Magnetic navigation feeding trolley

A feeding trolley and magnetic navigation technology, applied in conveyors, transportation and packaging, non-mechanical conveyors, etc., can solve problems such as long battery life, and achieve the effects of high labor intensity, low production efficiency, and more staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

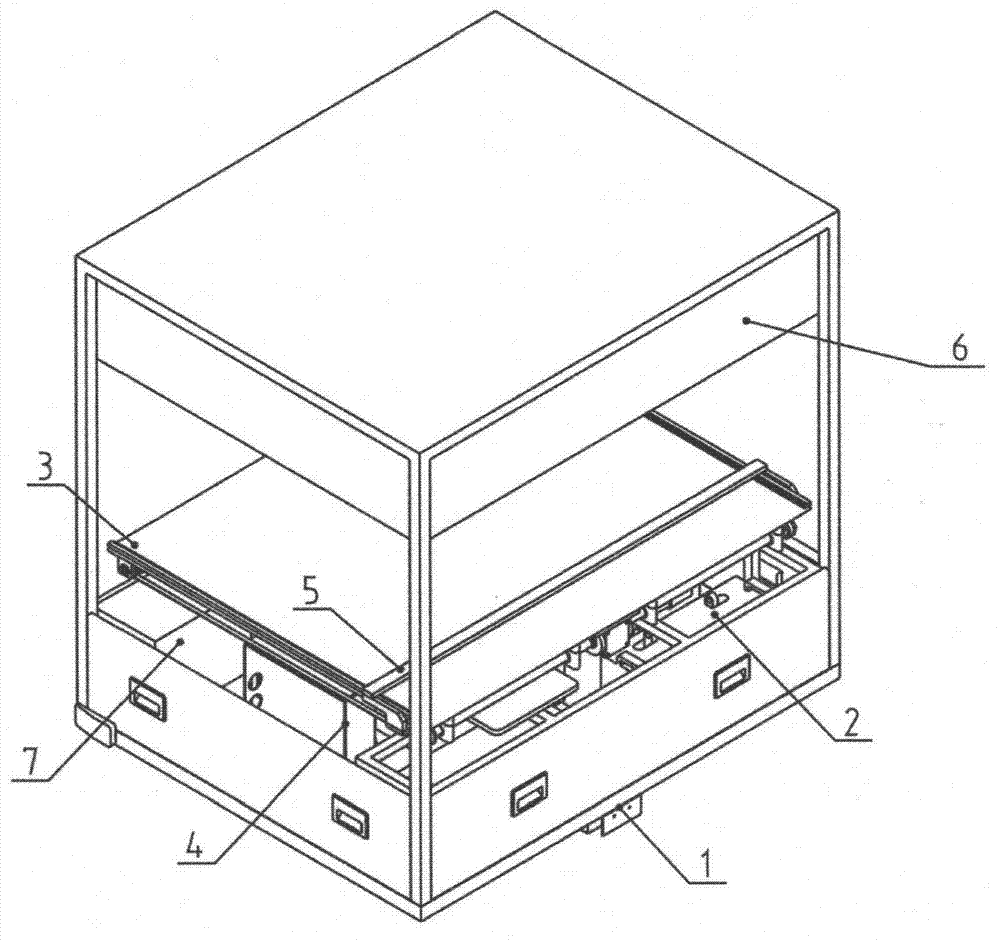

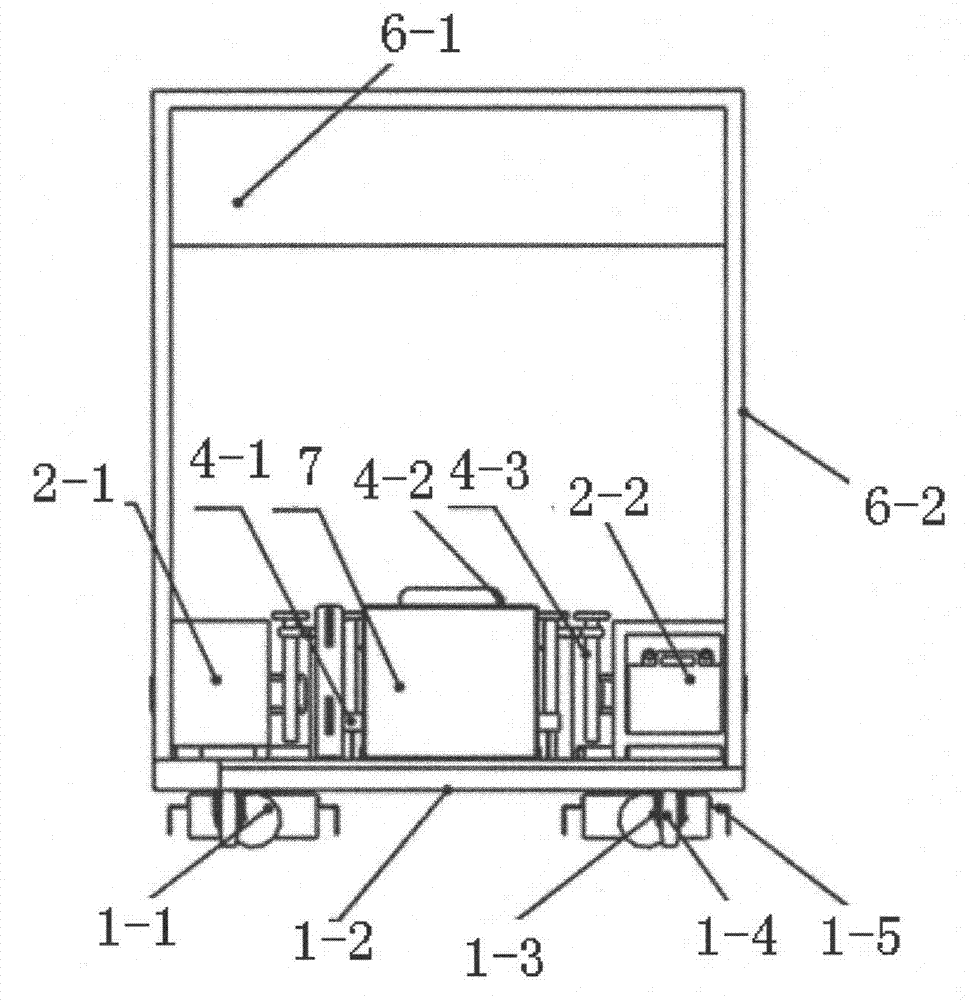

[0044] Such as figure 1 As shown, a magnetic navigation feeding trolley provided by the present invention includes a trolley-driven chassis 1, and the chassis control system controls the trolley-driven chassis 1 to run along a preset path under the guidance of magnets or magnetic strips pre-laid on the ground . The trolley-driven chassis 1 and the chassis control system can refer to existing unmanned guided vehicles guided by magnets or magnetic strips. combine figure 2 , in this embodiment, the trolley drive chassis 1 includes a magnetic navigation drive front wheel 1-1, a chassis assembly 1-2, a magnetic navigation drive rear wheel 1-3, a chassis universal wheel 1-4 that can rotate freely at 360° and Command sensors 1-5 etc. The driving power is the 48V DC power supply provided by the power supply system 2, and the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com