Method for designing continuous titration chemical analysis scheme of sodium aluminate solution

A technology of sodium aluminate and solution, which is applied in the direction of analyzing materials through chemical reactions and analyzing materials through observing the influence of chemical indicators, which can solve the problems of no performance advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

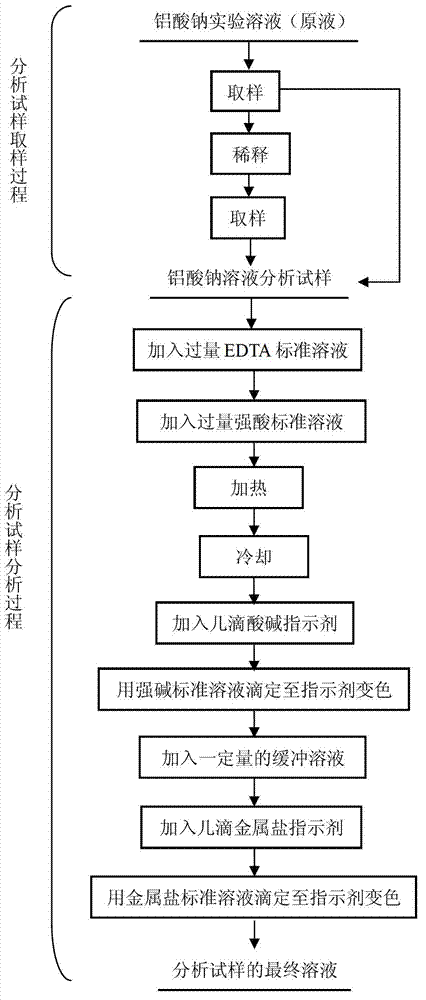

Method used

Image

Examples

Embodiment 1

[0040] This embodiment specifically illustrates the design of a chemical analysis scheme suitable for the scientific research process according to the content of the invention.

[0041] The sodium aluminate solution experimental condition and sampling standard that embodiment is aimed at are as shown in table 7:

[0042] Table 7 Experimental conditions and sampling standards of the scientific research process

[0043]

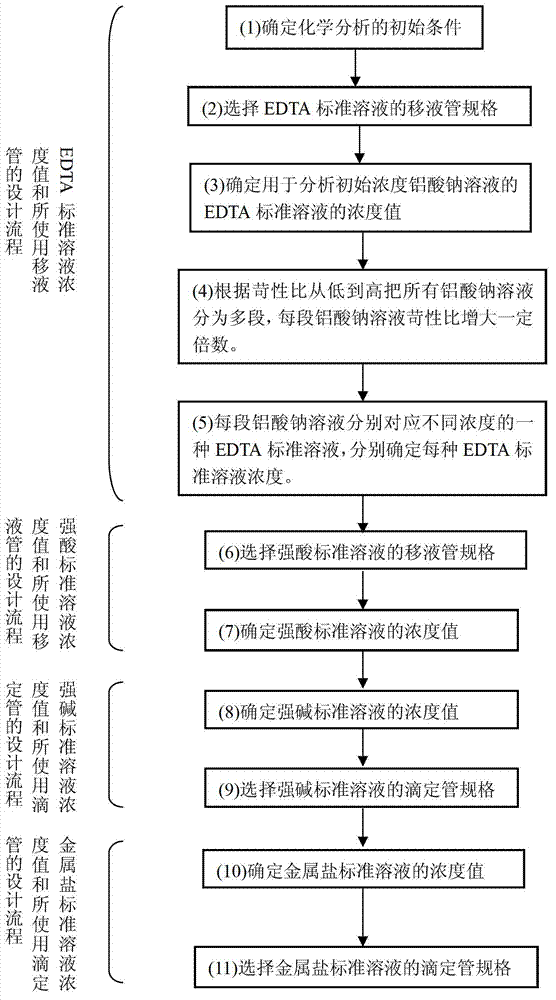

[0044] According to attached figure 2 The flow chart shown is used to design a chemical analysis scheme suitable for the scientific research process: (1) The sampling standard of the above sodium aluminate solution analysis sample is equivalent to 2×(1 / 5)=0.4 ml of the sodium aluminate stock solution, that is, at the initial The concentration of sodium aluminate solution analysis sample contains about 0.4×2.5=1.0 mmol of Al, and about 0.4×4=1.6 mmol of total alkali. (2) According to the present invention, the EDTA standard solution adopts a 20 ml grade A ...

Embodiment 2

[0053] This example specifically illustrates the design of a chemical analysis scheme suitable for the production process based on the content of the invention.

[0054] The sodium aluminate solution production condition that embodiment is aimed at and sampling standard are as shown in table 10:

[0055] Table 10 Production conditions and sampling standards of the production process

[0056]

[0057]The production process adopts a chemical analysis scheme different from that of the scientific research process, and its determination method is as follows: ① The sampling standard for the analysis sample in the production process is 2.0 ml of sodium aluminate stock solution, that is, the amount of Al in the analysis sample of the initial concentration of sodium aluminate solution The content is about 2.0×2.5=5.0 mmol, and the content of total alkali is about 2.0×4.0=8.0 mmol. Compared with the chemical analysis in the scientific research process, the sampling volume of the ana...

Embodiment 3

[0066] This example specifically illustrates the practical application of the continuous titration chemical analysis scheme for each component of the sodium aluminate solution proposed by the present invention.

[0067] According to the present invention, the chemical analysis scheme adopted in the example is shown in Table 13, and the specific steps of the analysis operation are as described in Example 1. The actual error of the chemical analysis scheme is shown in Table 14, and the results show that the maximum error of the chemical analysis is about 0.6%. Compared with the traditional chemical analysis scheme, the overall analysis error is greatly reduced.

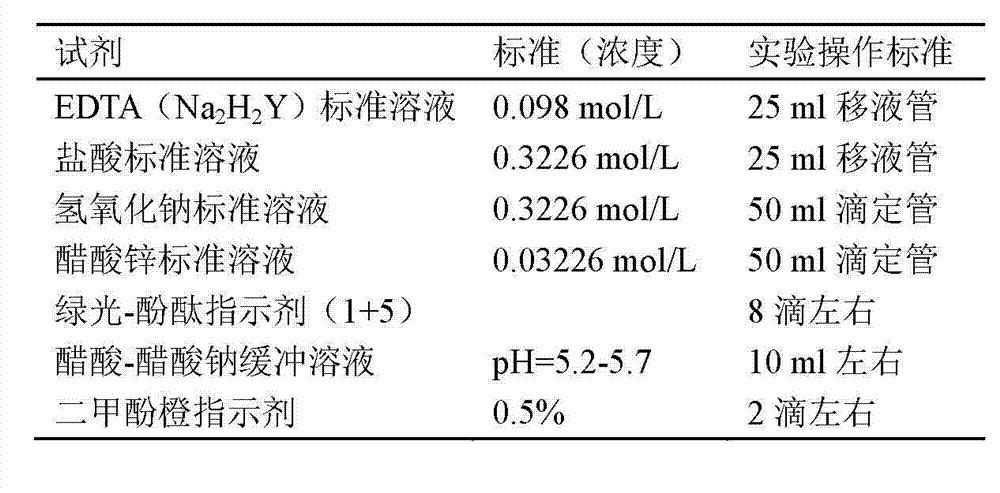

[0068] Table 13 The chemical analysis scheme actually used in a scientific research process

[0069]

[0070] Table 14 The actual error of the chemical analysis scheme actually used

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com