Construction method for inclined tensioning reinforcing bar type and overhanging section steel scaffold

A technology of cantilevered scaffolding and construction methods, which is applied in the direction of scaffolding supported by house structures, house structure supports, house structure supports, etc., can solve problems such as high steel prices, high construction costs, and deformation of supports, and achieve good economic benefits and construction Simple process, solve the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

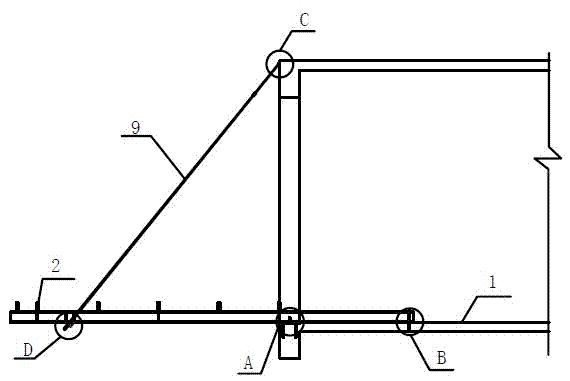

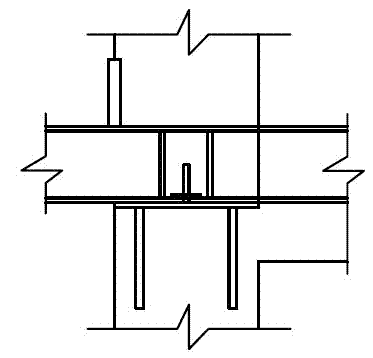

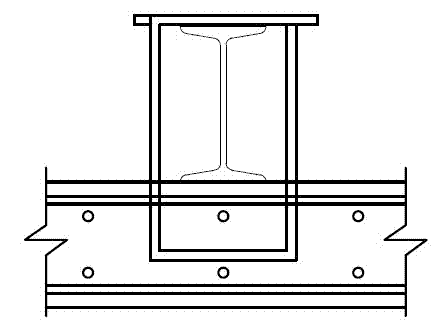

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the construction method of steel bar cable-stayed section steel cantilevered scaffolding, the embedded parts A and B are pre-embedded in floor 1 when pouring concrete on the floor where the section steel support is located; when pouring concrete on the cable-stayed steel anchor floor, the cable-stayed steel anchor section 3 Pre-buried in the side beam 4; weld the shaped steel beam on the ground with ribbed double-angle steel 7, and weld the steel bar head 2 at the upper end, and the steel bar head is used to fix the scaffold; hoist the shaped steel beam to the floor 1 where the shaped steel support is located, one end Weld and fix with embedded parts A and B; connect one end of the cable-stayed steel bar 9 with the pre-embedded steel bar 6 on the upper layer with sleeve I5, insert the other end into the reserved hole 8 of the double-angle steel under the steel beam, and fix it with sleeve II1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com