Brightening membrane and backlight module and display device

A technology of backlight module and brightness enhancement film, which is applied in optics, optical components, nonlinear optics, etc., can solve the problem of poor gain effect, achieve the effect of improving gain characteristics and reducing overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

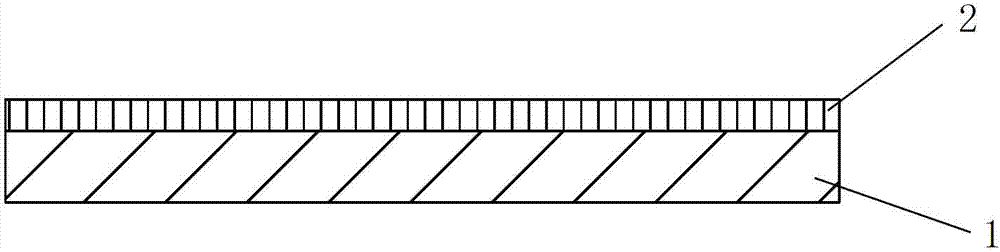

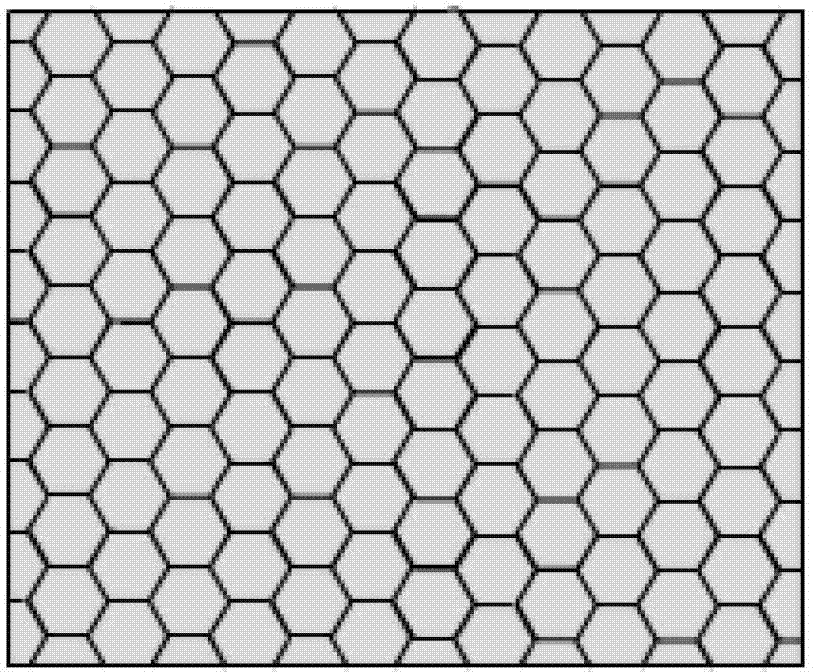

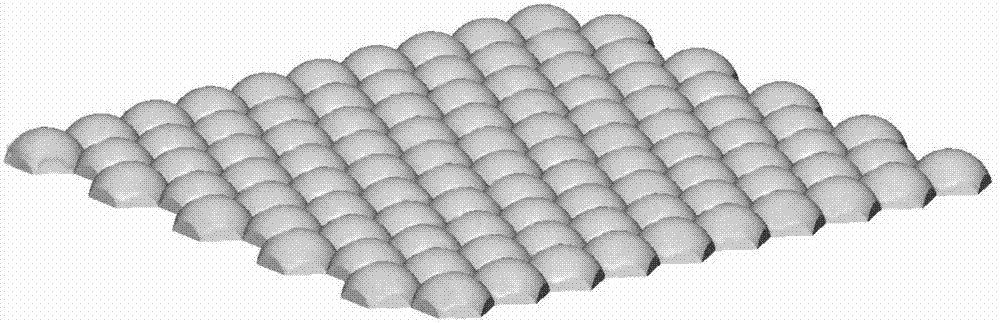

[0029] like figure 1 and refer to Figure 2-Figure 3 As shown, the present invention provides a brightness-enhancing film, including a substrate 1 and a microlens 2 formed on the substrate. The microlens 2 includes: a plurality of optical unit structures, and each optical unit structure is in contact with the substrate. The bottom surface is polygonal, and an arc structure corresponding to the shape of the bottom surface is formed on the bottom surface; each optical unit structure is closely connected with its surrounding adjacent optical unit structures.

[0030] Preferably, the bottom surface of each optical unit structure in contact with the base is a regular hexagon, and each optical unit structure has the same size.

[0031] like Figure 4-Figure 6 As shown, preferably, the arc-shaped structure is a convex lens.

[0032] The diaphragm 41 is made of PET (polyethylene terephthalate), PC (polycarbonate) or PS (polystyrene), preferably made of PET material, and the optical...

Embodiment 2

[0034] The brightness-enhancing film of this embodiment has basically the same structure as that of Embodiment 1, including a substrate 1 and a microlens 2 formed on the substrate. The microlens 2 includes: a plurality of optical unit structures, each optical unit structure and the The bottom surface in contact with the base is polygonal, and an arc structure corresponding to the shape of the bottom surface is formed on the bottom surface; there is no gap between each optical unit structure and its surrounding adjacent optical unit structures.

[0035] The difference is that: the bottom surface of each optical unit structure in contact with the base is an equilateral triangle and the size of each optical unit structure is the same; the arc-shaped structure is a concave lens.

[0036] The diaphragm 41 is made of PET (polyethylene terephthalate), PC (polycarbonate) or PS (polystyrene), preferably made of PET material, and the optical unit structure is made of organic Made of gla...

Embodiment 3

[0038] The brightness enhancing film of this embodiment has basically the same structure as that of Embodiment 1 and Embodiment 2, including a substrate 1 and a microlens 2 formed on the substrate. The microlens 2 includes: a plurality of optical unit structures, each optical The bottom surface of the unit structure in contact with the base is polygonal, and an arc structure corresponding to the shape of the bottom surface is formed on the bottom surface; there is no gap between each optical unit structure and its surrounding adjacent optical unit structures.

[0039] The difference is that: the bottom surface of each optical unit structure in contact with the base is square and the size of each optical unit structure is the same; the arc-shaped structure is a convex lens.

[0040] The diaphragm 41 is made of PET (polyethylene terephthalate), PC (polycarbonate) or PS (polystyrene), preferably made of PET material, and the optical unit structure is made of organic Made of glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com