Method and equipment for high polymer material slope pin roller size extensional rheology plasticization transportation

A polymer material and slope technology, which is applied in the field of polymer material slope roller volume extensional rheological plasticization and transportation, can solve the problems of high energy consumption, poor material adaptability, low efficiency, etc., and achieves wide material adaptability, The effect of reducing the energy consumption of plasticizing transportation and high plasticizing transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

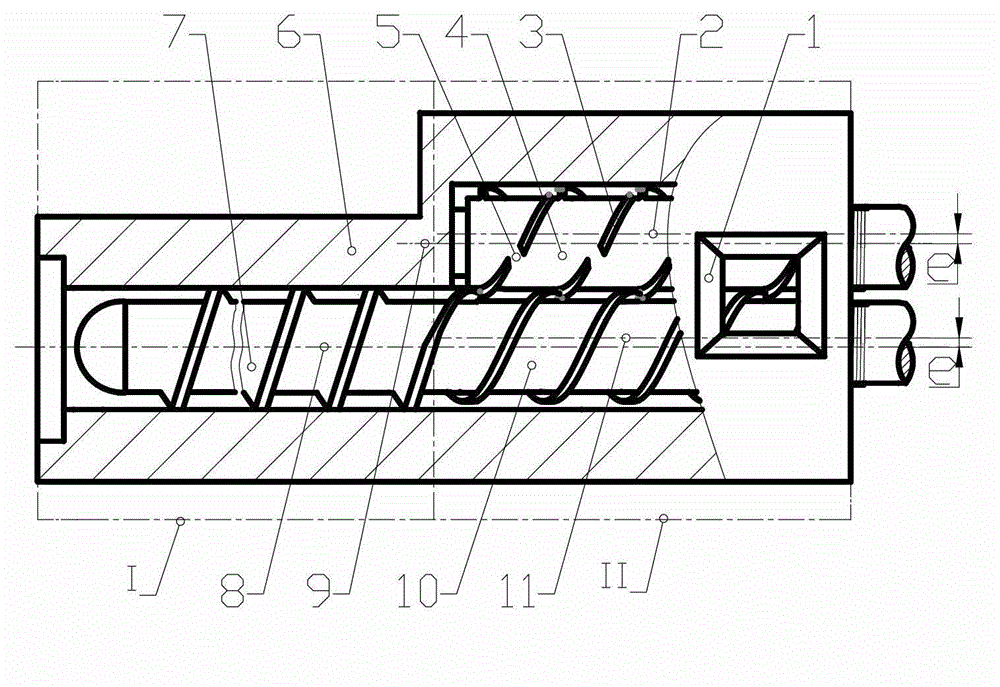

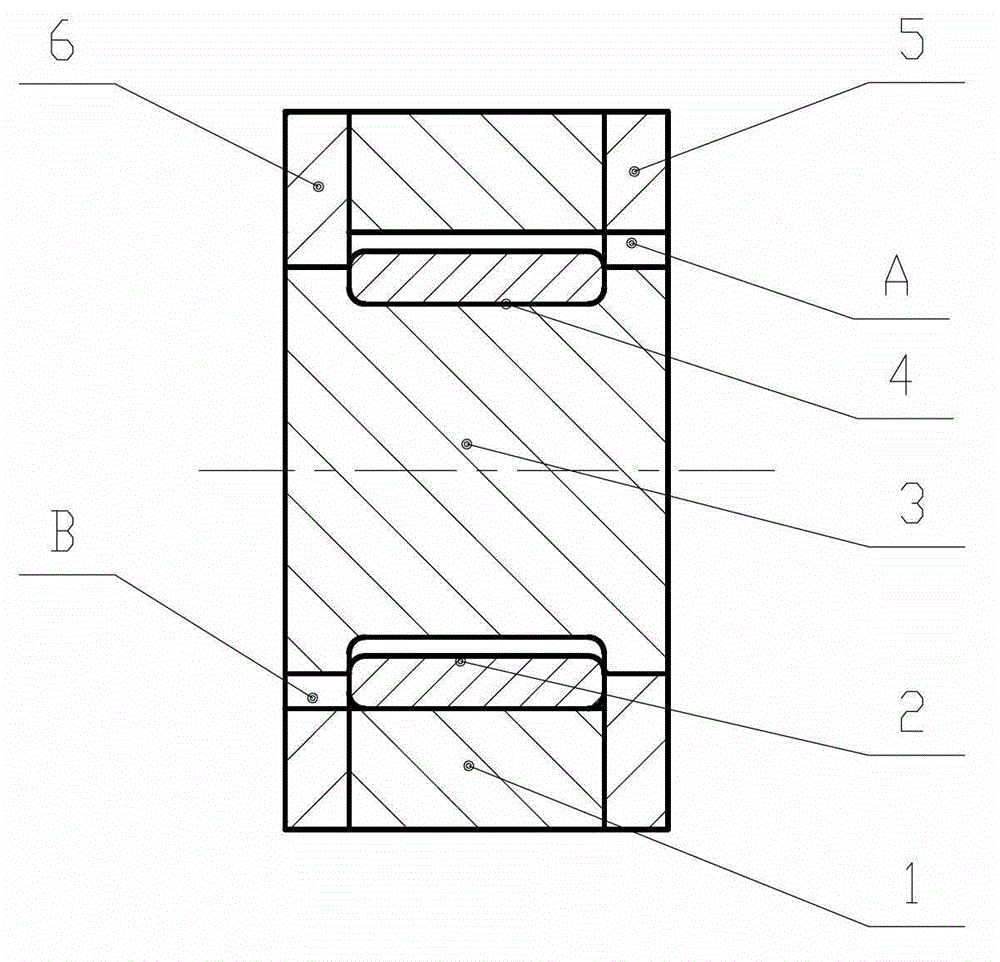

[0023] refer to figure 1 , figure 2 , polymer material inclined roller volume extensional rheological plasticization transportation equipment is an inclined roller plasticization transportation unit, which is mainly composed of a hollow stator 1 with a cylindrical inner cavity, placed in the inner cavity of the stator 1 and connected with the stator 1 The eccentric cylindrical rotor 3, the rollers 2 arranged in the inclined groove 4 of the rotor 3, and the first baffle 5 and the second baffle 6 arranged on both sides of the rotor are composed. The rotor 3 is installed eccentrically in the hollow stator 1. The eccentricity between the rotor 3 and the stator 1 can be adjusted, and its value is greater than 0 and smaller than the difference between the radius of the inner cavity of the stator and the radius of the rotor. One-half of the difference in radius is less than the difference between the radius of the inner cavity of the stator and the radius of the rotor. The rollers...

Embodiment 2

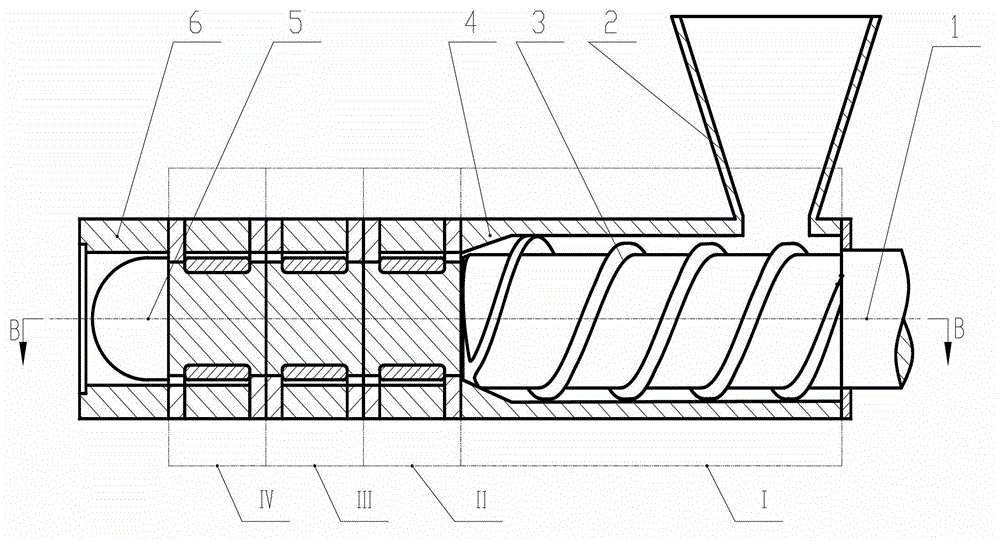

[0025] Such as image 3 and Figure 4 As shown, the screw inclined roller plasticizing extruder is mainly composed of screw extrusion unit I, inclined roller plasticizing units II, III, IV, drive shaft 1, hopper 2, flow divider 5 and transition sleeve 6. The screw extrusion unit I includes a screw 3 and a barrel 4; the screw extrusion unit I and the inclined roller plasticizing units II, III, and IV are installed in series; that is, the screw extrusion unit I and the inclined roller plasticizing units II, III and IV are set sequentially from right to left. The rotors of the inclined roller plasticizing units II, III, and IV are coaxially fixedly connected with the screw rod 3, and the screw rod 3 is coaxially fixedly connected with the drive shaft 1. The hopper 2 is fixed on the barrel 4 of the screw extrusion unit I, the first baffle of the inclined roller plasticizing unit II is concentrically fixedly connected with the barrel 4 of the screw extrusion unit I, and the first...

Embodiment 3

[0027] Such as Figure 5 As shown, the inclined roller plasticizing injection device is mainly composed of the full inclined roller plasticizing extruder I, the plunger injection unit II and the collector 1; among them, the structure and working of the full inclined roller plasticizing extruder I The principle is completely the same as that of the screw inclined roller plasticizing extruder in Example 2; the plunger injection unit II is mainly composed of an injection cylinder 2 , an injection piston 3 , an injection barrel 4 and a nozzle 5 . The feed end face of the material collector 1 and the transition sleeve 6 of the fully inclined roller plasticizing extruder 1 (see image 3 , 4 ) on the discharge end face is fixedly connected, and the discharge end face of the collector 1 is fixedly connected with the feed end face of the injection barrel 4 of the plunger injection unit II. The melt plasticized by the fully inclined roller plasticizing extruder I enters the injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com