Automatic feeding and discharging device for freeze dryer

A technology for feeding and discharging materials and freeze dryers, which is applied in the directions of drying solid materials, drying, lighting and heating equipment, etc. It can solve the problems of high precision requirements for parts production, easy contamination of medicines in the box, and complicated installation process, etc. , to achieve the effect of saving the space of the sterile room, saving the manufacturing cost and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

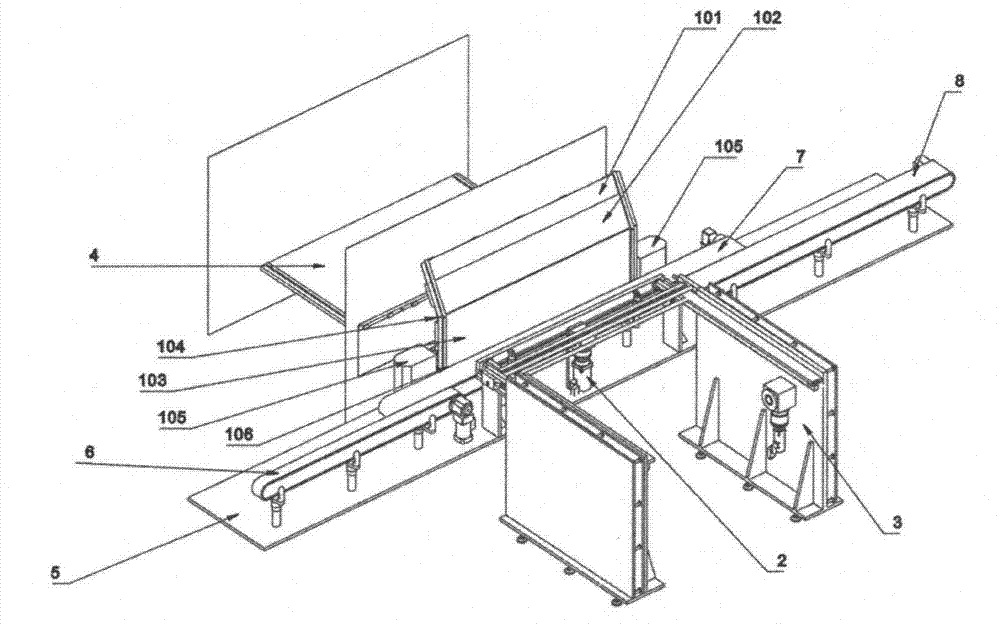

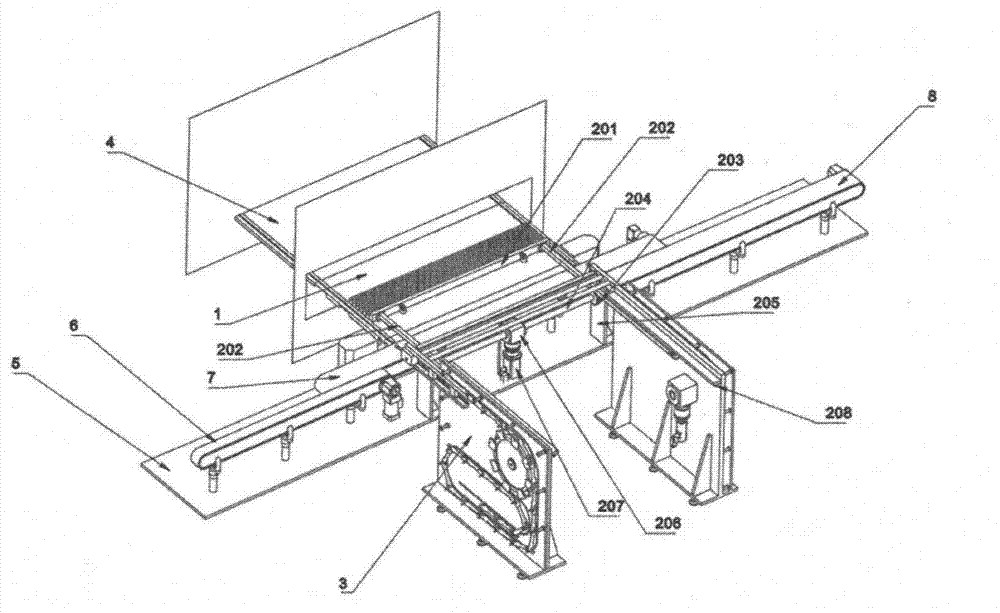

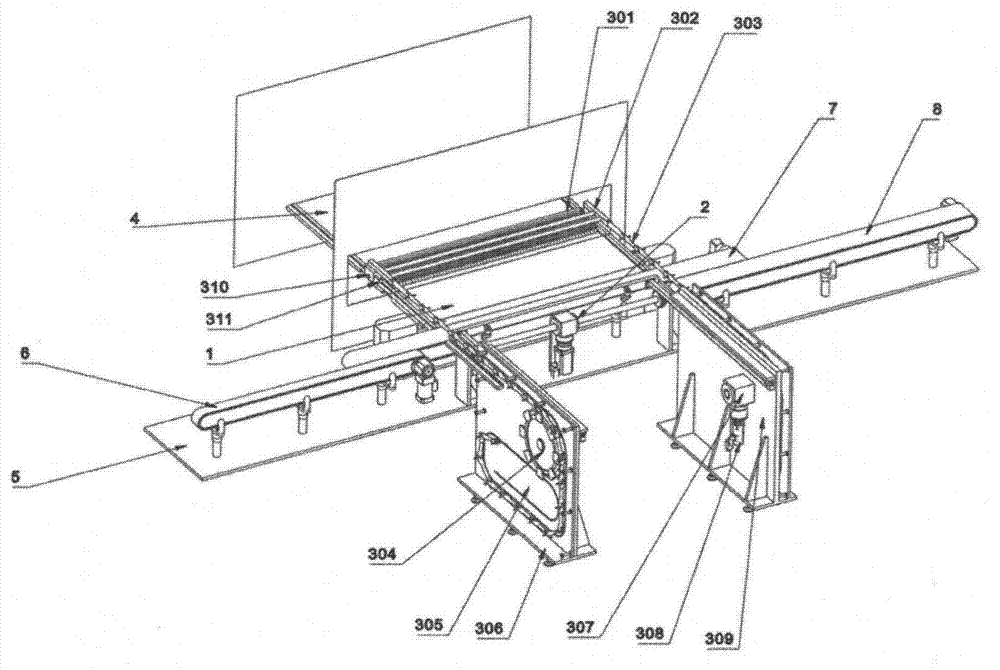

[0025] An automatic feeding and discharging device for a freeze dryer, which consists of a folding transition bridge system 1, a bottle unscrambling system 2, a flexible multi-section rod system 3, a fixed bottom plate 5, a bottle inlet mesh belt 6, a bottle unscrambling mesh belt 7, and a bottle outlet mesh It consists of 8 belts and a servo control system. Among them, the folding transition bridge system 1, the bottle unscrambling system 2, the bottle inlet mesh belt 6, the bottle unscramble mesh belt 7 and the bottle outlet mesh belt 8 are arranged on the fixed bottom plate 5, the bottle inlet mesh belt 6, the bottle unscramble mesh belt 7 and the bottle outlet mesh belt The bottle mesh belt 8 is arranged in turn, the front side of the bottle mesh belt 7 is provided with a folding transition bridge system 1, and the bottle mesh belt 7 is provided with a bottle system 2 and a flexible multi-section rod system 3 at the rear side. The foldable transition bridge system 1 mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com