Automatic conveying ultrasonic cleaning machine for double-chain hanging frame

An automatic conveying and double-chain conveying technology, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as affecting the environment, high labor intensity, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

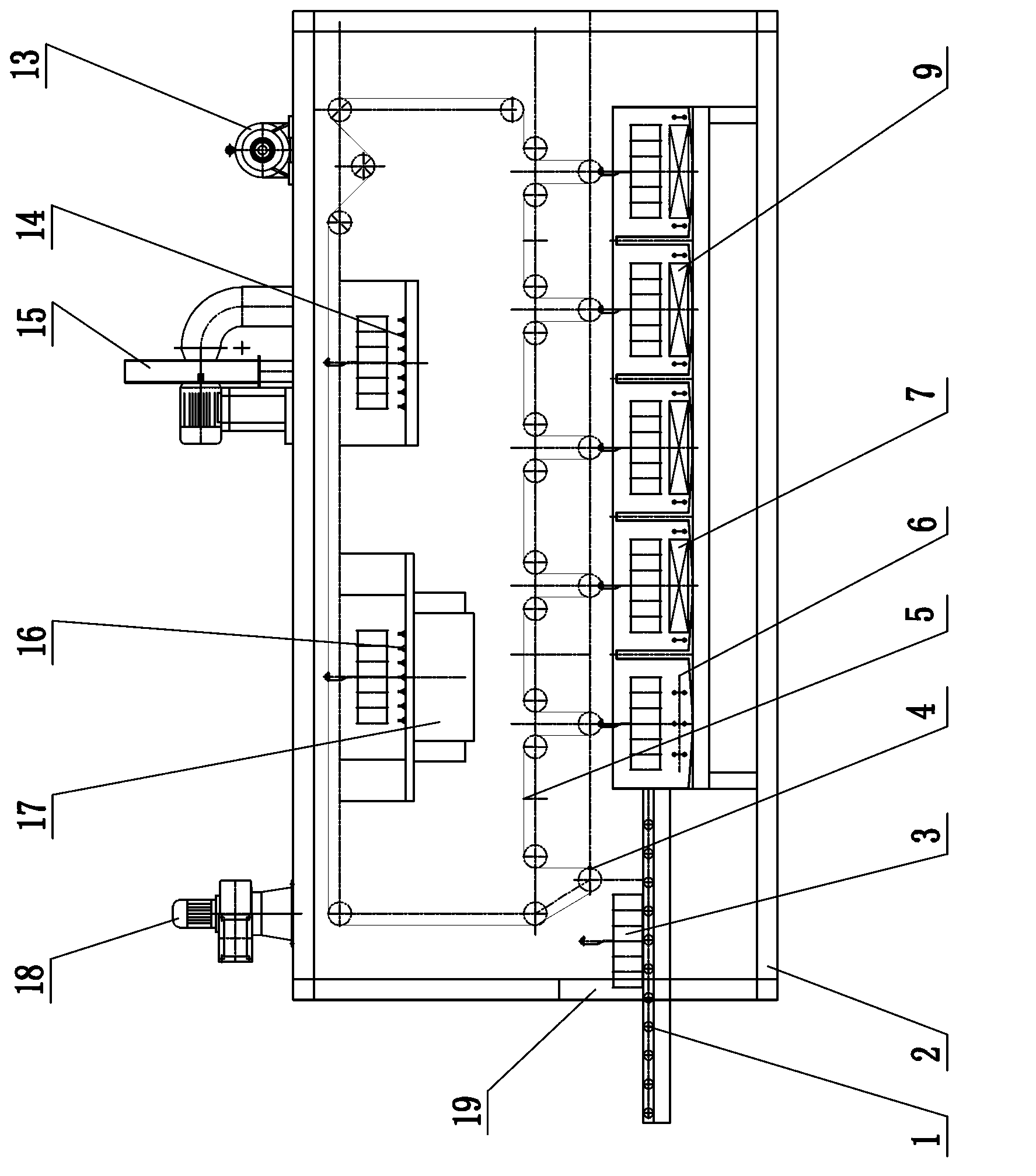

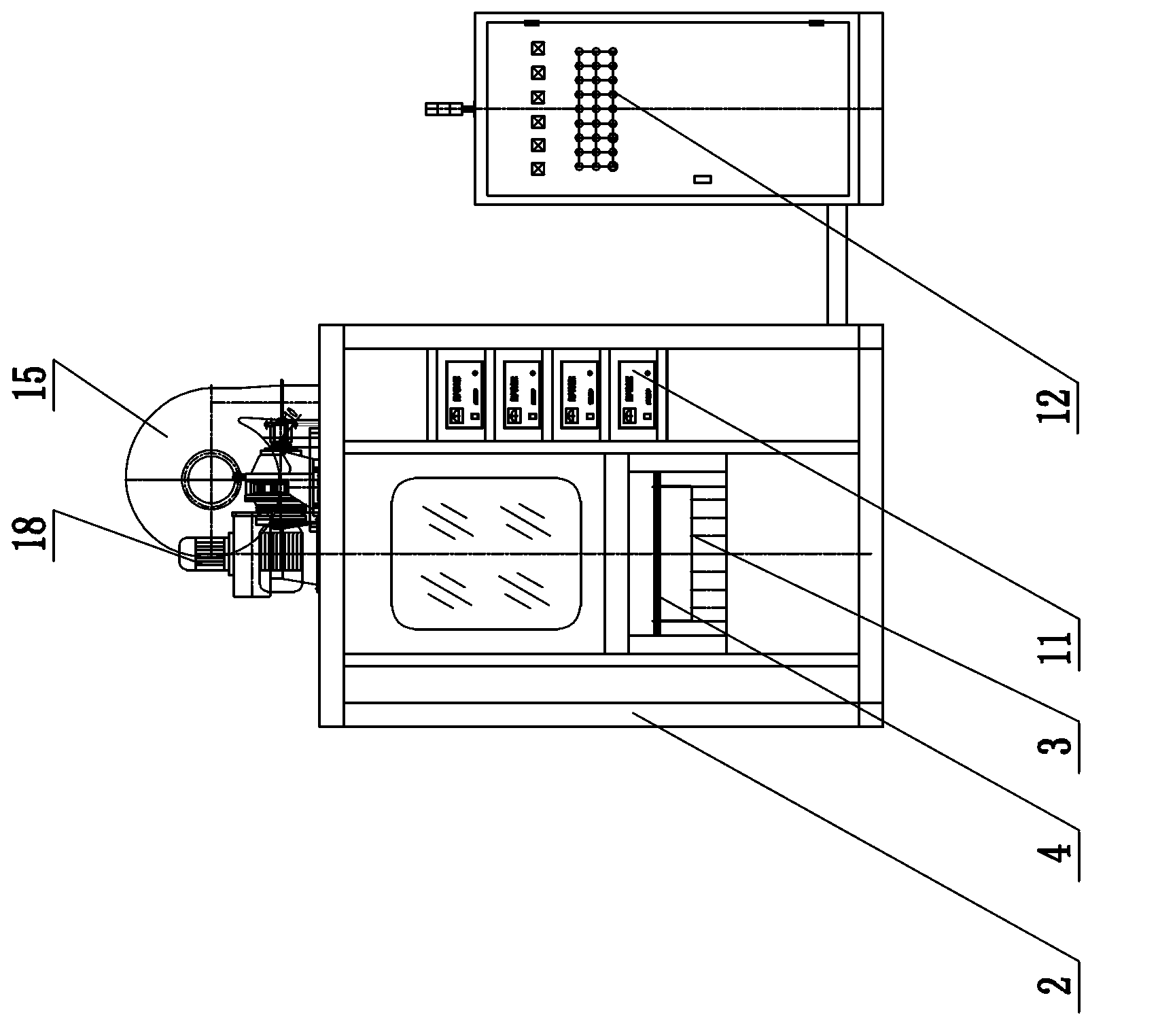

[0011] The double-chain hanging frame automatically transports the ultrasonic cleaning machine. An electrical control system 12 is provided on the body 2. An inlet and outlet 19 are provided on the body 2. An in-out material conveying raceway 1 is set up in the inlet and outlet 19. Inside the body 2 A double-chain conveying system 5 is provided, and a beam-type boom 4 is arranged between the inner and outer chains of the double-chain conveying system 5, and a high-temperature soaking tank 6, an ultrasonic The cleaning tank 7 and the ultrasonic rinsing tank 9 are provided with an ultrasonic controller 11 controlling the ultrasonic wave generation source in the ultrasonic cleaning tank 7 and the ultrasonic rinsing tank 9 on the body 2, and an exhaust fan 18 is fixed on the upper surface of the top plate of the body 2. High-pressure fan 15 and deceleration transmission system 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com