Online neural network inverse controller in biological fermentation process and construction method of controller

A neural network inverse and biological fermentation technology, which is applied to the field of online decoupling controller and its construction in biological fermentation process, can solve the problems of closed-loop control performance decline, neural network generalization ability decline, inability to meet real-time performance, etc., to improve quality and yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

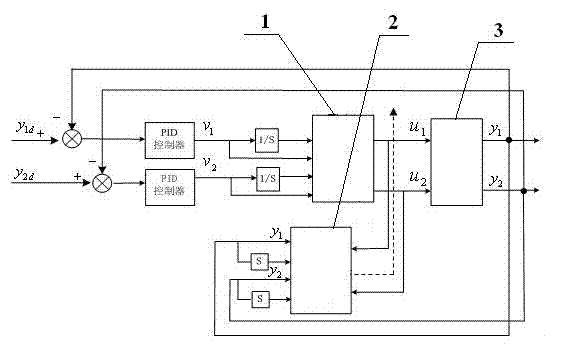

[0023] The online neural network inverse controller of the biological fermentation process of the present invention comprises two parts:

[0024] 1. Neural network inverse offline decoupling controller construction module 1.

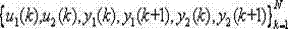

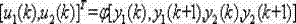

[0025] For the uncertain two-input and two-output biological fermentation system, the right reversibility of the system is analyzed according to the inverse system theory, and the relative order of the system and the input and output variables of the inverse system are determined; the offline acquisition system data trains the neural network to approximate the inverse system, and the The trained neural network is connected in series with the controlled system to form a pseudo-linear composite system to realize the linearization and decoupling of the controlled system.

[0026] 2. Neural network inverse online learning module 2.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com