Abrasion resistant magnetic force rotatable feeder

A rotary feeder, magnetic technology, applied in metal processing and other directions, can solve the problems of the feeder being unable to count workpieces, the wall wear of the feeder, noise pollution, etc., to achieve simple structure, convenient and fast feeding, and low wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

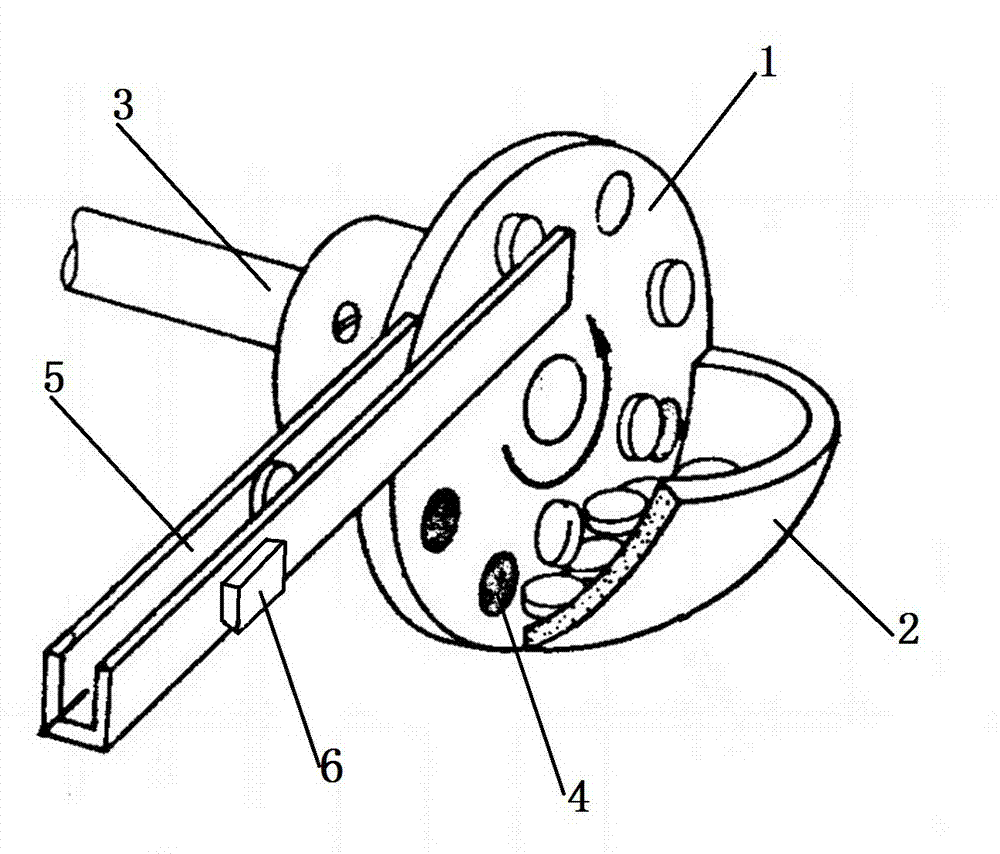

[0010] refer to figure 1 , a wear-resistant magnetic rotary feeder, including a circular rotating plate 1, the outer side of the rotating plate 1 is a feeding bowl 2 with a circular workpiece, the feeding bowl 2 is half a bowl, and the feeding A wear-resistant layer made of rubber is attached to the inner wall of the feeding bowl 2, and the left end surface of the feeding bowl 2 is in close contact with the outside of the rotating plate 1, and the upper end is open.

[0011] The inner side of the rotating plate 1 is connected with a rotating shaft 3, and the outer circumference of the rotating plate 1 is provided with a workpiece groove 4. The workpiece groove 4 has a cylindrical magnet wall cover. The depth of the workpiece groove 4 is smaller than the thickness of the workpiece, and the workpiece can be sucked In the workpiece groove 4 and partially emerge from the workpiece groove 4, the upper part of the outer side of the rotating plate 1 is in close contact with a U-shape...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap