Spinning solution, nuclear shell nanofiber as well as preparation method and application thereof

A technology of nanofibers and spinning solutions, which can be used in rayon manufacturing, fiber chemical characteristics, textiles and papermaking, etc., and can solve problems such as high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

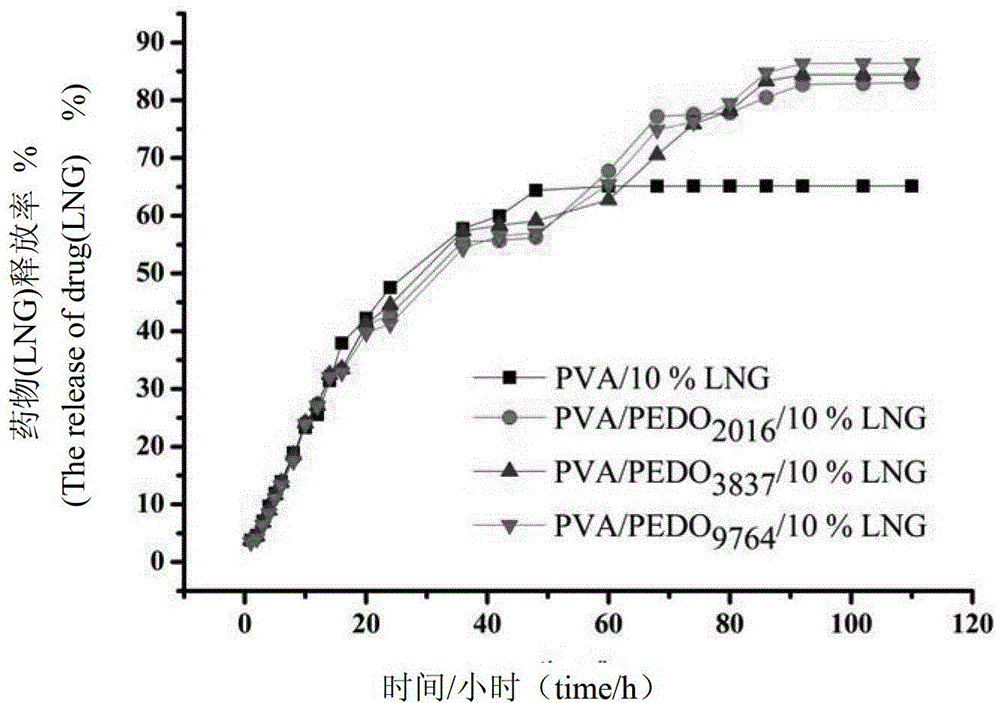

Embodiment 1

[0102] Weigh a certain amount of polyvinyl alcohol (PVA, average polymerization degree 1700, alcoholysis degree 88%) according to the formula and dissolve it in a certain volume of distilled water. The concentration of PVA is 4%wt / v (ie 0.04g / ml), Heat and stir at 80°C for 12 hours, while weighing a certain amount of polyethylene glycol-b-poly(p-dioxanone) (PEG-b-PPDO, or PEDO) of three different molecular weights. Its molecular structure is diblock. The weight average molecular weights are 9764, 3837 and 2716, respectively. The mass ratios of hydrophilic block PEG and lipophilic block PPDO are respectively 1:4, 1:0.9 and 1:0.7) respectively dissolved in a certain volume of distilled water to obtain three A PEDO solution and the concentration of the three PEDO solutions are 1%wt / v (ie 0.01g / ml), heated and stirred at 30 ℃ for 2h, and then the above PVA solution and each PEDO solution (ie PVA solution and three Any one of the PEDO solutions in the PEDO solution) are mixed to obt...

