Dodging lens, backlight module using dodging lens and display device

A technology of uniform light lens and backlight module, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of difficult thin design of backlight modules, expensive uniform light lens, etc., and achieve the effect of light output. Good, cost reduction, product cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

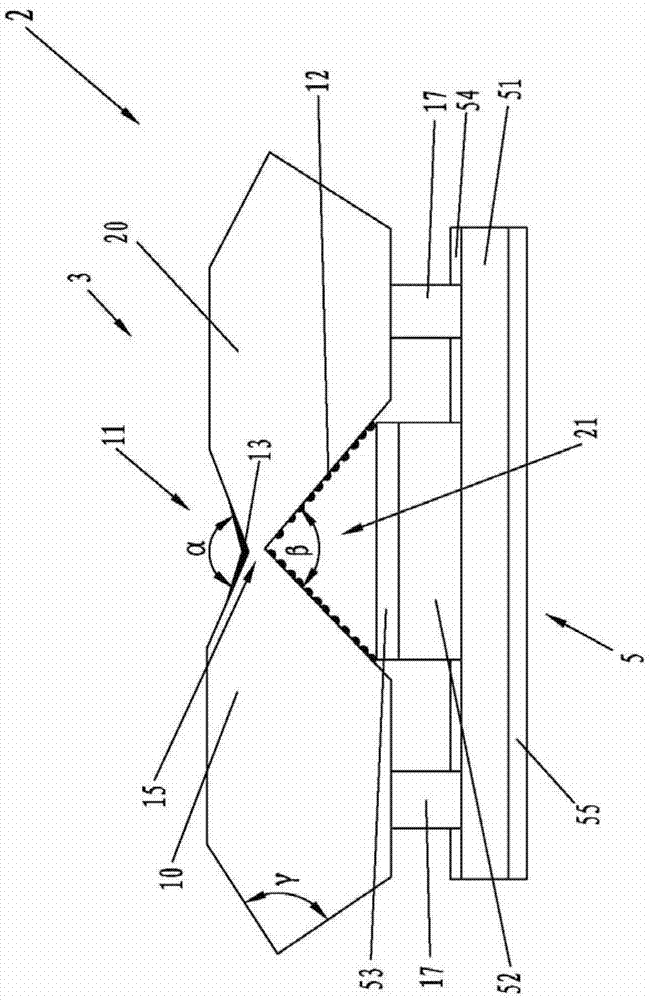

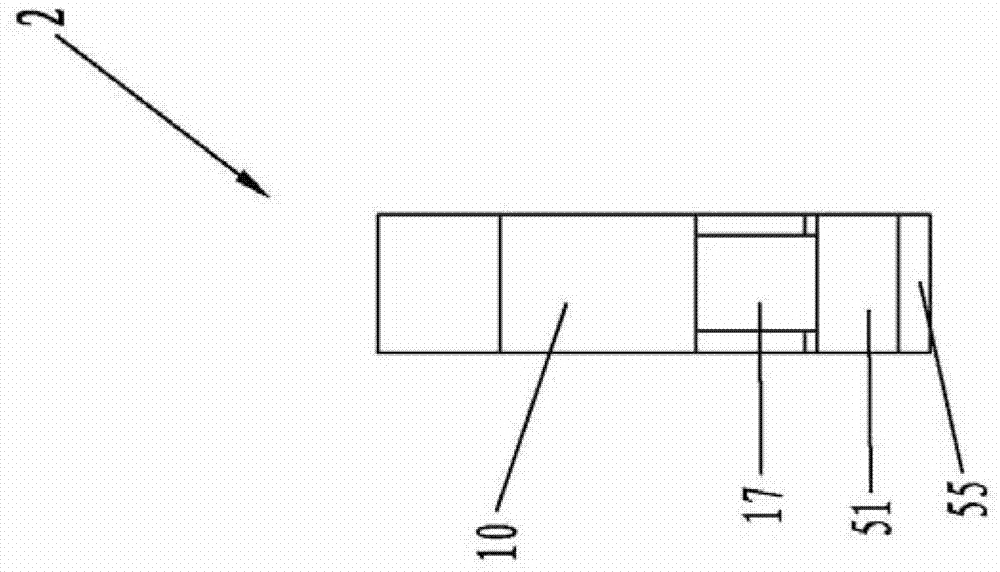

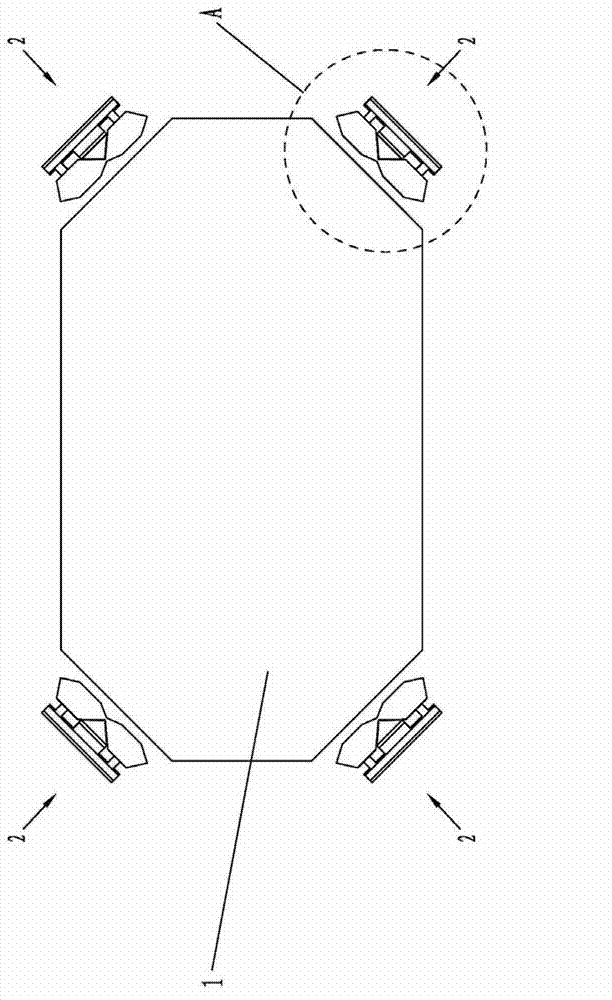

[0037] Such as figure 1 , image 3 , Figure 4 As shown, the embodiment of the backlight module using uniform light lens of the present invention includes a light guide plate 1 and a light source device 2 disposed on the side of the light guide plate 1 . The light source device 2 comprises the uniform light lens 3 of the present invention and the light source 5 arranged inside the second V-shaped groove 21 of the uniform light lens 3, and the opening of the first V-shaped groove surface 11 of the uniform light lens 3 faces the opening of the light guide plate 1. side.

[0038] combine figure 2 As shown, the homogenizing lens 3 includes a first sheet 10 and a second sheet 20 both of which are hexagonal. The first sheet 10 and the second sheet 20 are located at the same height and are arranged side by side. One corner of the first sheet 10 is connected to a corresponding corner of the second sheet 20 to form a second sheet above the connection point. A V-shaped groove 11 a...

Embodiment 2

[0072] The specific structure of the homogenizing lens of the present invention should match the model selected by the LED lamp, that is, the specific size of the homogenizing lens varies with the size of the selected LED.

[0073] Figure 5 The specific structural dimensions of another embodiment of the uniform light lens of the present invention are shown. The difference between the uniform light lens 3' of this embodiment and the uniform light lens 3 in the first embodiment is that the first V-shaped groove 11 ' and the second V-shaped groove 21' are circular arc grooves with a circular arc cross section.

[0074] In the uniform light lens 3', the first sheet 10' and the second sheet 20' are left-right symmetrical with the vertical central axis 70' as the axis of symmetry.

[0075] The thickness of the homogenizing lens 3' of the present embodiment is consistent with that of the LED lamp 52', both being 1.4 millimeters. The groove bottom of the first V-shaped groove 11' i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com