Variable compression ratio device with connecting rod journals and eccentric sleeves

A technology of connecting rod journal and eccentric sleeve, which is applied in the field of automobile, can solve the problems of heavy structure, low reliability and uneven force of the fitting eccentric sleeve, so as to strengthen the strength, increase the self-locking safety factor, and improve the strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

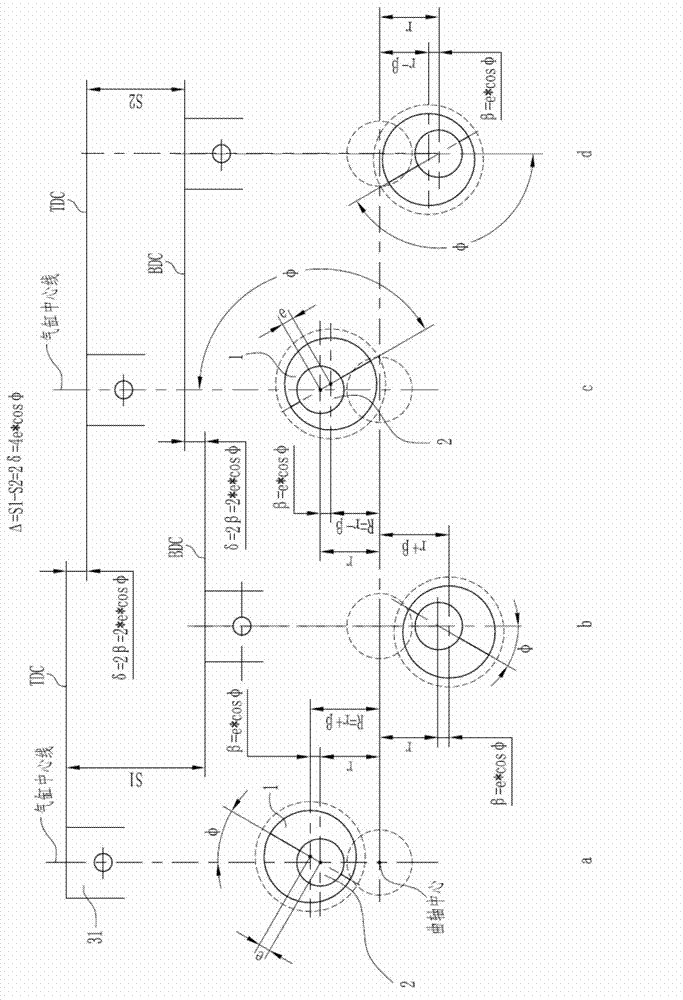

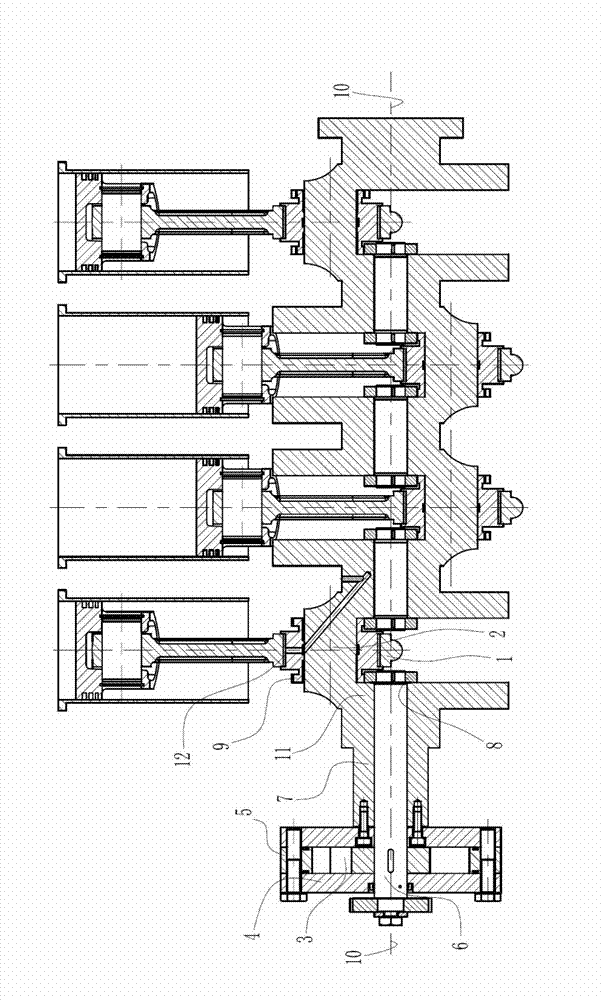

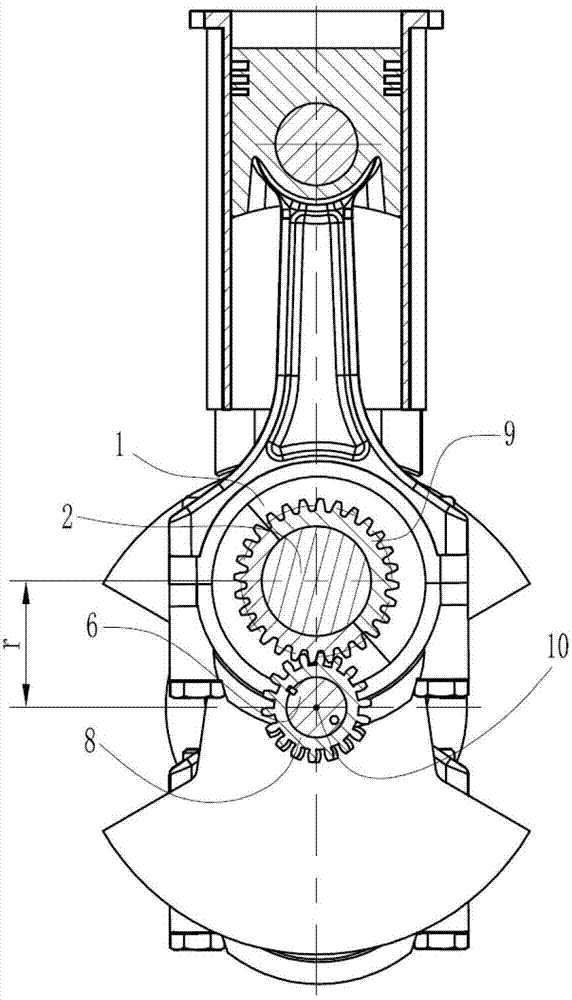

[0070] See first Image 6 The transmission mechanism diagram of the variable compression ratio device of the eccentric sleeve of the connecting rod journal. The connecting rod journal eccentric sleeve variable compression ratio device shown in the figure is installed on the engine, which includes: crankshaft, piston connecting rod assembly, eccentric shaft sleeve assembly, transmission shaft and gear assembly, and driver assembly.

[0071] The crankshaft is a disk-shaped crankshaft, which is formed by combining a traditional engine main journal and a crank arm. The second disc-shaped main journal 18 and the crankshaft rear end journal 23, they follow the crankshaft front-end journal 7, the first disc-shaped main journal 17, a connecting rod journal 2, and a second disc-shaped main journal 18 from front to back. , a connecting rod journal 2, a second disc-shaped main journal 18 ... crankshaft rear end journal 23 are sequentially connected together. The number of the connectin...

Embodiment 2

[0078] The structure of the second embodiment is basically the same as that of the first embodiment, except that the eccentric sleeve 1 is an integral structure, and the crankshaft is a combined structure, that is, the crankshaft front journal 7, the first disc-shaped main journal 17 , a plurality of connecting rod journals 2, a plurality of second disc-shaped main journals 18 and crankshaft rear end journal 23 are all independent members, and they are assembled into a crankshaft after processing respectively. The integral eccentric sleeve 1 has improved strength, uniform stress, and improved reliability. The combined crankshaft is to facilitate the assembly of the integral eccentric sleeve 1 .

[0079] The present invention can be used not only for single-cylinder engines, but also for multi-cylinder engines such as 2-cylinders, 3-cylinders and even 8-cylinders; the present invention is not only suitable for in-line engines, but also V-type, W-type, star-shaped and opposed A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com