Method and device for fully automatically and accurately monitoring changes of geometric parameters of track

A geometric parameter and fully automatic technology, applied in the field of track measurement, can solve the problems of inability to realize all-weather, fully automatic detection, increase the unsafety of online operations, and high requirements for working hours, so as to improve the railway construction environment and lines Monitoring level, avoiding on-track measurement, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following embodiments.

[0017] The method for fully automatic and precise monitoring of changes in track geometric parameters described in this embodiment includes monitoring of horizontal displacement, monitoring of vertical displacement, data collection, transmission and processing.

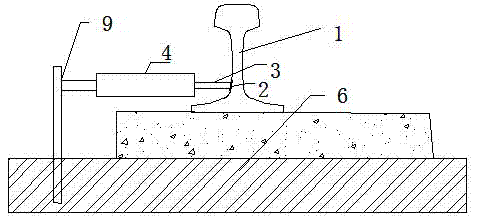

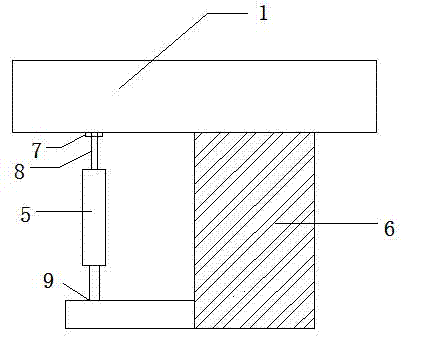

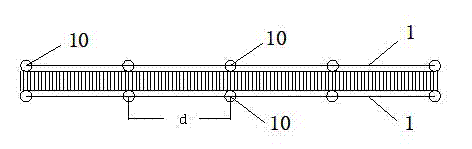

[0018] Such as Figure 1-3 As shown, the monitoring of the horizontal displacement is to arrange a pair of track monitoring points 10 at intervals of a certain distance d along the longitudinal direction of the track 1. In this embodiment, a pair of track monitoring points 10 are set at intervals of 4-8m. The calculation basis stipulated in the "Railway Revision Rules" is that the track direction and height are both based on the chord length of 10m as the calculation unit, the twist is based on 6.25m as the calculation base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com