Novel automatic candy making machine

An automatic and candy technology, applied in the fields of confectionery, confectionery industry, food science, etc., can solve the problems of easy damage, inability to repair equipment, labor-intensive workers, etc., and achieve good self-lubrication, easy maintenance, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

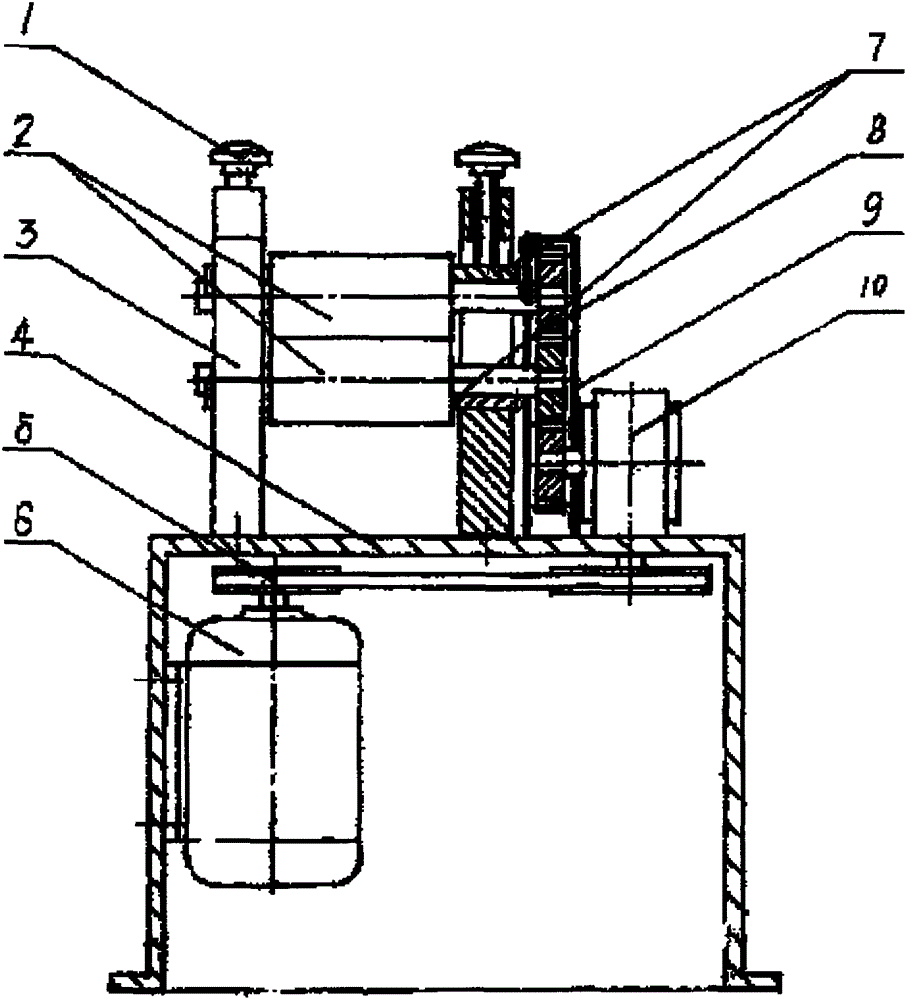

[0009] like figure 1 Shows the specific implementation of a new type of automatic candy machine of the present invention: a new type of automatic candy machine, including: power motor 6, belt transmission mechanism 5, worm gear reduction device 10, gear box 9, copper roller 2, copper tile 7 , adjust the screw mandrel 1, the frame 3 and the base 4, place the power motor 6 in the base 4, drag the input shaft of the worm gear reducer 10 installed vertically through the transmission belt 5, and the output shaft of the worm gear reducer is installed horizontally , directly stretch into the gear reduction box 8, and drive two copper rolls 2 engraved with patterns to move relative to each other through the gears.

[0010] Copper rolls 2 engraved with different patterns replace each other.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap