Method for controlling concrete precooling slump by monitoring current intensity of stirrer

A current intensity and concrete technology, applied in the direction of control devices, etc., can solve the problems that cannot fully reflect the concrete slump and changes, heavy workload, and the concrete state cannot be adjusted in time, so as to increase the production efficiency of concrete and improve the quality of concrete. efficiency and the effect of reducing the amount of staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

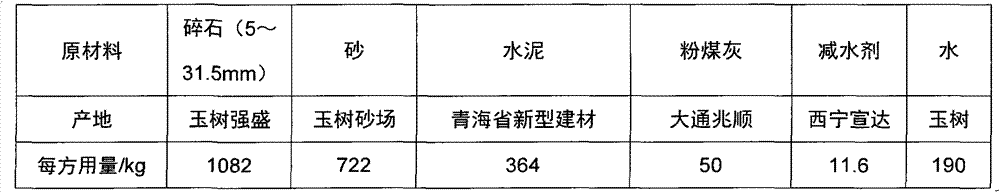

[0012] Taking a mixing plant in Yushu as an example, the raw materials and mix ratios used in the production of C35 concrete are shown in Table 1.

[0013] Table 1 Raw materials and mix ratios used in C35 concrete

[0014]

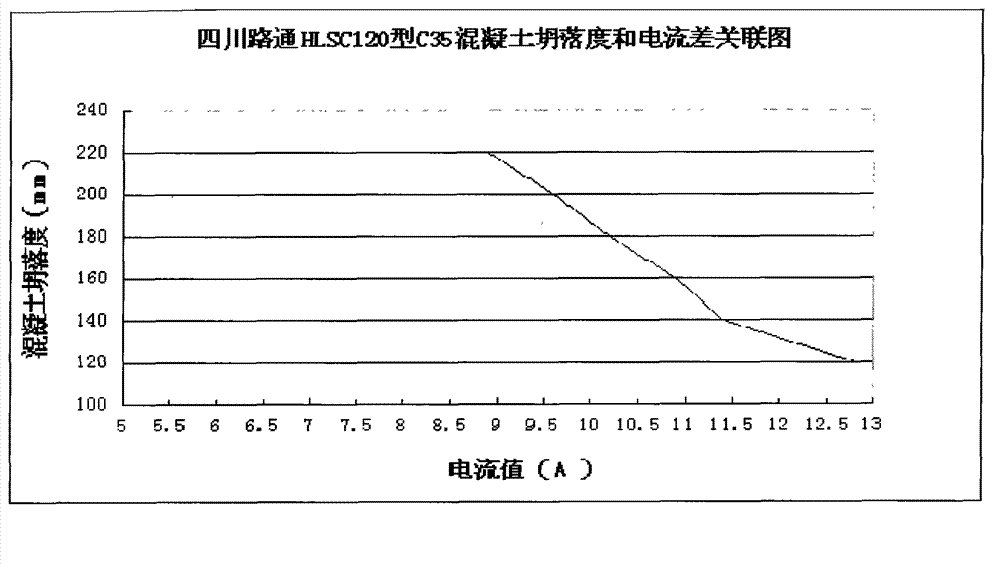

[0015] After testing, when the 1# production line of the mixing station produces C35 concrete with 3 cubic meters per plate, when the slump range is 180±20mm, the meter shows that the current difference changes between 9.7 and 10.7A. figure 1 It is the relationship curve between the C35 concrete slump and the current difference of the mixing equipment. It can be seen that with the increase of the current difference of the mixing equipment, the concrete slump presents a linear decreasing trend. In actual production, the corresponding concrete slump can be inferred by observing the corresponding current difference with reference to this curve. When the inferred slump does not meet the construction requirements, the technicians will make adjustments in tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com