Inside-support-free ring-shaped enclosure structure and manufacturing method thereof

An enclosure structure and ring-shaped technology, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of settlement and displacement of buildings and structures, high cost of measures, and long production cycle, so as to reduce engineering costs, make structures easy, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A ring-shaped enclosure structure without inner support

[0036] A ring-shaped enclosure structure without internal support adopts an enclosure pile and a ring beam support system without internal support, including enclosure piles and closed ring beams, and is characterized in that:

[0037] The retaining pile is a bored cast-in-place pile with a diameter of 800mm, and the depth of the pile end embedded in the weathered rock layer is not less than 500mm;

[0038] The closed ring beam is arranged in the form of an inscribed circle of the enclosure pile, including a crown beam set on the top of the enclosure pile and a waist beam set in the middle of the enclosure pile, wherein the cross-sectional area of the crown beam is 1000x800mm, and the cross-sectional area of the waist beam The area is 1000x700mm;

[0039] Wherein: the depth of the bored cast-in-place pile embedded in the weathered lamprophyre or marble rock layer is greater than or equal to 1000mm; the steel...

Embodiment 2

[0041] A method of manufacturing a ring-shaped enclosure structure without inner support

[0042] A method for manufacturing an annular enclosure structure without internal support, characterized in that it comprises the following steps:

[0043] a. According to the geological survey data, use the PKPM production calculation software developed by the China Academy of Building Research and the Tongji Venus deep foundation pit support structure design analysis calculation software FRWS2006 to design the foundation pit enclosure, and determine the number, length and size of the bored piles position, the elevation of the closed ring beam, and the closed ring beam is set in the form of an inscribed circle around the retaining pile;

[0044] b. The rotary drilling rig of German Bauer company is used in the production of bored piles, so that the depth of anchoring the lower end of bored piles into the weathered rock is not less than 500mm; For a crown beam, after the first soil laye...

Embodiment 3

[0047] A method for manufacturing a ring-shaped enclosure swirl pool structure without inner support

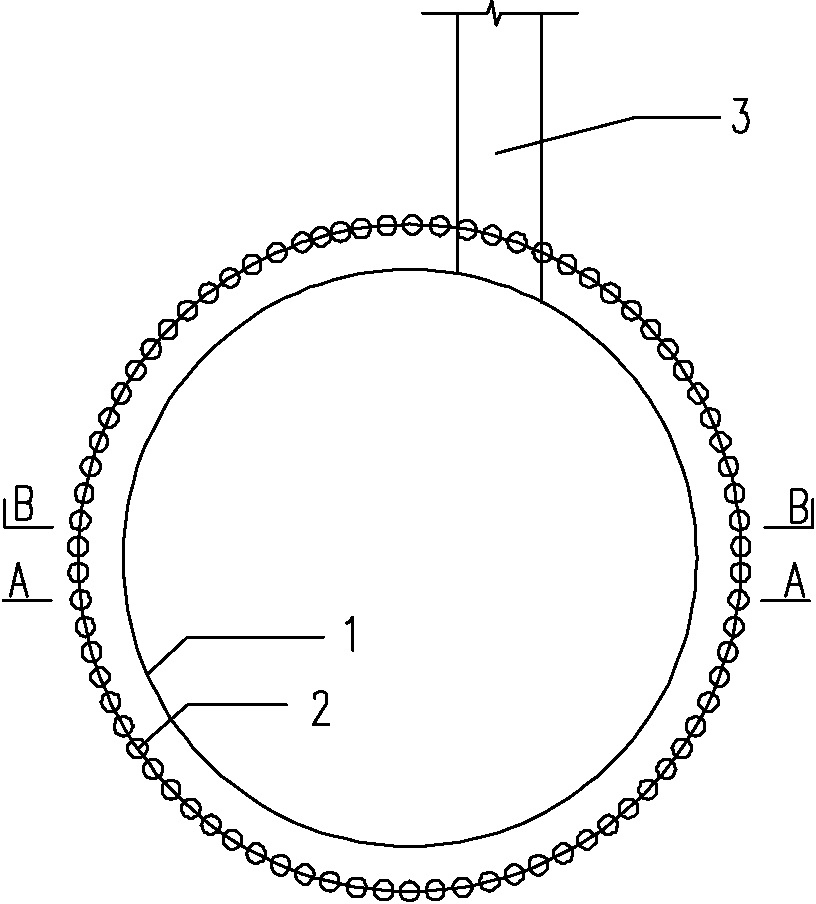

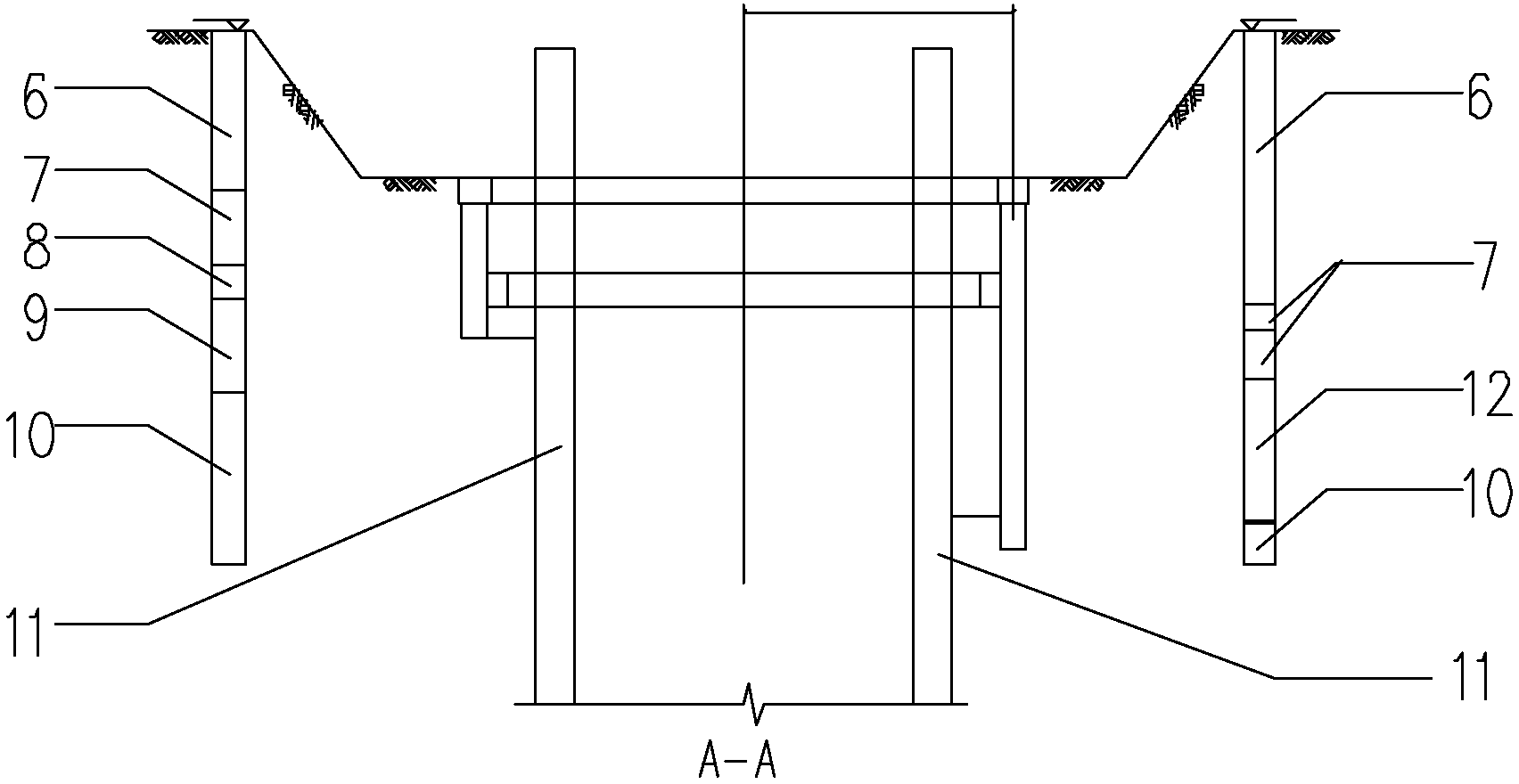

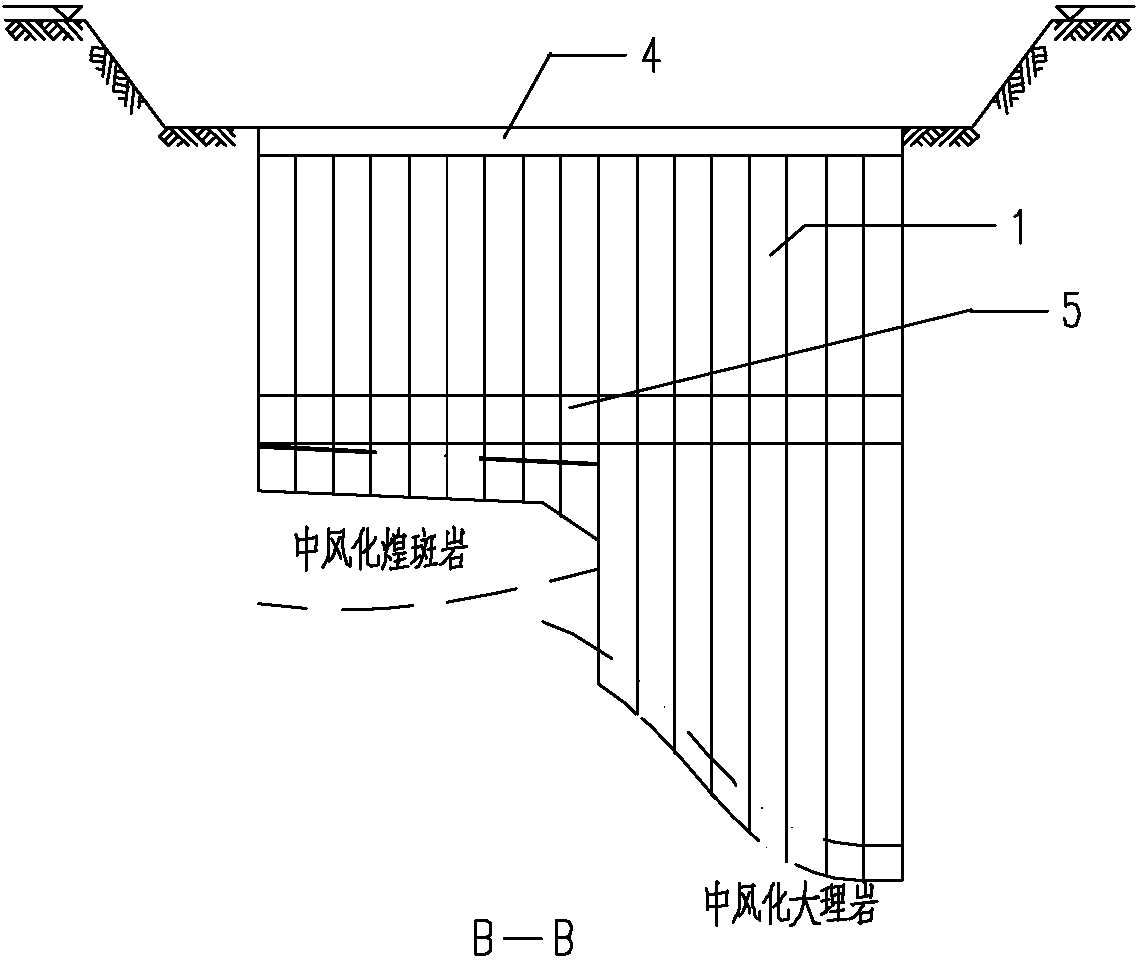

[0048] see now Figure 1 ~ Figure 3 , figure 1 It is a plan view of the foundation pit support of the swirl pool according to the embodiment of the present invention, figure 2 for figure 1 The sectional view of A-A in, image 3 for figure 1 Sectional view of B-B in middle. As shown in the figure, the

[0049] The hot-rolled swirling pool of the embodiment of the present invention adopts the following steps in actual production:

[0050] The hot-rolled swirling pool of the embodiment of the present invention is located on the south side of the main factory building, 6.4m away from the built main power room, and 2.35m away from the main factory building. m. The upper part of the area it belongs to is backfill, and the lower part is rock foundation, and the bedrock is mainly slate, lamprophyre and marble.

[0051] The field investigation data are as follows:

[0052] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap