Method for preparing polymeric microspheres and polymeric microspheres produced thereby

A technology for polymer microspheres and polymer compounds, which is applied in the field of preparation methods and polymer microspheres prepared by the method, can solve problems such as poor mixing, decreased drug release reproducibility, and low water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

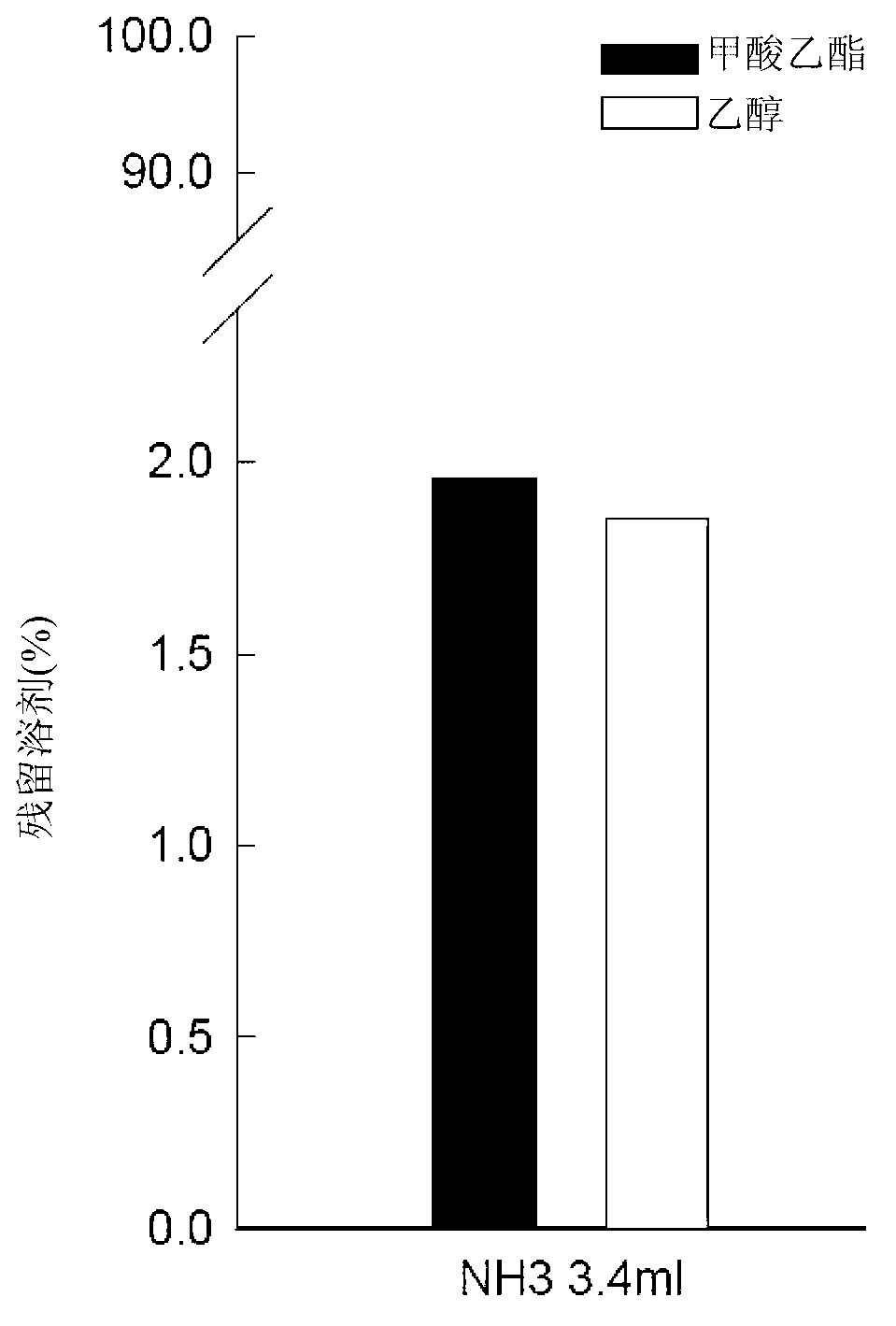

[0121] Contrast experiment of residual solvent concentration under different concentrations of water-insoluble organic solvent mixed in dispersion solvent

[0122] Measurement of residual solvents when preparing polymer microspheres according to the original method

[0123] An emulsion was prepared by dissolving 0.25 g of 75252.5E PLGA polymer in 4 ml of ethyl formate (EF) and emulsifying it in 40 ml of 0.5% polyvinyl alcohol (PVA). Then, 3.4 ml of 28% NH3 solution was added to the emulsion, reacted for 30 minutes, and filtered after adding distilled water. The microspheres were separated, redispersed in 0.1%PVA80ml and stirred. Information on the 7525 2.5E PLGA polymer used for this experiment is as follows.

[0124] 【Table 1】

[0125] 75252.5E PLGA polymer information

[0126]

[0127] The microsphere residual solvent analysis used the following gas chromatography (GC) method. The GC equipment used GC-2010 of Shimadzu Corporation (Japan), and the column used ZB-624 ...

Embodiment 2

[0139] Contrast experiment of residual solvent concentration at different dispersing solvent temperatures in the redispersing step

[0140] When preparing polymer microspheres, the temperature of the water phase changes due to the reaction of acids or bases used to remove water-insoluble organic solvents, and this is expected to affect the amount of residual solvents. Therefore, the preparation process of polymer microspheres is separated, and the time point until the addition of alkali or acid solution and the reaction is terminated is defined as step 1, and the polymer microspheres separated by filtration are redispersed in the PVA solution after the reaction is terminated. And the time point at which the stirring is terminated is defined as step 2. It is known that temperature in any of these steps plays an important role in reducing residual solvents.

[0141] Comparative experiment of residual solvent concentration at different dispersion solvent temperatures in the redi...

Embodiment 3

[0175] Contrast experiment of residual solvent concentration under different concentrations of water-insoluble organic solvent mixed in dispersion solvent 1

[0176] In the aforementioned , it was confirmed that the concentration of the residual organic solvent decreased when the organic solvent was previously added to the dispersion solvent. Therefore, using different amounts of the water-insoluble organic solvent mixed in the dispersion solvent while maintaining the temperature of the dispersion solvent in the redispersion step high, the corresponding residual solvent amounts were measured and compared.

[0177] Dissolve 500mg of 4.5A PLGA (lactide:glycolide=85:15, 0.45dL / g, SurModics Pharmaceutical Company, the U.S.) in 4ml of ethyl formate to make a dispersed phase, and make the dispersed phase separately in advance It was emulsified in 20 ml of 0.5% PVA aqueous solution to which 0, 1, 2 or 4 ml of ethyl formate was added to prepare an emulsion. Then, 6.2 ml of 10N NaOH w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com