OBS (optical back scattering) working state detector

A technology of working status and detectors, which is applied in the direction of measuring devices, scientific instruments, suspension and porous material analysis, etc., can solve the problems of data interruption, affecting the quality of results, and the inability of operators to know the working status, etc., to achieve strong anti-interference ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

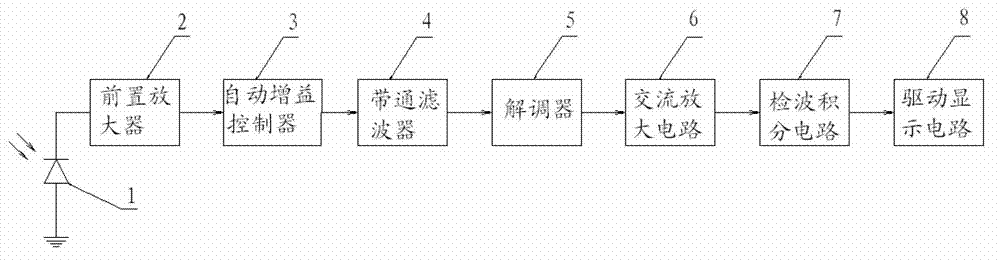

[0026] figure 1 The structure of the OBS working state detector provided by the first embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0027] The OBS working status detector provided in this embodiment includes:

[0028] The photosensitive receiving part 1 is used to sense the infrared modulation signal sent by the OBS and generate an induced current;

[0029] A preamplifier 2, configured to amplify the induced current generated by the photosensitive receiving component 1;

[0030] Automatic gain controller 3, used for stabilizing the magnification of the induced current;

[0031] A bandpass filter 4 is used to filter out the interference signal in the amplified induced current;

[0032] The demodulator 5 is used to demodulate the weak AC signal from the filtered induced current;

[0033] AC amplifier circuit 6, configured to amplify the demodulated AC signal;

...

Embodiment 2

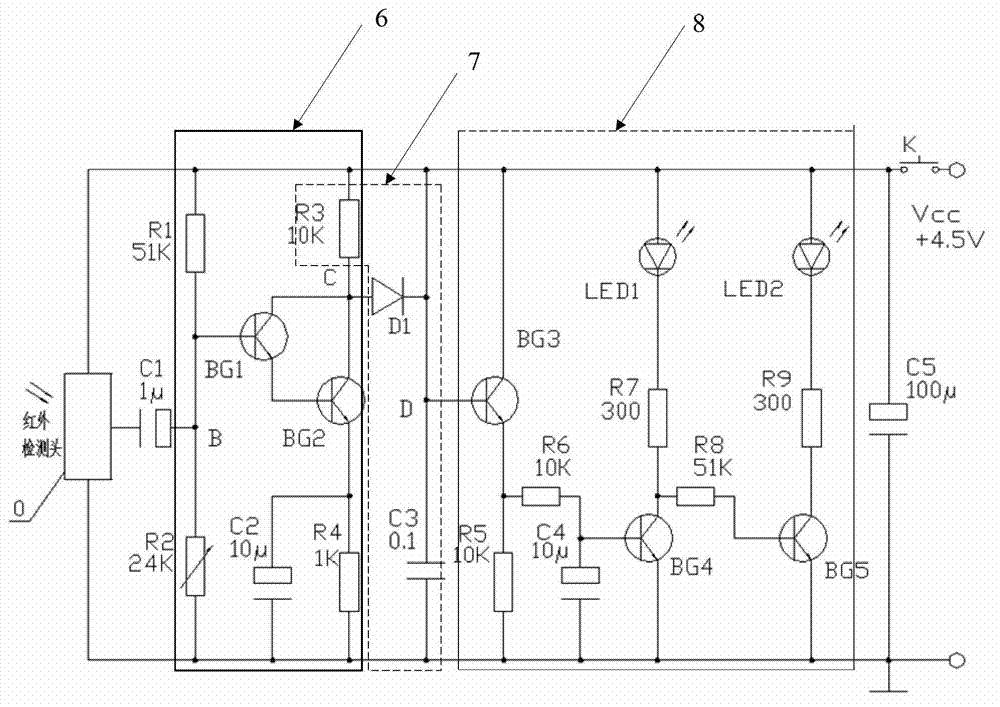

[0039] figure 2 The structure of the OBS working state detector provided by the second embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

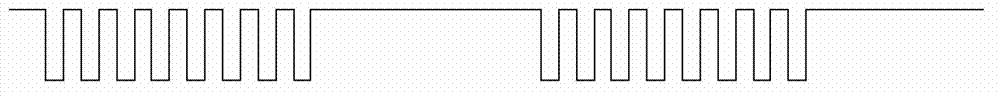

[0040] The OBS working state detector provided in this embodiment includes the photosensitive receiving part 1, the preamplifier 2, the automatic gain controller 3, the bandpass filter 4, the demodulator 5, the AC amplifier circuit 6, Detection and integration circuit 7, drive display circuit 8, in specific implementation, as preferred, photosensitive receiving part 1, preamplifier 2, automatic gain controller 3, bandpass filter 4, demodulator 5 can be integrated wherein In the infrared detection head 0, when the OBS is working, a series of infrared modulation signals are sent out regularly. The infrared wavelength is 875nm, and the modulation frequency is 500Hz. After the infrared detection head 0 detects the signal, its output term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com