem of not being able to prepare surface-enhanced Raman scattering active products, silver nanoparticles Easy, impossible to do and other problems, to achieve the effect of eliminating oxidation of silver nanoparticles, scientific preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

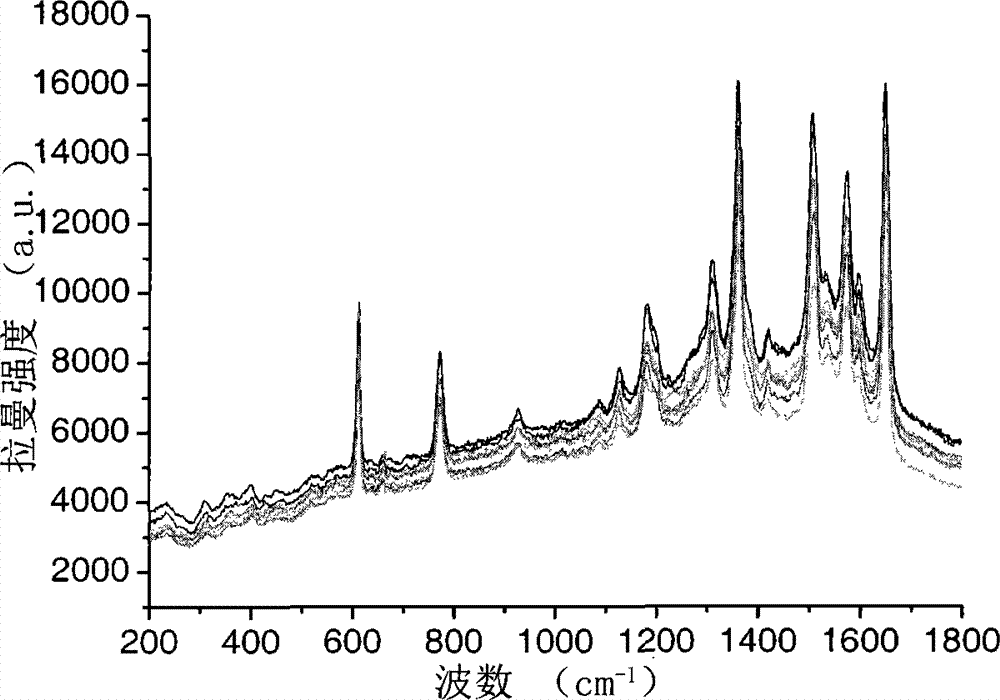

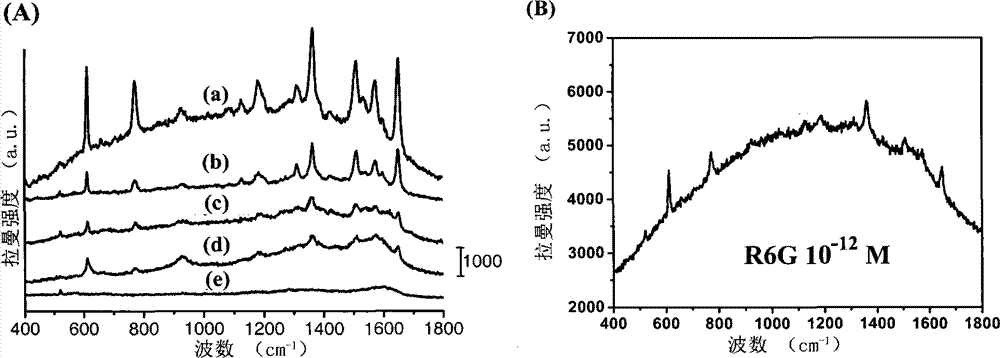

Embodiment 1

[0030] The specific steps of preparation are:

[0031] Step 1, firstly coat a zinc acetate ethanol solution with a concentration of 10 mmol / L on the substrate, and wash and disperse it with ethanol after drying; where the substrate is a silicon wafer. Then, the substrate with zinc acetate placed on it was thermally decomposed at 300° C. for 24 minutes to obtain a substrate covered with a zinc oxide seed layer.

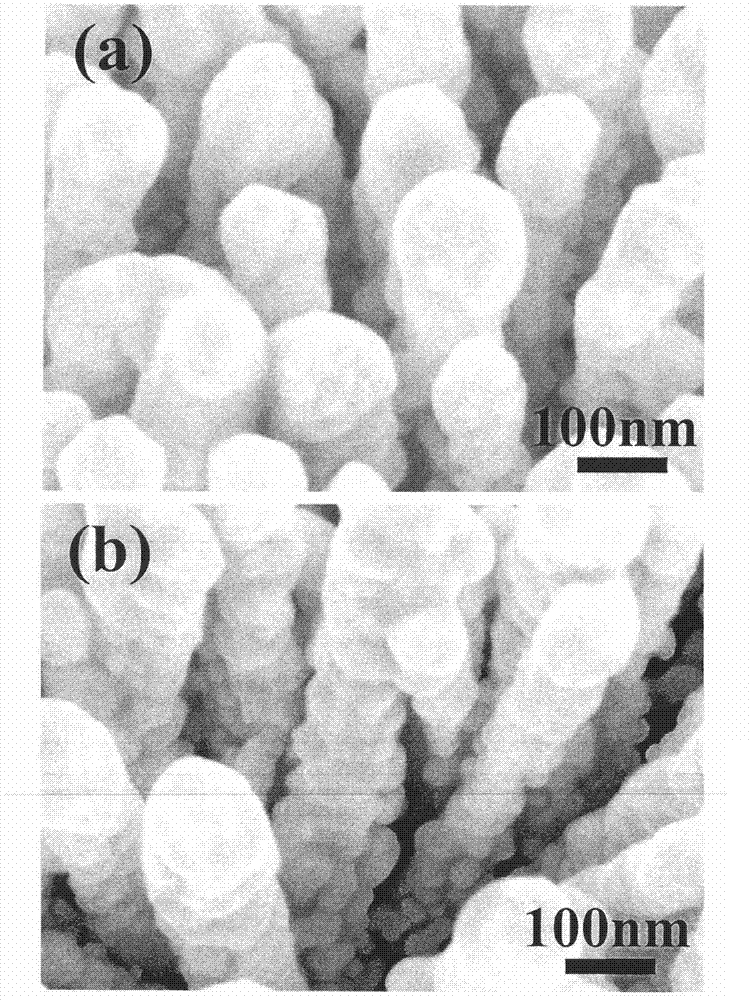

[0032] Step 2. Place the substrate covered with the zinc oxide seed layer in a zinc nitrate ammonia complex solution with a temperature of 75°C and a concentration of 0.03 mol / L, using it as the cathode and graphite sheet as the anode. 0.3mA / cm 2 Electrodeposition was carried out for 5 hours to obtain a substrate on which an array of zinc oxide nanorods with sharp tops was placed; wherein the zinc nitrate ammonia complex solution was prepared by gradually injecting ammonia into the stirred zinc nitrate solution, Until it changes from turbid to clear.

[0033] Step 3. Place ...

Embodiment 2

[0035] The specific steps of preparation are:

[0036] Step 1. First, apply a zinc acetate ethanol solution with a concentration of 13 mmol / L to the substrate, and then wash and disperse it with ethanol after drying; where the substrate is a silicon wafer. The substrate with zinc acetate placed on it was thermally decomposed at 320° C. for 23 minutes, and the above-mentioned coating, dispersion and thermal decomposition process was repeated twice to obtain a substrate covered with a zinc oxide seed layer.

[0037] Step 2. Place the substrate covered with the zinc oxide seed layer in a zinc nitrate ammonia complex solution with a temperature of 79°C and a concentration of 0.04 mol / L, using it as the cathode and graphite sheet as the anode. 0.4mA / cm 2 Electrodeposition for 4.5 hours to obtain a substrate on which an array of zinc oxide nanorods with sharp tops is placed; wherein the zinc nitrate ammonia complex solution is prepared by gradually injecting ammonia into the stirred zinc...

Embodiment 3

[0040] The specific steps of preparation are:

[0041] In step 1, first coat a zinc acetate ethanol solution with a concentration of 16 mmol / L on the substrate, and then wash and disperse it with ethanol after it is dried; where the substrate is a silicon wafer. The substrate with zinc acetate placed on it was thermally decomposed at 335°C for 22 minutes, and the coating, dispersion and thermal decomposition process was repeated three times to obtain a substrate covered with a zinc oxide seed layer.

[0042] Step 2. Place the substrate covered with the zinc oxide seed layer in a zinc nitrate ammonia complex solution with a temperature of 83°C and a concentration of 0.05 mol / L, using it as the cathode and graphite sheet as the anode. 0.5mA / cm 2 Electrodeposition was carried out for 4 hours to obtain a substrate on which an array of zinc oxide nanorods with sharp tops was placed; wherein the zinc nitrate ammonia complex solution was prepared by gradually injecting ammonia into the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com