Dent adjusting device of dent splitting machine

A technology of adjusting device and slitting machine, which is applied in the direction of mechanical processing/deformation, etc., can solve the problems of large adjustment and alignment error of indentation line, difficult control of indentation depth, and large volume of the whole machine, so as to achieve easy indentation depth, The crimping process is smooth and the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

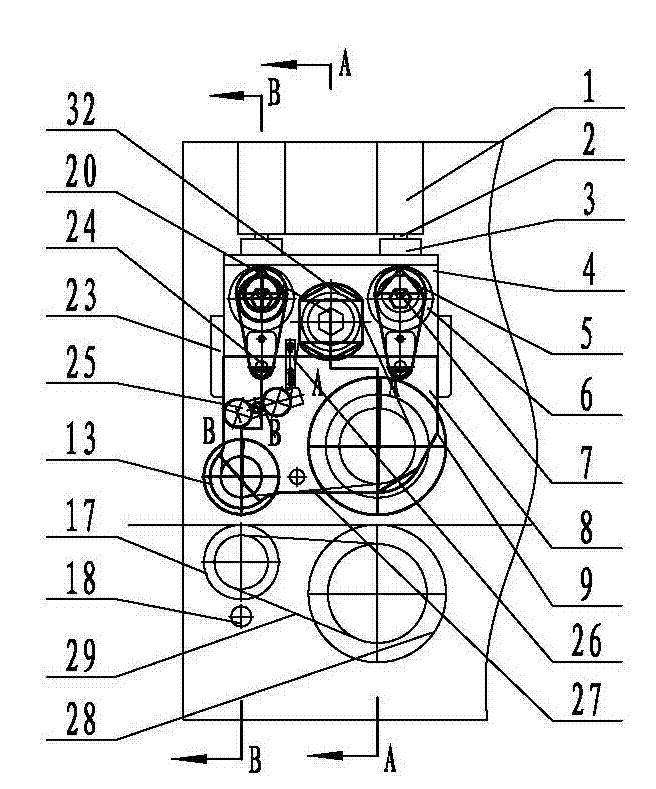

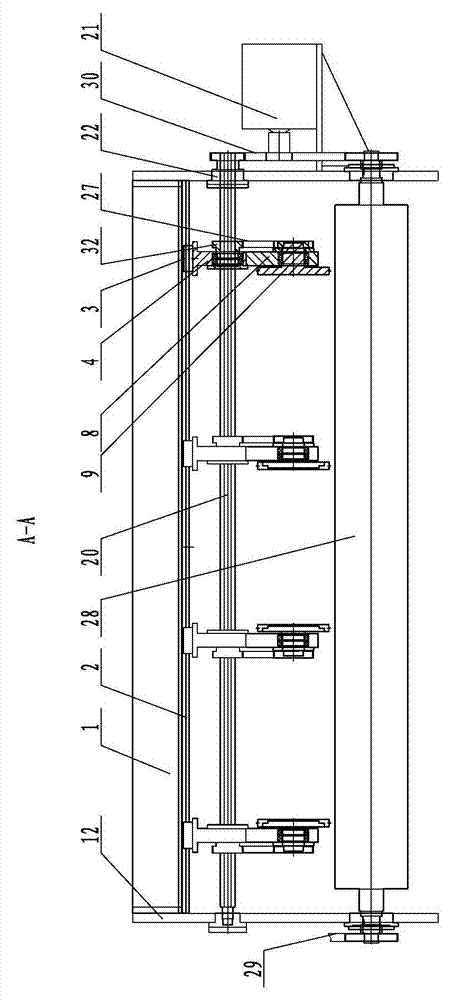

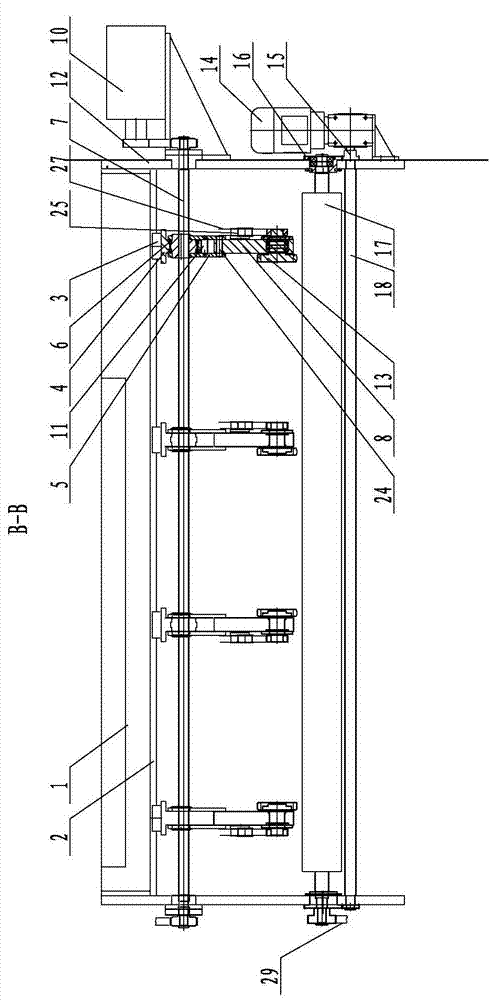

[0019] The first embodiment, combined with Figure 1 to Figure 3 illustrate. For the sake of clarity, figure 1 The wall panel 12 on one side is removed.

[0020] As shown in the figure, the first embodiment is a group of single crimping devices with four sets of crimping parts, as follows figure 2 with image 3 Take the set on the right as an example. The guide rail beam 1 is horizontally fixedly installed between the vertical wall panels 12 on the left and right sides, and the linear guide rail 2 is located below the guide rail beam 1 . A slider 3 is fixed on the upper plane of the fixed plate 4, and the slider 3 is slidingly matched with the linear guide rail 2 in the horizontal direction. The vertical side of the fixed plate perpendicular to the axis of the linear guide rail is parallel to the wall panel 12 . The power driving wheel 32 is installed in the power driving wheel mounting hole on the vertical center line of the vertical side of the fixed plate by a bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com