Compressor, manufacturing method and application of compressor

A manufacturing method and compressor technology, applied in the field of compressors, can solve the problems of high requirements for welding end surface processing and cleaning, uneven heating of contact surfaces, lack of non-destructive testing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described in conjunction with the following examples.

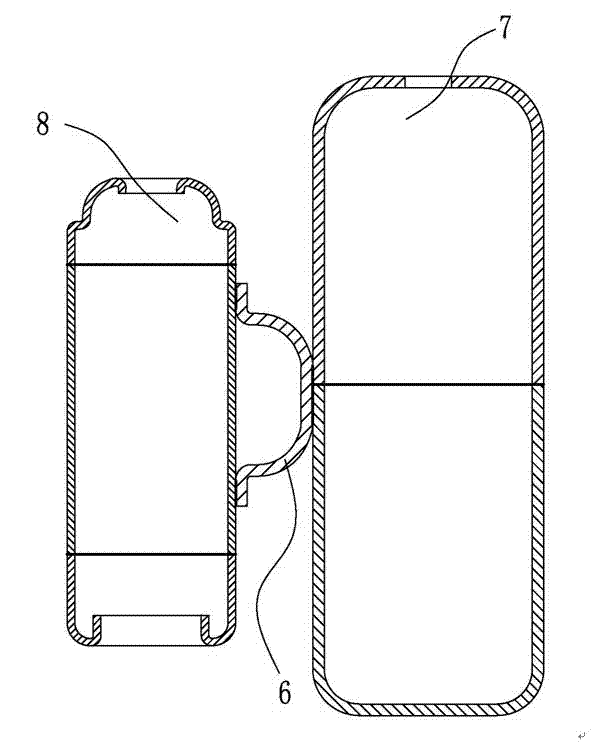

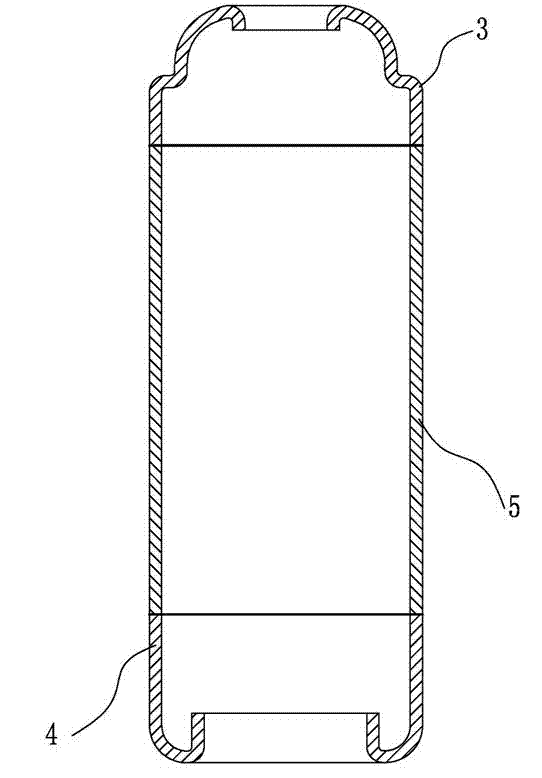

[0034] a compressor such as figure 1 As shown, it includes a compressor casing 7 and an accumulator casing 8 .

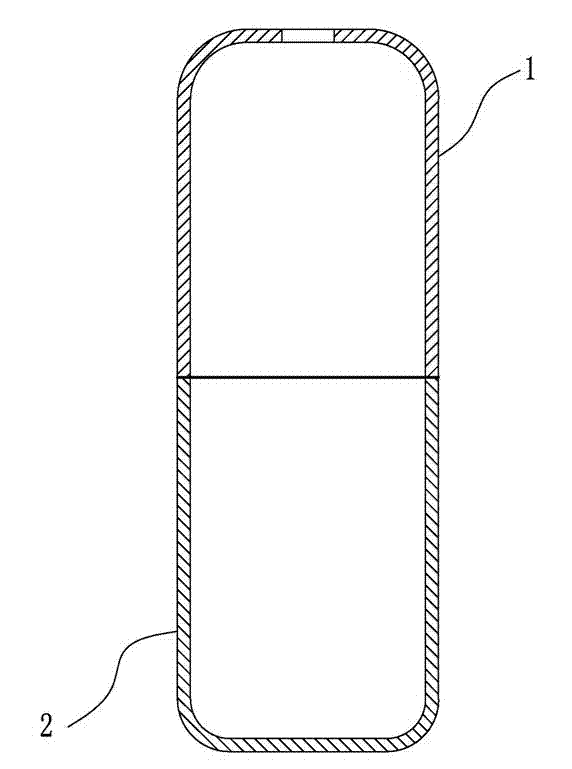

[0035] Compressor housing 7, such as figure 2 As shown, it is composed of the upper cover 1 of the compressor and the lower cover 2 of the compressor. Both the upper cover 1 of the compressor and the lower cover 2 of the compressor are made of iron materials. The inner diameter of one butt end is smaller than the outer diameter of the other butt end. Preferably, the butt ends of the compressor upper cover 1 and the compressor lower cover 2 have the same setting, and the butt ends are welded by flash welding. The specific steps of the method are as follows :

[0036] a. Preheating: after the compressor upper cover 1 and the compressor lower cover 2 are butt-fitted in the clamp for welding the secondary connection of the transformer, a large current is applied to it, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com