Construction method for building ground inlet and outlet type shield tunnel

A construction method and access technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of long engineering cycle, large amount of engineering, waste, etc., to save engineering construction cost, shorten construction period, and reduce impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] For the benefit of a further understanding of the structure of the present invention, the present invention uses Figure 1~Figure 6 A preferred embodiment of the description.

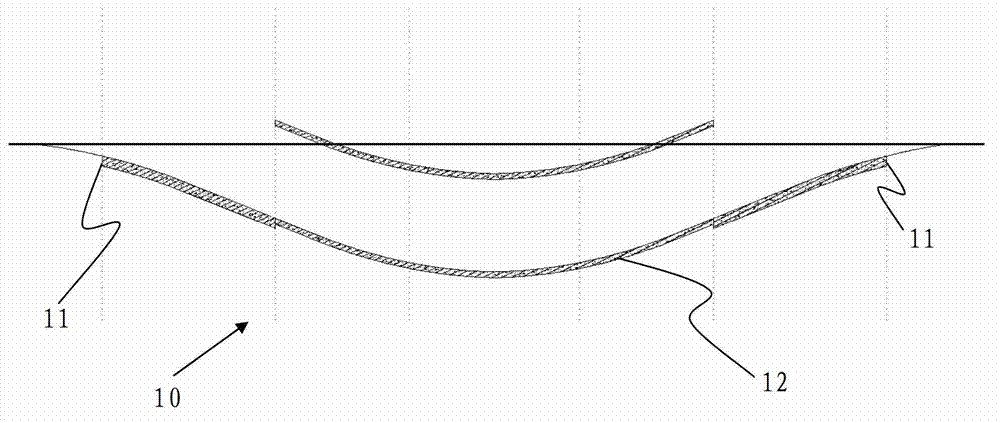

[0032] see first figure 1 As shown, the axis of the ground access shield tunnel 10 of the present invention is a line shape from the ground to the underground, and the shield tunnel 10 includes a junction section tunnel 11 for access to the ground and an ultra-shallow soil-covered section tunnel 12 .

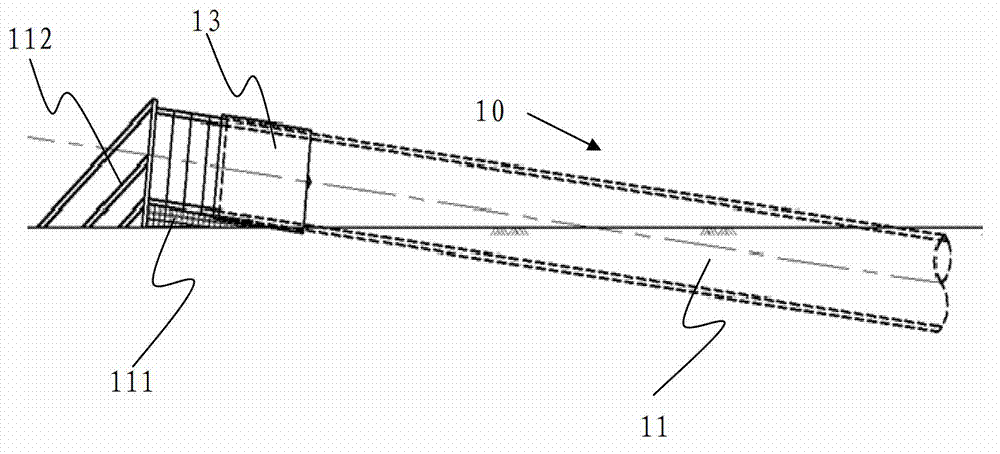

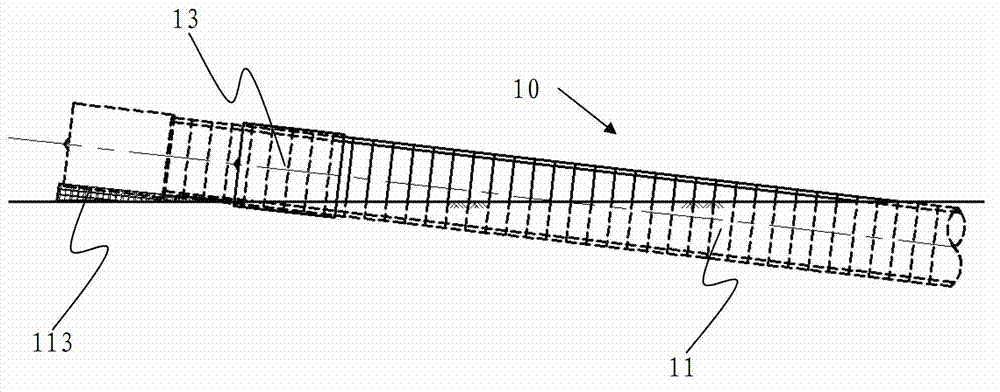

[0033] The shield can be initiated and received directly from the ground, such as figure 2 , image 3 shown. It is also possible to set a shallow buried pilot pit on the ground, and the shield tunnel starts and receives in the shallow buried pilot pit, such as Figure 4 , Figure 5 , Image 6 shown.

[0034] Cooperate figure 2 As shown, along the axis of the tunnel line, the shield starting base 111 and the backing support system 112 are respectively set at the starting position of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com