Epoxy resin-reinforced polystyrene halogen-free flame-retardant material and preparation method thereof

A technology of polystyrene and epoxy resin, which is applied in the field of polymer materials, can solve the problems of decreased tensile strength, high performance, and decreased rigidity of polystyrene, so as to achieve good strength improvement, comprehensive performance improvement, and good flame retardant effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

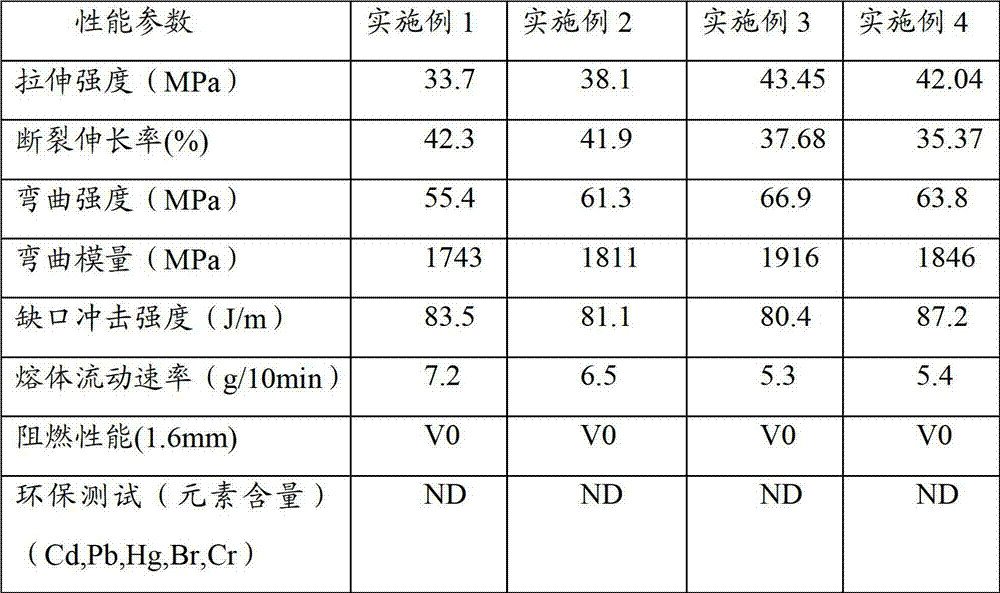

Examples

Embodiment 1

[0046] The epoxy resin reinforced polystyrene flame retardant material provided in Example 1 contains the following ingredients in parts by weight:

[0047] General-purpose polystyrene (GPPS) 76;

[0048] Elastomer (SBS) 10;

[0049] Epoxy resin (EP) 3;

[0050] 4,4′-Diaminodiphenylmethane (DDM) 1;

[0051] White oil 0.1;

[0052]Coated red phosphorus flame retardant 5;

[0053] Diphenyl phosphate 4;

[0054] Antioxidant 168 0.4;

[0055] Dispersant EBS 0.5.

