Anti-static water-based ink and preparation method thereof

A water-based ink, anti-static technology, applied in the field of ink, can solve the problems of accelerated ink leakage, ink adhesion, decreased brightness, poor printing effect, etc., and achieves the effect of saving manufacturing cost, low production cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

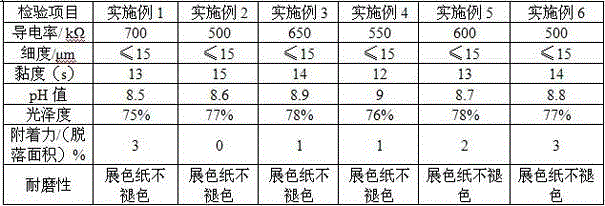

Examples

Embodiment 1

[0054] An antistatic water-based ink, which is composed of the following raw materials in parts by weight: an aqueous solution of 35 parts of conductive carbon black, 40 parts of acrylic resin, 4 parts of ethylene-vinyl acetate copolymer, 1.5 parts of anti-scratch agent, and 1 part of acrylic amine resin , 0.6 parts of defoamer, 35 parts of water.

[0055] The preparation method of the antistatic water-based ink of the present embodiment comprises the following preparation steps: a, stirring the conductive carbon black, acrylic resin, defoamer and water according to the above weight parts to prepare the color paste, and grinding the color paste to The fineness is below 15 microns; b, the color paste after grinding in step a is tested for abrasion resistance and scratch resistance; c, the ethylene-vinyl acetate copolymer, anti-scratch agent and acrylic amine resin of the above-mentioned parts by weight The aqueous solution is added to the qualified color paste detected in step ...

Embodiment 2

[0057] An antistatic water-based ink, which is composed of the following raw materials in parts by weight: an aqueous solution of 26 parts of conductive carbon black, 32 parts of acrylic resin, 1 part of ethylene-vinyl acetate copolymer, 0.6 part of anti-scratch agent, and 0.2 part of acrylic amine resin , 0.1 part of defoamer, 28 parts of water.

[0058] The preparation method of the antistatic water-based ink of the present embodiment comprises the following preparation steps: a, stirring the conductive carbon black, acrylic resin, defoamer and water according to the above weight parts to prepare the color paste, and grinding the color paste to The fineness is below 15 microns; b, the color paste after grinding in step a is tested for abrasion resistance and scratch resistance; c, the ethylene-vinyl acetate copolymer, anti-scratch agent and acrylic amine resin of the above-mentioned parts by weight The aqueous solution is added to the qualified color paste detected in step b...

Embodiment 3

[0060] An antistatic water-based ink, which is composed of the following raw materials in parts by weight: an aqueous solution of 28 parts of conductive carbon black, 33 parts of acrylic resin, 1 part of ethylene-vinyl acetate copolymer, 0.8 part of anti-scratch agent, and 0.3 part of acrylic amine resin , 0.2 parts of defoamer, 30 parts of water.

[0061] The preparation method of the antistatic water-based ink of the present embodiment comprises the following preparation steps: a, stirring the conductive carbon black, acrylic resin, defoamer and water according to the above weight parts to prepare the color paste, and grinding the color paste to The fineness is below 15 microns; b, the color paste after grinding in step a is tested for abrasion resistance and scratch resistance; c, the ethylene-vinyl acetate copolymer, anti-scratch agent and acrylic amine resin of the above-mentioned parts by weight The aqueous solution is added to the qualified color paste detected in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap