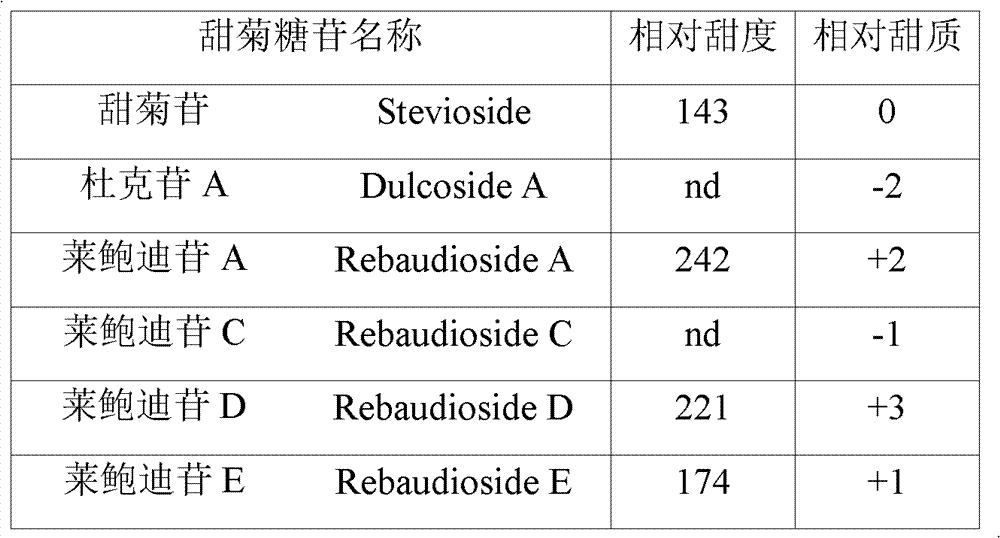

Stevia rebaudiana enzyme VI and method for converting rebaudioside-A into rebaudioside-D

A technology of stevia enzyme and stevia, applied in the direction of transferase, fermentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0054] Example 4 Investigating the influence of filtration and concentration on the RD content of solids

[0055] After obtaining the reaction solution according to the conversion method of Examples 1-18, if filter paper is used and dried, solid substance A is obtained; if 10kD ultrafiltration membrane is used for ultrafiltration, the permeate is dried to obtain solid substance B; The ultrafiltrate was recrystallized and dried to obtain the solid substance C. The RD was detected by the HPLC detection method in the national standard GB8270-1999. The results are shown in Table 5.

[0056] table 5

[0057]

[0058] It can be seen from Table 5 that the content of rebaudioside D in the solid A can reach at least 60%, and the RD of the solid C red after further purification can reach 80%, or even greater than 90%.

[0059] In summary, using the above-mentioned enzyme catalysis and separation method, the conversion rate of rebaudioside D obtained from rebaudioside A as raw material is ≥70%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com