Overall manufacturing process for anchor platform of drilling ship and structure of anchor platform

A technology for overall production and drilling of ships, applied in ship parts, ship construction, ships, etc., can solve the problems of harsh construction operation environment, unfavorable welding and improvement of operation environment, low production efficiency, etc., to improve production efficiency and welding quality, Beneficial to personal safety, installation and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

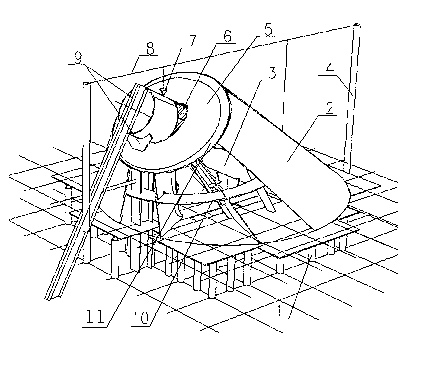

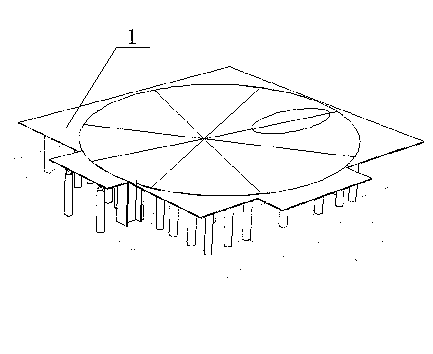

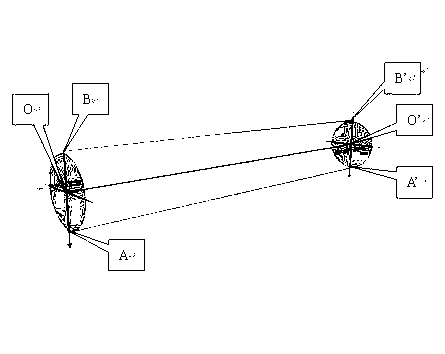

[0022] Such as Figure 1-Figure 6 As shown, the anchor platform structure produced by the overall manufacturing process of the drilling ship anchor platform includes tire frame 1, anchor platform outer plate 2, anchor chain pipe 3, anchor lip 5, internal frame 10 and sealing plate 11, and anchor platform outer plate 2 is fixed On the internal frame 10, the top of the anchor platform outer plate 2 is connected with the anchor lip 5 through the sealing plate 11, the upper part of the internal frame 10 is fixed with the anchor chain pipe 3, and the lower part is fixedly connected with the positioning line on the tire frame 1, and the anchor platform outer plate 2 The overall production process of the anchor platform of the drilling ship includes the following steps: step A, making the tire frame and drawing the center line of the tire frame and the installation line of the anchor platform structure on the tire frame , the anchor platform is built horizontally on the horizontal ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com