Rolling mill capable of being used in vertical and horizontal rolling manners

A rolling mill, vertical and horizontal technology, applied in the field of steel rolling equipment, can solve problems such as uneven structure and performance, single rolling method, deterioration of mechanical properties, etc., achieve high rigidity, strong adaptability of rolling mill, and improve rolling quality and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

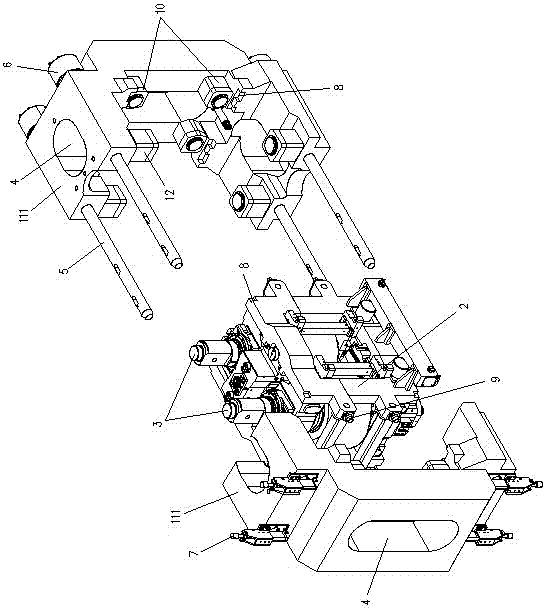

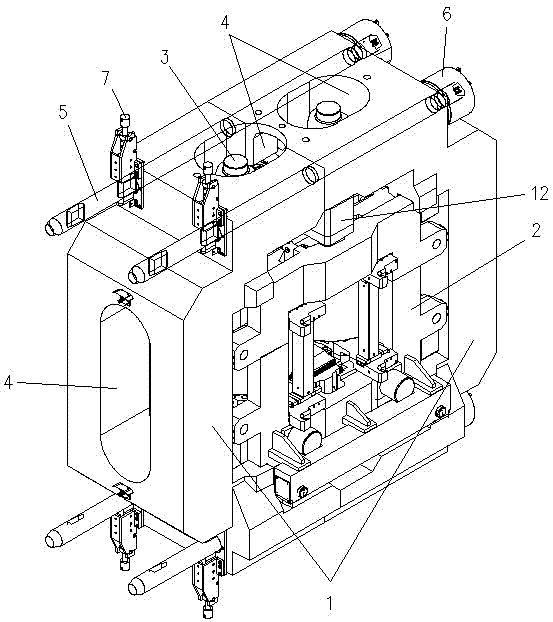

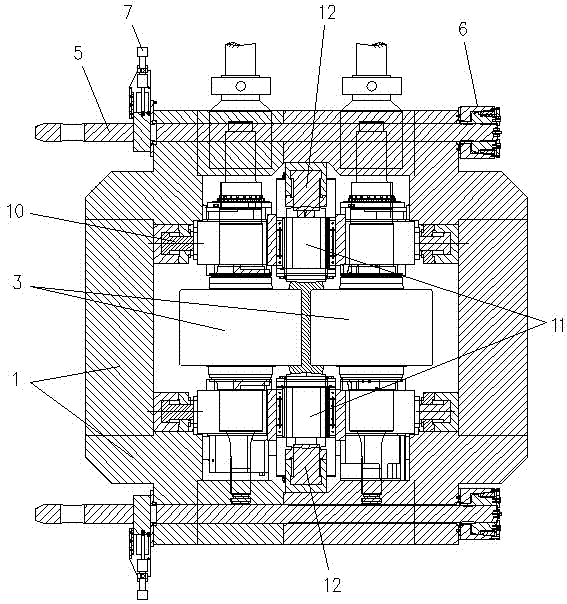

[0021] Such as figure 1 As shown, the rolling mill that can be used for vertical and horizontal rolling in this embodiment includes a frame assembly and a roll assembly, and the frame assembly includes a die frame 1 for fixing the roll assembly, and the die frame 1 is composed of two half The frame 111 is detachably connected by connecting parts, and the roll assembly includes a roll frame 2 and two driving rolls 3 arranged on the roll frame 2, and the roll frame 2 can be vertically arranged according to the driving roll 3 (such as figure 1 , 2 , shown in 3 and 4) and the driving roll 3 are arranged horizontally (such as Figure 5 and 6 Shown) two ways are fixed in the mouth shape window of the mouth shape frame 1.

[0022] In specific implementation, the driving roll 3 may be arranged vertically or horizontally according to the technical requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com