Uniformly light-emitting reflective backlight source

A reflective, backlight technology, applied in the field of backlight structure improvement, can solve the problems of large power consumption, uneven light output, and high cost of the backlight, and achieve the effects of reducing product thickness, uniform light output, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

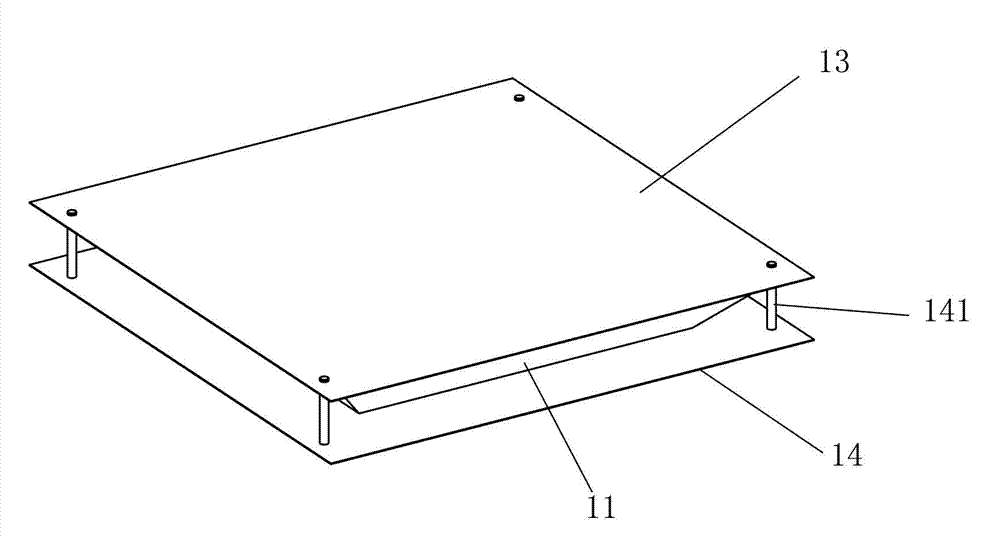

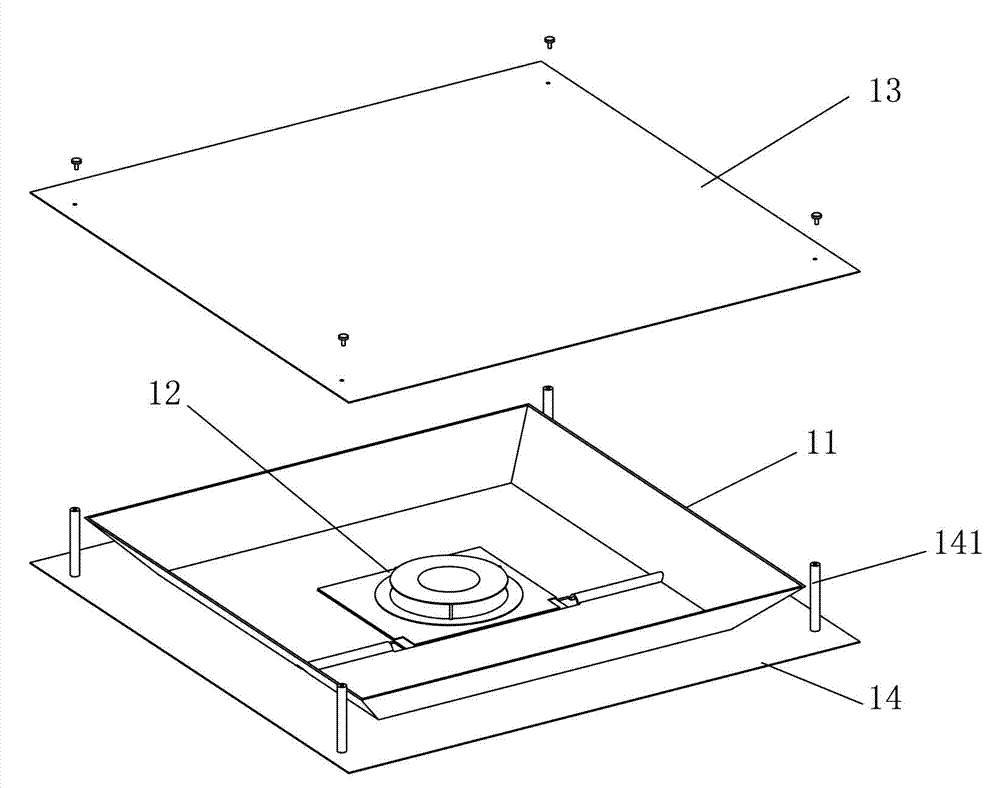

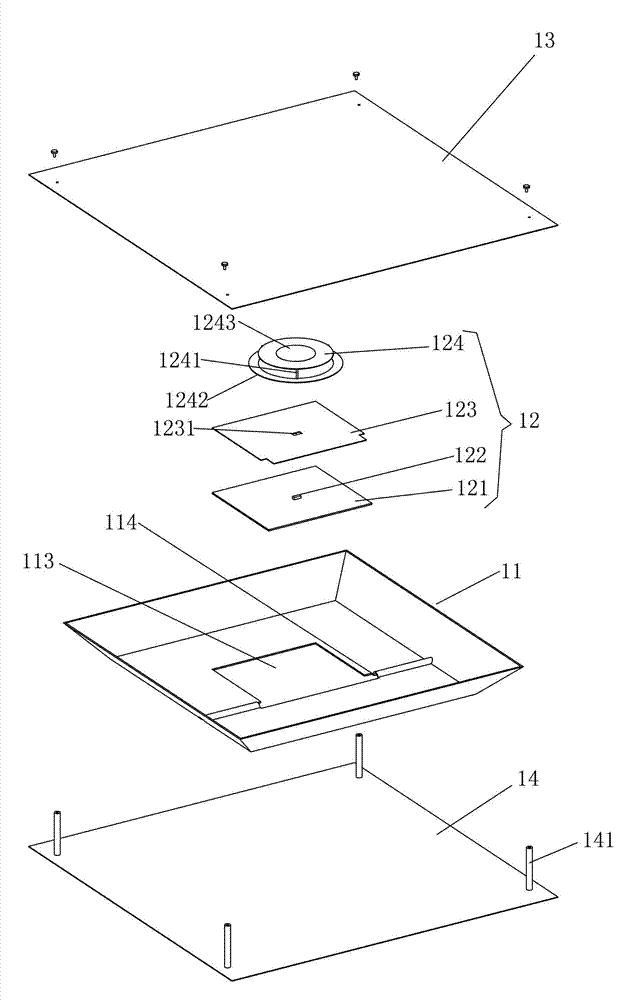

[0021] refer to Figure 1 to Figure 7 As shown in the figure, the present invention includes at least one lighting unit 1, each lighting unit 1 includes a lampshade 11, the center of the lampshade 11 is provided with an LED light source 12, the cover opening of the lampshade 11 is provided with a light diffusion plate 13, and the fixing of the bottom of the lampshade 11 The bottom plate 14 ; the light diffusing plate 13 and the fixed bottom plate 14 are connected by studs 141 .

[0022] The LED light source 12 includes an LED substrate 121, an LED wick 122 is arranged on the LED substrate 121, and a layer of reflective base plate 123 is arranged on the peripheral area of the LED wick 122 on the upper surface of the LED substrate 121, that is, the reflective base plate 123 is provided with T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com