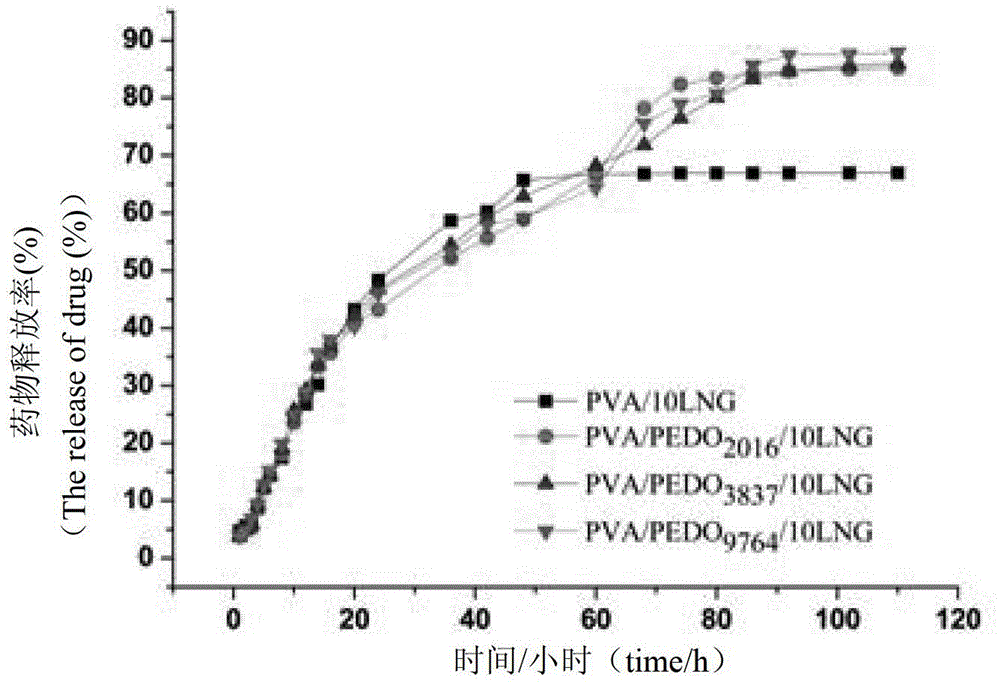

Embodiment 2

[0104] Weigh a certain amount of polyvinyl alcohol (PVA, average polymerization degree 1700, alcoholysis degree 88%) according to the formula and dissolve it in a certain volume of distilled water. The concentration of PVA is 4%wt / v (ie 0.04g / ml), Heat and stir at 80℃ for 12h, and weigh a certain amount of polyethylene glycol-b-poly(p-dioxanone) (PEG-b-PPDO, PEDO) with three different molecular structures. The weight-average molecular weights of tri-block and multi-block are 3837, 5670 and 15000, respectively. The mass ratios of hydrophilic block PEG and lipophilic block PPDO are 1:0.9, 1:1.8 and 1:6.5) respectively. A certain volume of distilled water in order to obtain three PEDO solutions and the concentration of the three PEDO solutions is 5%wt / v (ie 0.05g / ml), heated and stirred at 30℃ for 2h, and then the above PVA solution and each PEDO solution (That is, the PVA solution and any one of the three PEDO solutions) are mixed to obtain three spinning solutions respectively. ...

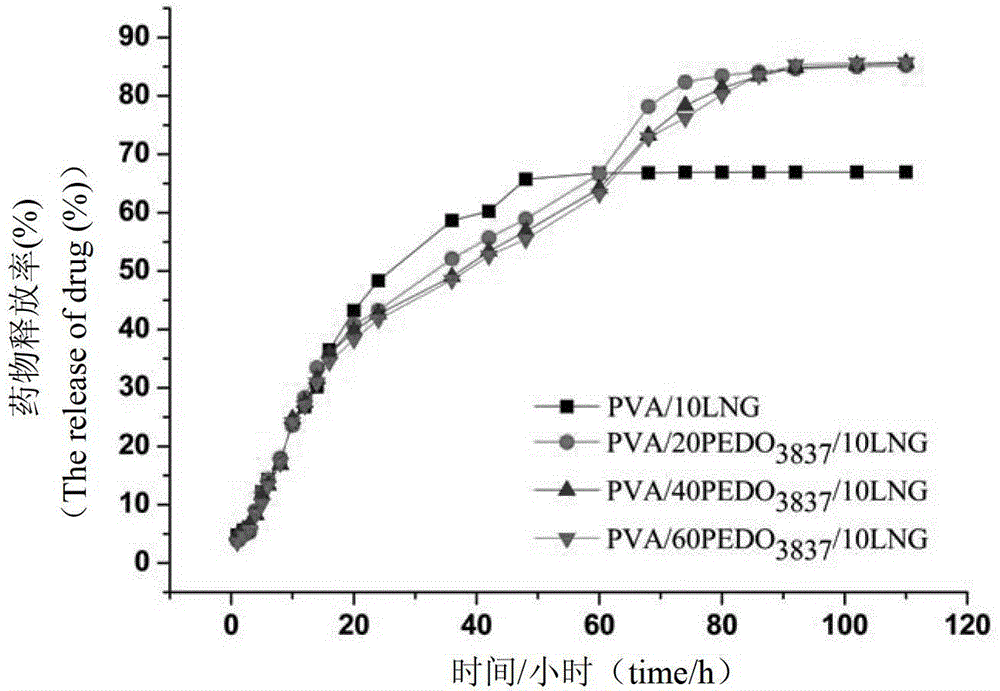

Embodiment 3

[0106] Weigh a certain amount of polyvinyl alcohol (PVA, average polymerization degree 1700, alcoholysis degree 66%) according to the formula and dissolve it in a certain volume of distilled water. The concentration of PVA is 4%wt / v (ie 0.04g / ml), Heat and stir at 80°C for 12 hours, while weighing a certain amount of polyethylene glycol-b-poly(p-dioxanone) (PEG-b-PPDO, or PEDO) of three different molecular weights. Its molecular structure is diblock. The weight-average molecular weights are 9764, 3837 and 2716, respectively. The mass ratios of hydrophilic block PEG and lipophilic block PPDO are 1:3.8, 1:0.9 and 1:0.35), respectively, dissolved in a certain volume of distilled water to obtain three A PEDO solution and the concentration of the three PEDO solutions are all 10%wt / v (ie 0.1g / ml), heated and stirred at 30 ℃ for 2h, and then the above PVA solution and each PEDO solution (ie PVA solution and three Any one of the PEDO solutions in the PEDO solution) are mixed to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com