Pressing method for sandwich aluminum-base printed circuit board

A technology for printed circuit boards and aluminum substrates, used in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of resin voids in the holes, bowing of the board, and inability to fill the through holes of aluminum substrates, and achieves increased bonding. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

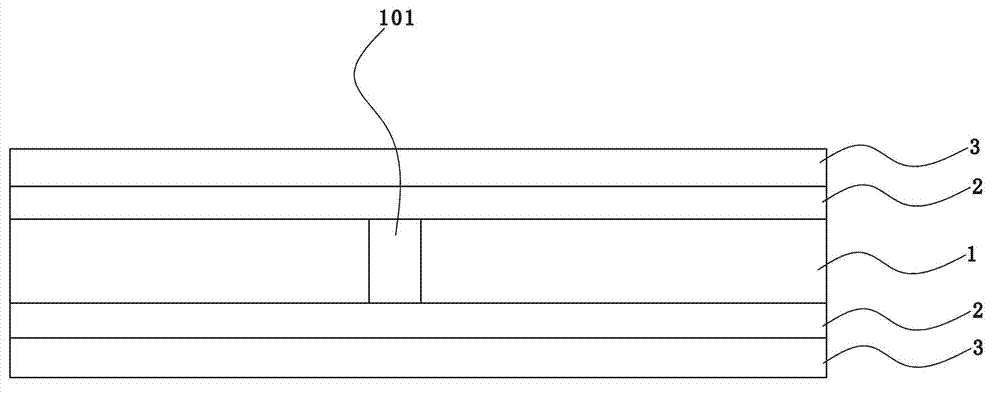

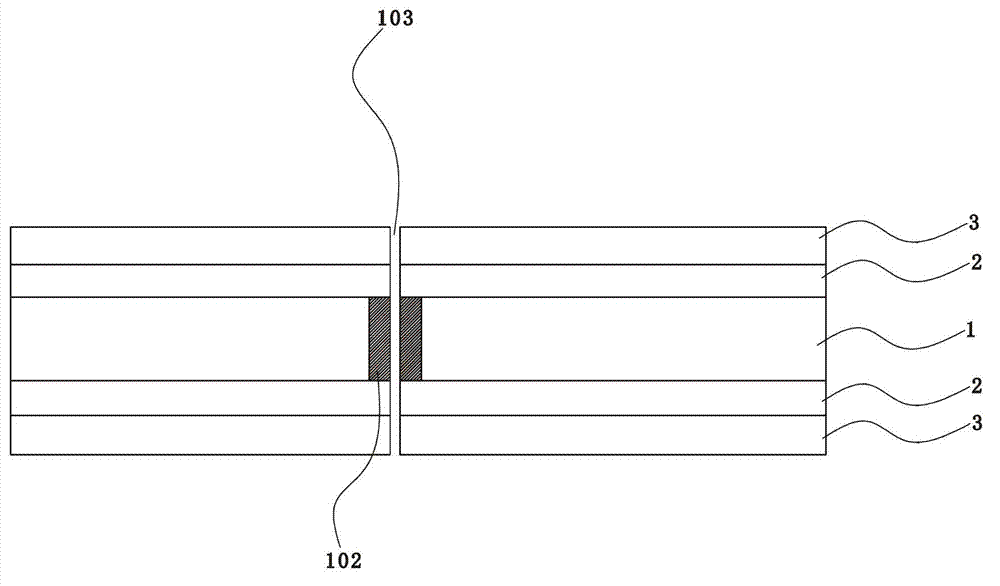

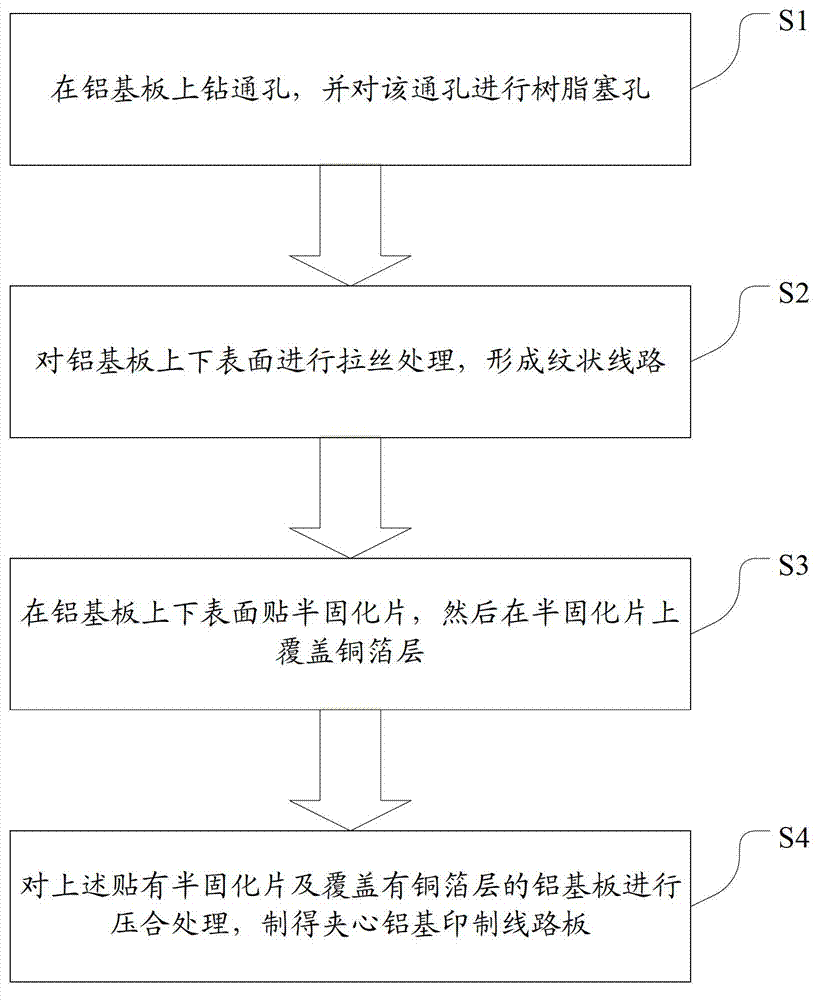

[0029] The core idea of the present invention is: fill resin in the through hole on the aluminum substrate, and carry out wire drawing treatment on the upper and lower surfaces of the aluminum substrate, so that the surface of the aluminum substrate forms a pattern of lines, and then paste prepreg on the upper and lower surfaces of the aluminum substrate, and on the prepreg Cover the copper foil layer, then laminate the board to make a sandwich aluminum-based printed circuit board, and finally drill a hole in the sandwich aluminum-based printed circuit board so that the hole in the hole penetrates the entire board, and It is located in the aluminum substrate filling resin, so that the connection between the upper and lower copper foil layers is formed.

[0030] See figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com