Belt feeding, withdrawing and tensioning device of packer

A technology of tightening belts and sending and unwinding belts, which is applied to the parts of strapping machinery, etc., can solve the problems of complex structure and high frequency of work failures, and achieve the effects of reducing failure rate, good packaging effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

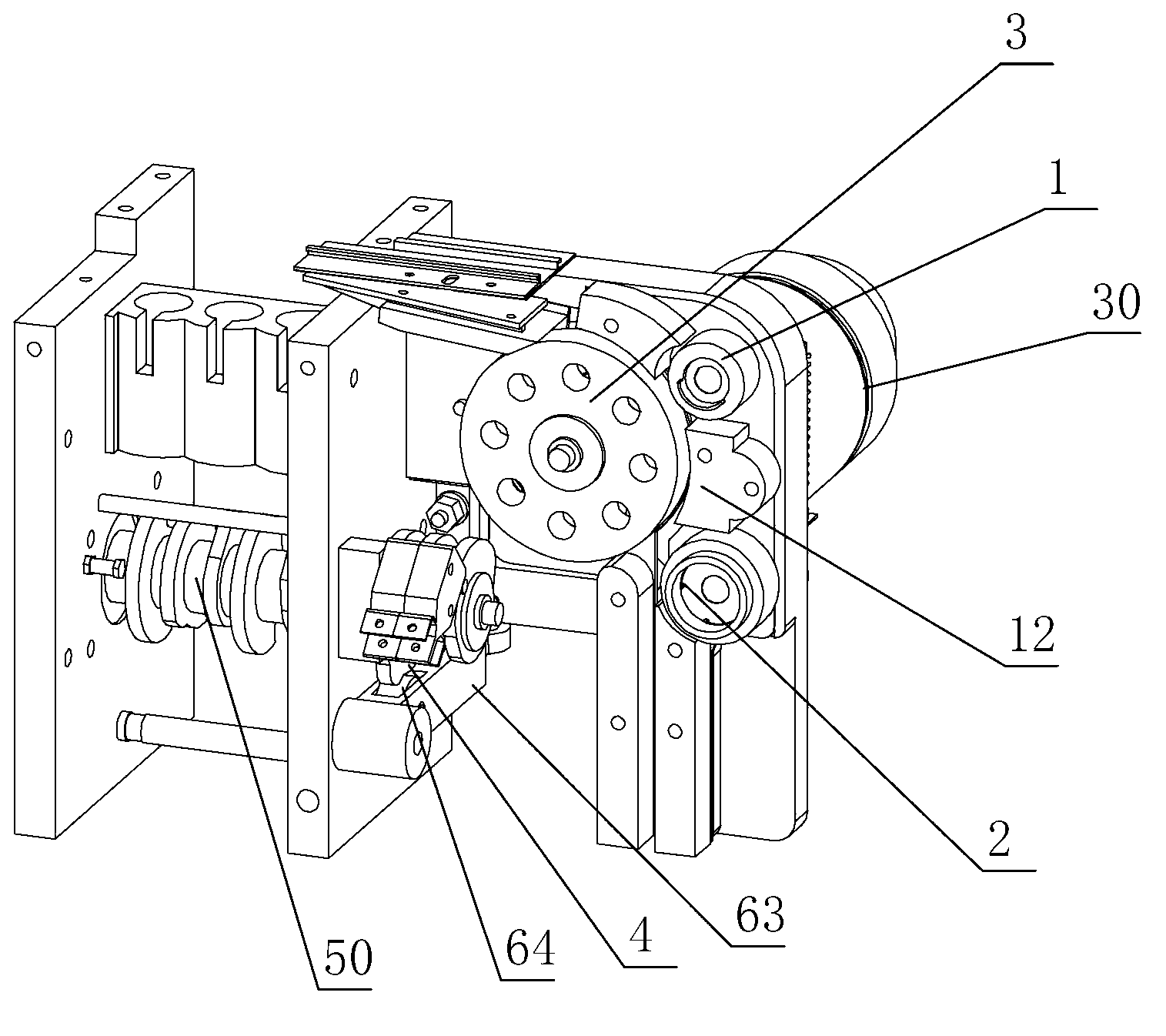

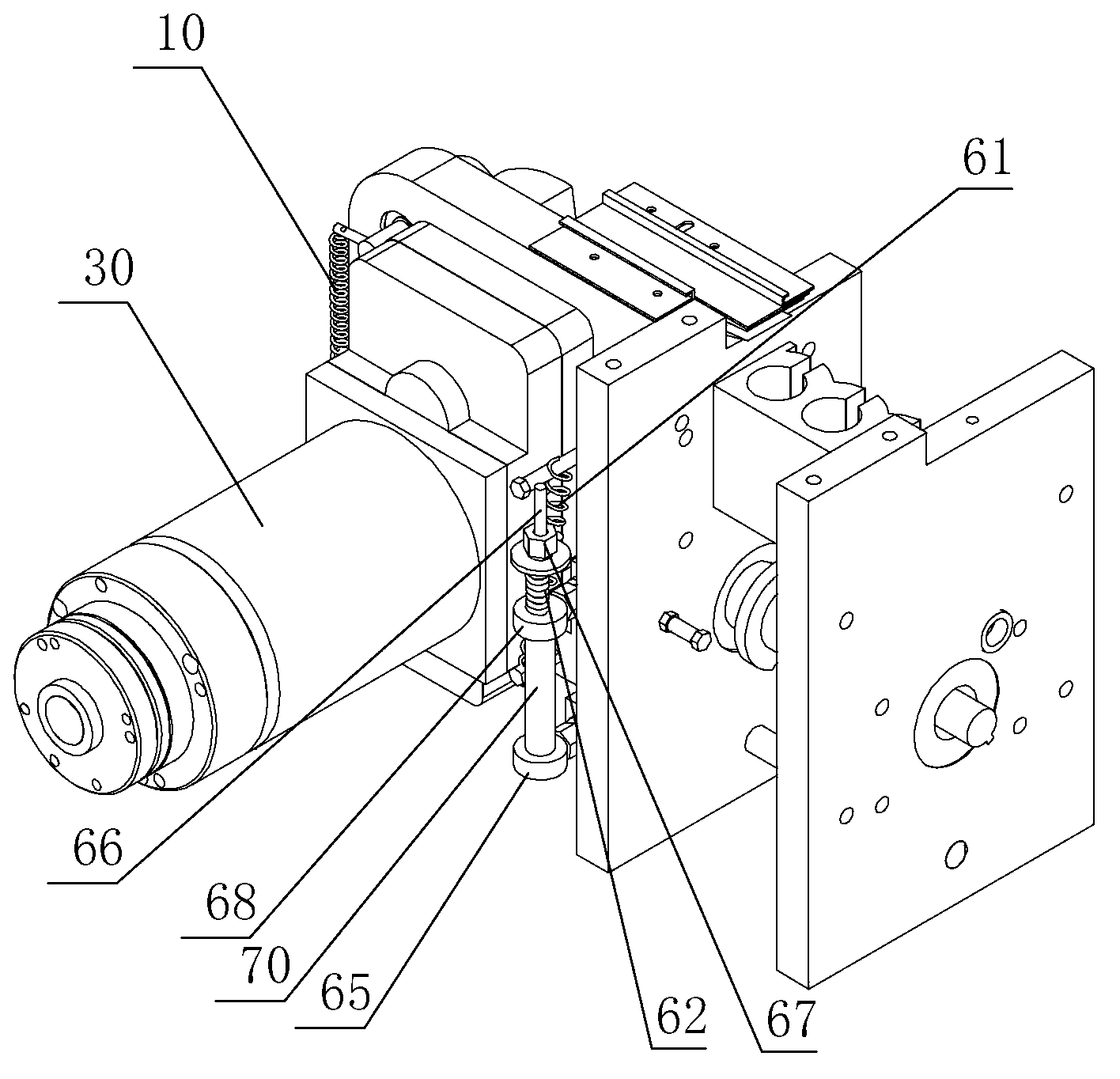

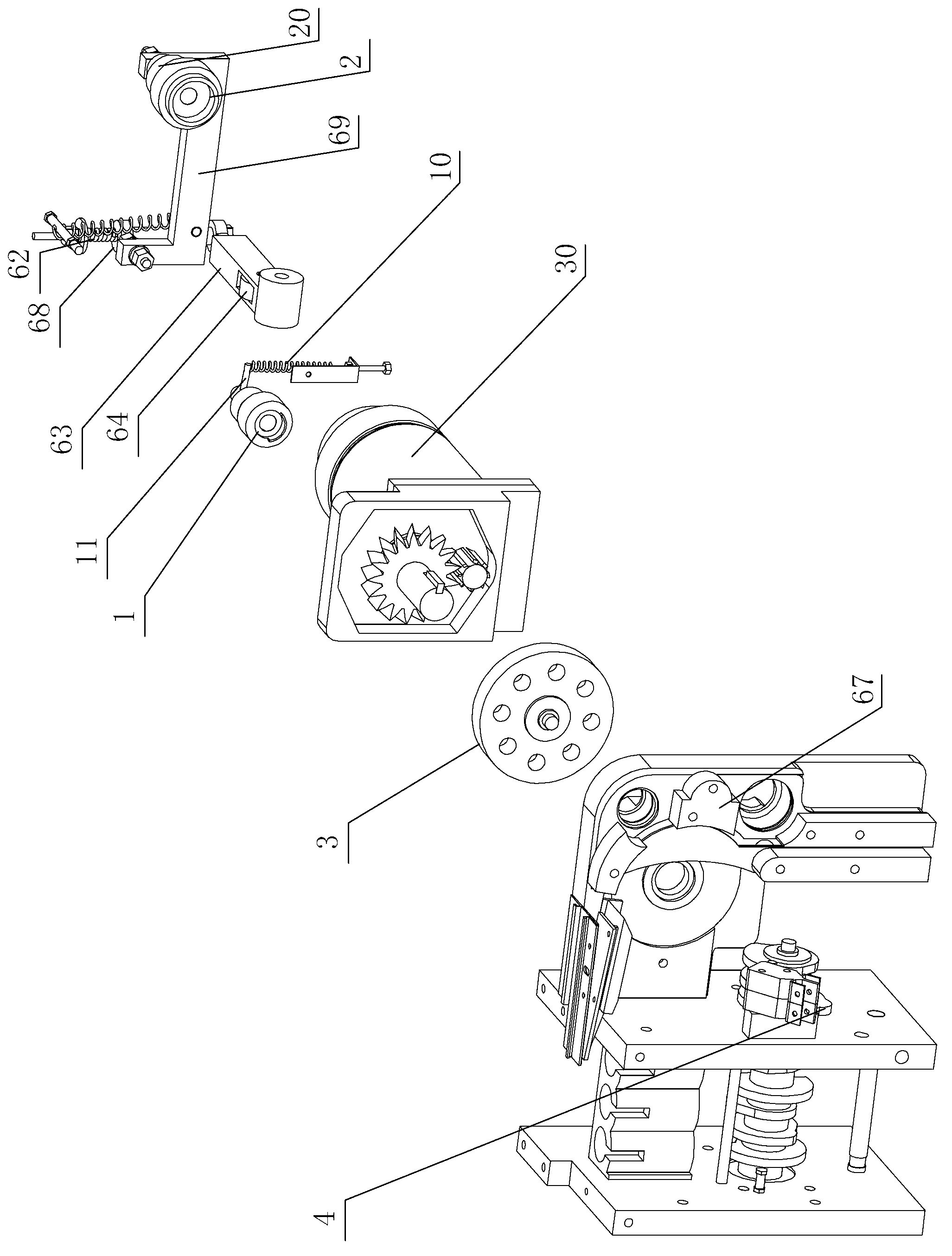

[0014] Refer to attached picture. The present invention comprises driving roller 3, the first driven roller 1, the second driven roller 2, according to the belt-feeding direction of packing belt, the first driven roller 1 is in the downstream of the second driven roller 2;

[0015] Both the first driven roller 1 and the second driven roller 2 are installed eccentrically; the first driven roller 1 is driven by the spring 10 to always lean against the driving roller 3, and the second driven roller 2 leans against the driving roller 3 through the control of the cam 4. On the driving roller 3 and away from the driving roller 3. Reference numeral 30 is the driving motor of the driving roller.

[0016] The spring 10 can drive the first driven roller 1 to always lean against the driving roller 3 through the connection mechanism. For example, the shaft of the first driven roller 1 is connected to the spring 10 through a connecting rod 11 .

[0017] Between the first driven roller 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap