An economical heat-resistant austenitic stainless steel

An economical technology of austenitic stainless steel, applied in the field of stainless steel, can solve the problem of high manufacturing cost and achieve the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

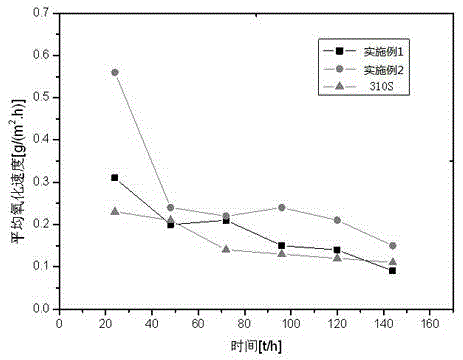

Embodiment 1

[0034] The economical heat-resistant austenitic stainless steel of this embodiment contains the following components in weight percentage: Cr 20.91%, Ni 11.0%, Si 1.59%, N 0.15%, C 0.063%, RE 0.04%, Nb 0.02%, Mn 0.68 %, Cu 0.12%, P 0.023%, S 0.001%, and the balance is Fe.

Embodiment 2

[0036] The economical heat-resistant austenitic stainless steel of this embodiment contains the following components in weight percentage: Cr 20.85%, Ni 10.9%, Si 1.62%, N 0.16%, C 0.092%, RE 0.04%, Nb 0.08%, Mn 0.67 %, Cu 0.11%, P 0.019%, S 0.001%, and the balance is Fe.

Embodiment 3- Embodiment 11

[0038] Refer to Table 1 for the components of the economical heat-resistant austenitic stainless steel in Example 3-Example 11.

[0039] Table 1: Composition list of the economical heat-resistant austenitic stainless steels of Example 3-Example 11.

[0040] components Cr / % Ni / % Si / % N / % C / % RE / % Nb / % Mn / % Cu / % P / % S / % Fe / % Example 3 20 10 1.5 0.14 0.04 0.03 0.01 0.3 0.05 0.020 0.001 margin Example 4 22 12 2.0 0.22 0.12 0.08 0.15 0.8 0.18 0.020 0.001 margin Example 5 21 11 1.7 0.20 0.08 0.05 0.10 0.5 0.1 0.020 0.001 margin Example 6 21 10 1.5 0.14 0.04 0.03 0.01 0.3 0.1 0.020 0.001 margin Example 7 21 12 2.0 0.22 0.12 0.08 0.15 0.8 0.15 0.020 0.001 margin Example 8 20 12 2.0 0.22 0.12 0.08 0.15 0.8 0.12 0.020 0.001 margin Example 9 20 11 1.7 0.20 0.08 0.05 0.10 0.5 0.08 0.020 0.001 margin Example 10 22 10 1.5 0.14 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com