Prefabricated recycled concrete shear wall with energy dissipation connector and fabrication method

A technology of recycled concrete and shear walls, applied to walls, building components, buildings, etc., can solve the problems of ecological environment deterioration and waste concrete disposal difficulties, and achieve the goals of protecting the living environment, ensuring sustainable development, and enhancing energy consumption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

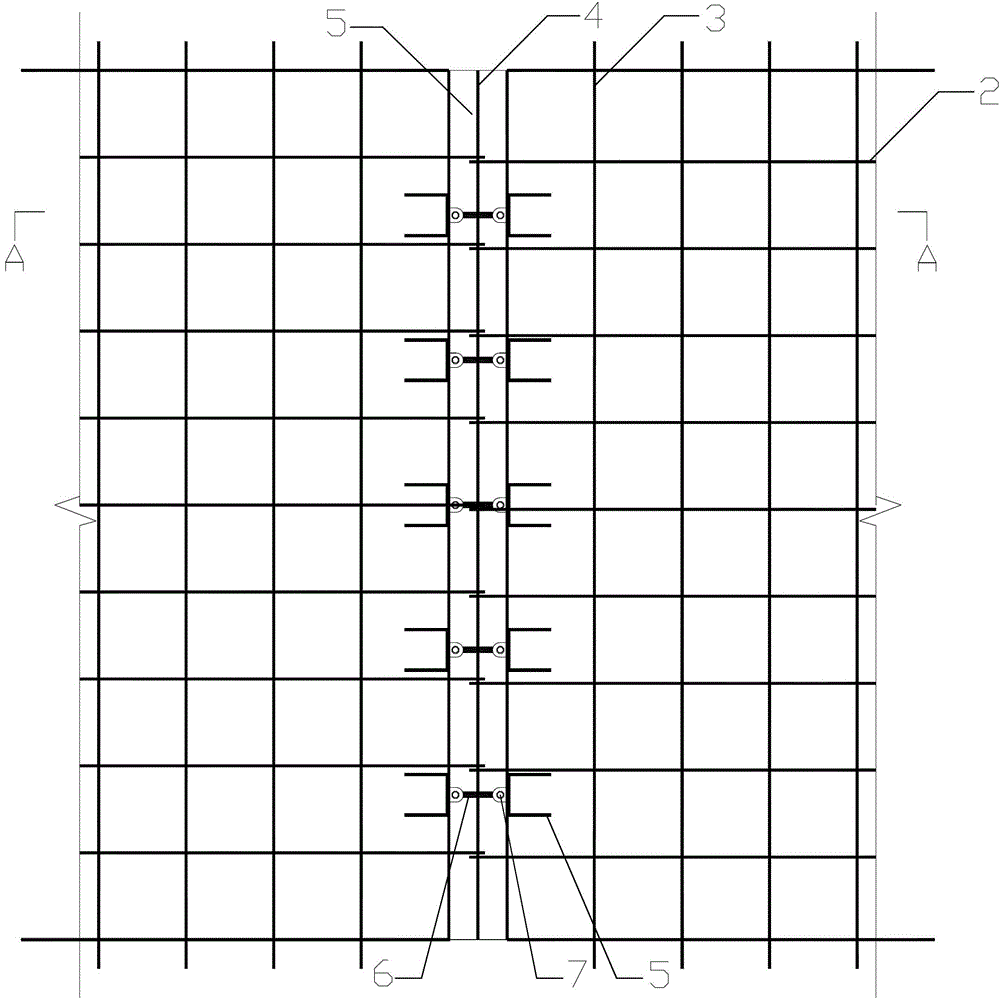

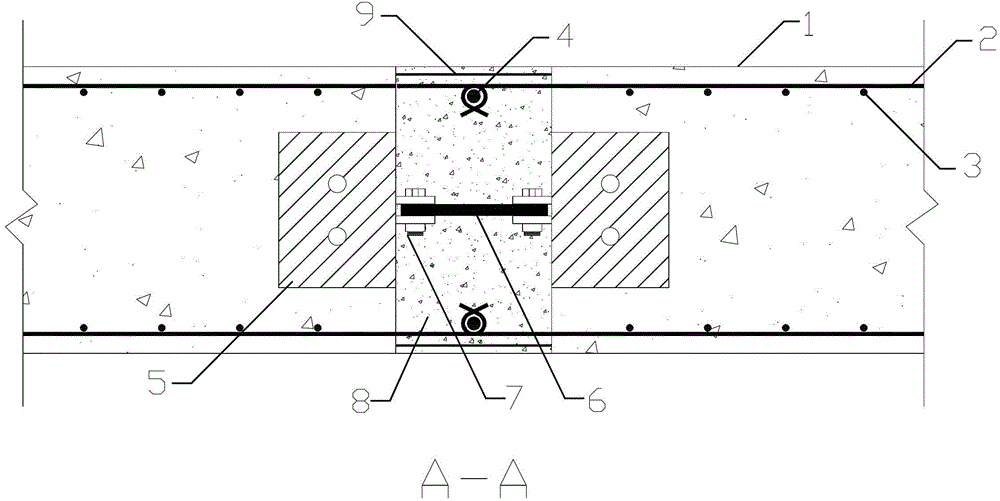

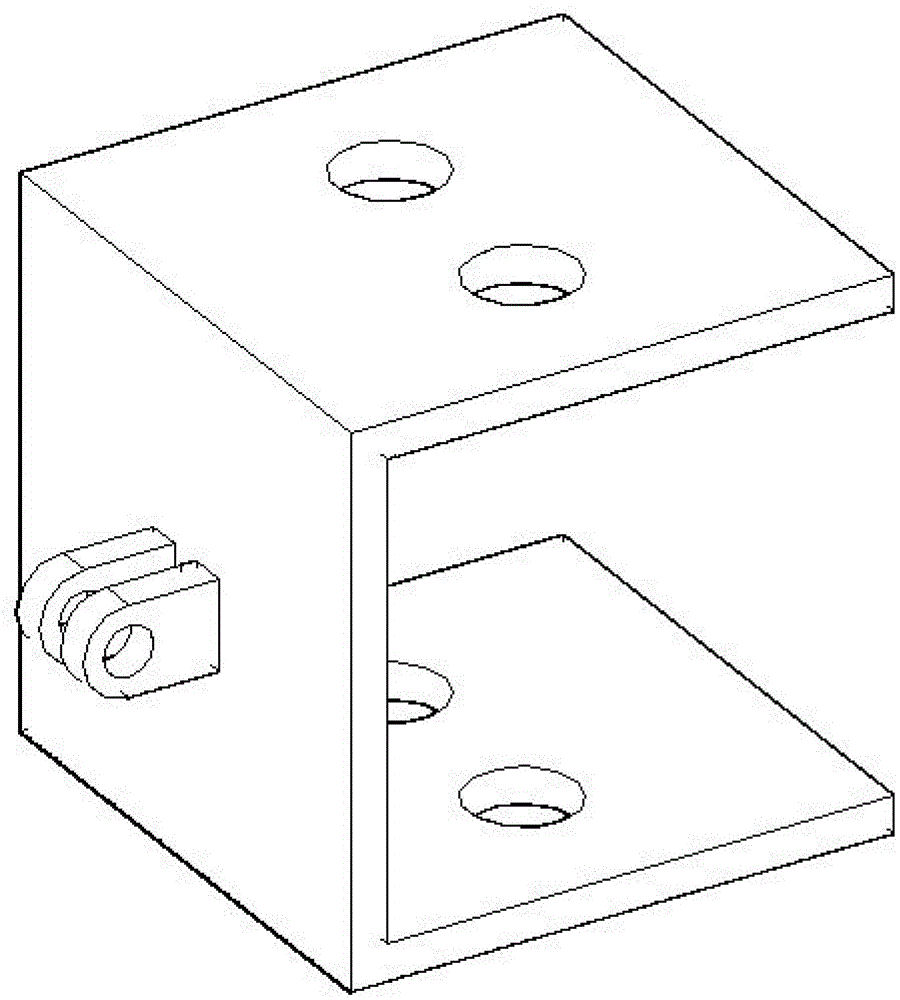

[0033] Example: such as Figure 1-3 as shown, figure 1 It is a schematic diagram of the prefabricated recycled concrete band energy dissipation connecting key shear wall of the present invention, figure 2 It is the A-A cross-sectional schematic diagram of the prefabricated recycled concrete band energy-dissipating connection key shear wall of the present invention, image 3 It is a three-dimensional schematic diagram of a U-shaped steel channel of the present invention.

[0034] Prefabricated recycled concrete shear wall with energy-dissipating connection key method, the method includes the following steps: place two prefabricated recycled concrete shear wall panels 1 according to the design position, connect U-shaped steel channels on both sides with steel rods 6 and use bolts Fix, overlap the steel bars 2 protruding from the side edge of the wallboard, insert the longitudinal long steel bars 4 for binding, arrange dense steel wire mesh 9, and then formwork and pour low-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com