Bean grinding coffee maker and method thereof

A coffee and machine technology, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as complex structure and increased manufacturing costs, and achieve the effects of low cost, improved production efficiency, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

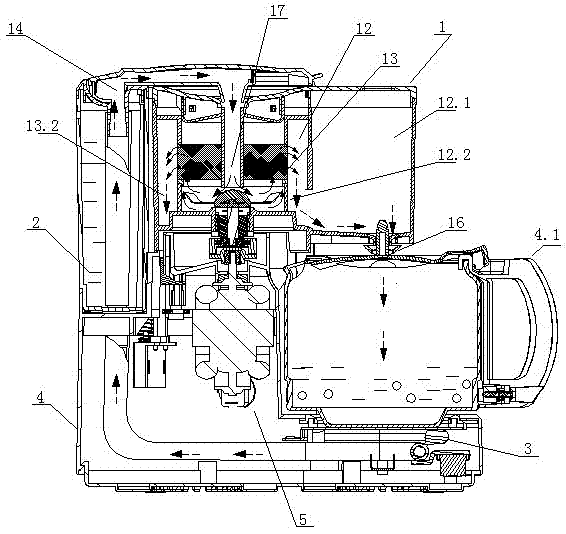

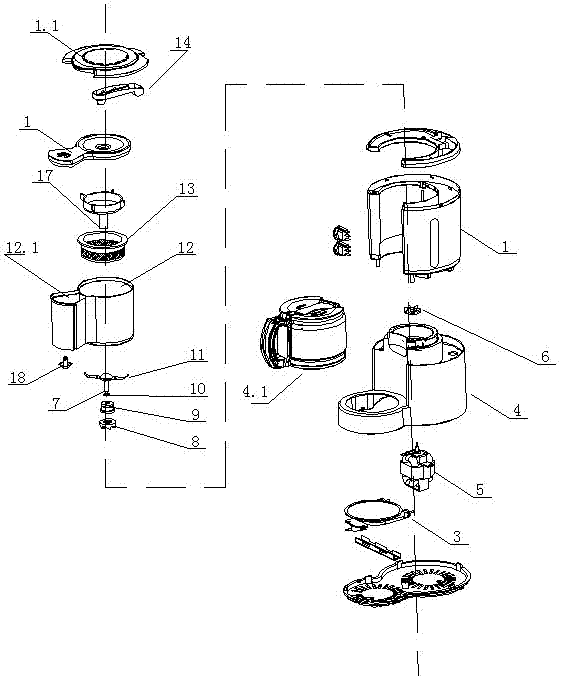

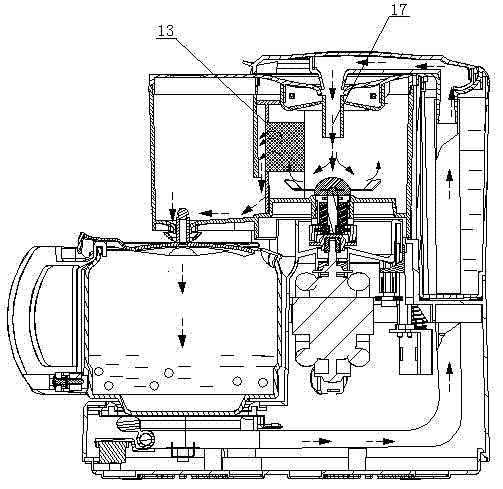

[0027] see Figure 1-Figure 6 , the present coffee grinder includes a water tank 2 and a heater 3 arranged in an outer casing 4, and the water tank 2 is connected to the heater 3. The top of the outer shell 4 is provided with an outer cover 1.1, and the outer cover 1.1 is hingedly connected with the outer shell 4, and the outer cover 1.1 and the outer shell 4 form a coffee machine body. The main body of the coffee machine is equipped with a crushing container that is movably connected with it, the purpose of which is to allow the coffee machine to use coffee beans or coffee powder to brew coffee, thereby expanding the scope of application of the product and meeting the needs of different users. The main body of the coffee machine is provided with a driving assembly corresponding to the pulverizing container, and the motor 5 of the driving assembly is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com