TPV material for automobile interior trim and preparation method thereof

An automobile and pigment yellow technology, applied in the field of automobile interior materials, can solve the problems of poor thermal properties, modulus, strength and thermal mechanical properties, and is not suitable for high-quality requirements, and achieves good retention and excellent thermal properties. Properties and thermomechanical properties, effect of high physico-mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

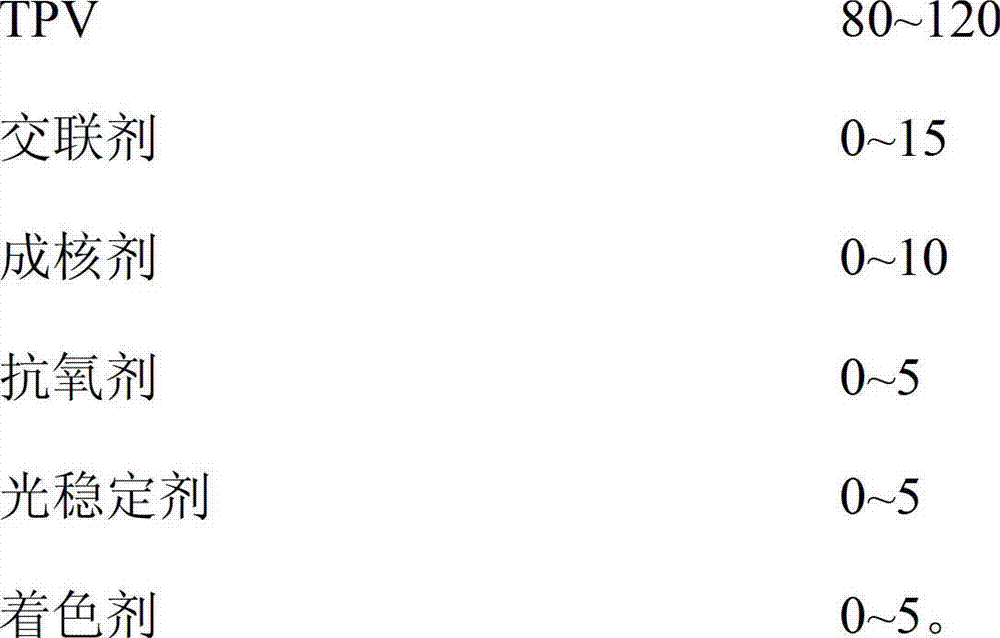

[0046] Table 1 describes the composition of the TPV materials in Examples 1-4 in parts by weight.

[0047] The composition of table 1 embodiment 1-4TPV material

[0048] Example

1

2

3

4

TPV

100

100

100

100

triallyl trimellitate

15

5

5

5

Aluminum tert-butylbenzoate

8

8

4

4

Hindered Phenolic Antioxidants

2

2

2

1

paint

3

3

3

3

[0049] Each component was mixed according to the formula amount of Examples 1-4, and a TPV film was obtained by calendering.

[0050] The TPV film is either not subjected to radiation cross-linking treatment, or is subjected to positive mold molding after radiation cross-linking with 10kGy, 60kGy, 130kGy, or 200kGy. The molding effect, surface pattern, and tensile strength change of the obtained film (compared with the sample without radiation treatment as 100%) were compared, and the results are shown in Tabl...

Embodiment 5

[0055] A TPV material for automobile interior decoration, comprising 100 parts by weight of TPV and 1 part by weight of a crosslinking agent.

[0056] The preparation method of above-mentioned TPV material is:

[0057] (1) Obtain TPV film by calendering;

[0058] (2) Carry out surface embossing and surface coating treatment processes on the TPV film obtained in step (1), and then use electron beams to perform radiation crosslinking. The radiation dose of the electron beams is 200 kGy to obtain the TPV material for automotive interior decoration.

Embodiment 6

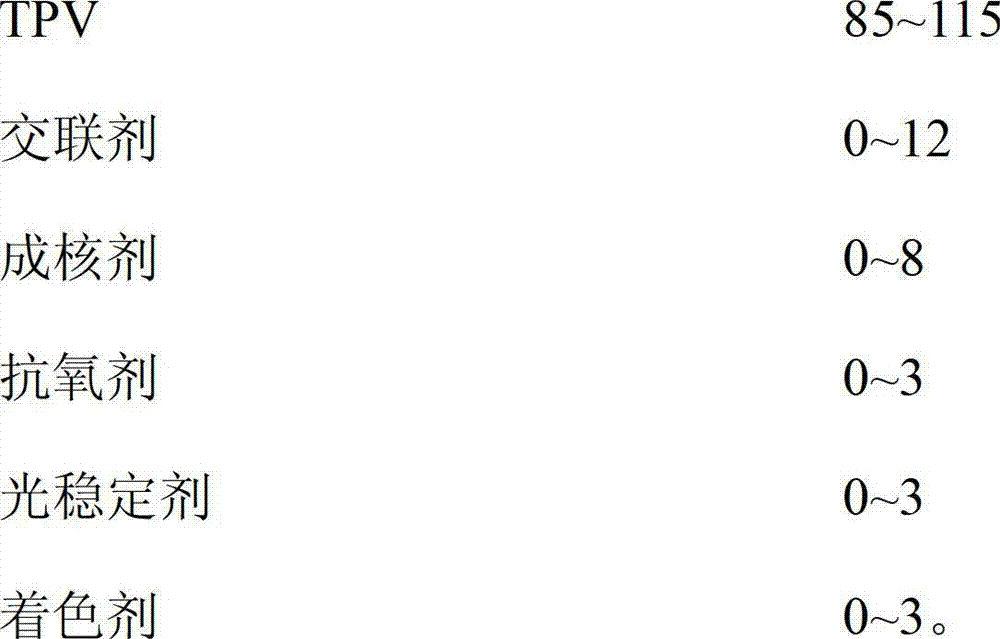

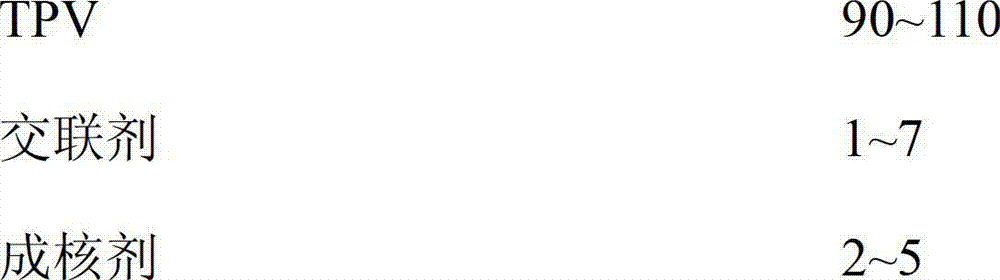

[0060] A kind of TPV material for automotive interior, comprising by weight parts:

[0061]

[0062] The preparation method of above-mentioned TPV material is:

[0063] (1) Obtain TPV film by calendering;

[0064] (2) Carry out surface embossing and surface coating treatment processes on the TPV film obtained in step (1), and then use electron beams to carry out radiation crosslinking. The radiation dose of electron beams is 1 kGy to obtain the TPV material for automotive interiors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap