Large power semiconductor laser with stable light spots

A high-power, semiconductor technology, used in semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve problems that will affect the optical path, the impact of optoelectronic integration applications, and the addition of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

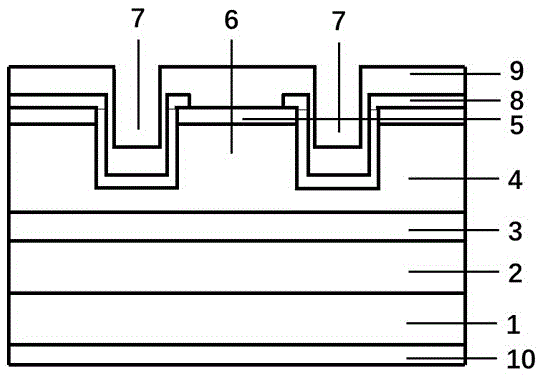

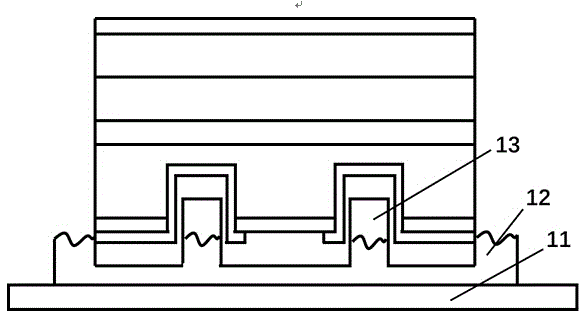

[0020] like figure 1 As shown, the spot-stabilized high-power semiconductor laser of the present invention includes a substrate 1 , a lower cladding layer 2 , an active region 3 , an upper cladding layer 4 and a contact layer 5 from bottom to top. Substrate 1 is a common GaAs substrate. The lower cladding layer 2, the active region 3 and the upper cladding layer 4 are made of AlGaInP material lattice-matched with the GaAs substrate, and the emission wavelength is about 650nm. The contact layer 5 is GaAs heavily doped with Zn, and the doping concentration is 1×10 19 ~1×10 20 cm -3 . The total thickness of the upper cladding layer 4 and the contact layer 5 is 2-3 μm.

[0021] A ridge structure 6 is formed on the upper cladding layer 4 and the contact layer 5 by wet etching or dry etching, and grooves 7 are formed on both sides of the ridge structure 6 . To satisfy high power output, the width of the ridge structure 6 is 50-150 μm, and the width of the groove 7 is 10-30 μm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com