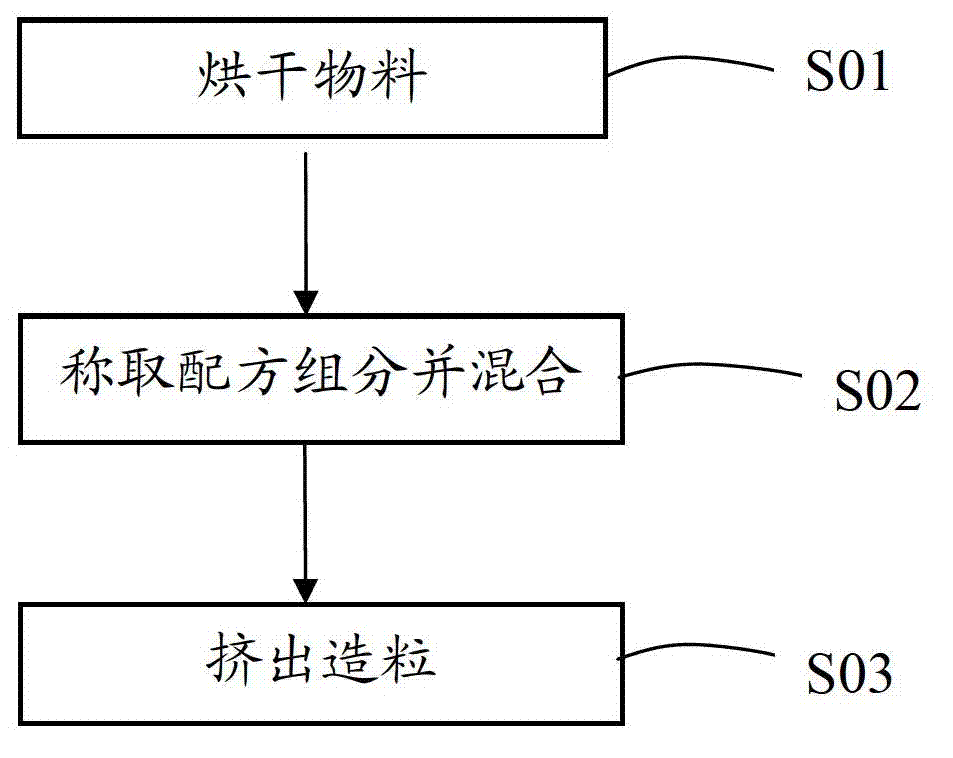

[0056] The preparation method of the epoxy resin reinforced polystyrene flame retardant material that embodiment 1 provides comprises the steps:

[0057] Step 1, drying: polystyrene and styrene-butadiene-styrene block copolymer were dried in an oven at 80°C for 6 hours, and epoxy resin was dried in an oven at 70°C for 4 hours;

[0058] Step 2, weighing and mixing the formula components: weigh the above formula materials according to the above weight fractions, and then mix them in a high-speed mixer for 5 minutes...

Embodiment 2

[0062] The epoxy resin reinforced polystyrene flame retardant material provided in Example 2 contains the following ingredients in parts by weight:

[0063] General-purpose polystyrene (GPPS) 75;

[0064] Elastomer (SBS) 10;

[0065] Epoxy resin (EP) 4;

[0066] DDM 1;

[0067] White oil 0.2;

[0068] Coated red phosphorus flame retardant 5;

[0069] Diphenyl phosphate 4;

[0070] Antioxidant 168 0.5;

[0071] Dispersant EBS 0.3.

[0072] The preparation method of the epoxy resin reinforced polystyrene flame retardant material that embodiment 2 provides comprises the steps:

[0073] Step 1, drying: polystyrene and styrene-butadiene-styrene block copolymer were dried in an oven at 80°C for 6 hours, and epoxy resin was dried in an oven at 70°C for 4 hours;

[0074] Step 2, weighing and mixing the formula components: weigh the above formula materials according to the above weight fractions, and mix them in a high-speed mixer for 7 minutes;

[0075] Step 3. Extrusion and ...

Embodiment 3

[0078] The epoxy resin reinforced polystyrene flame retardant material provided in Example 3 contains the following ingredients in parts by weight:

[0079] General-purpose polystyrene (GPPS) 74;

[0080] Elastomer (SBS) 10;

[0081] Epoxy resin (EP) 5;

[0082] DDM 1;

[0083] White oil 0.3;

[0084] Coated red phosphorus flame retardant 5;

[0085] Diphenyl phosphate 4;

[0086] Antioxidant 168 0.4;

[0087] Dispersant EBS 0.2.

[0088] The preparation method of the epoxy resin reinforced polystyrene flame retardant material provided by embodiment 3 comprises steps:

[0089] Step 1, drying: polystyrene and styrene-butadiene-styrene block copolymer were dried in an oven at 80°C for 6 hours, and epoxy resin was dried in an oven at 70°C for 4 hours;

[0090] Step 2, weighing and mixing the formula components: weigh the above formula materials according to the above weight fractions, and mix them in a high-speed mixer for 10 minutes;

[0091] Step 3. Extrusion and granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com