Bearing auto-feed device

A technology of automatic feeding and feeding, which is applied in the directions of conveyor objects, transportation and packaging, skids, etc., can solve the problems of unqualified products and low production efficiency, and achieve the effect of improving work efficiency and product qualification rate and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

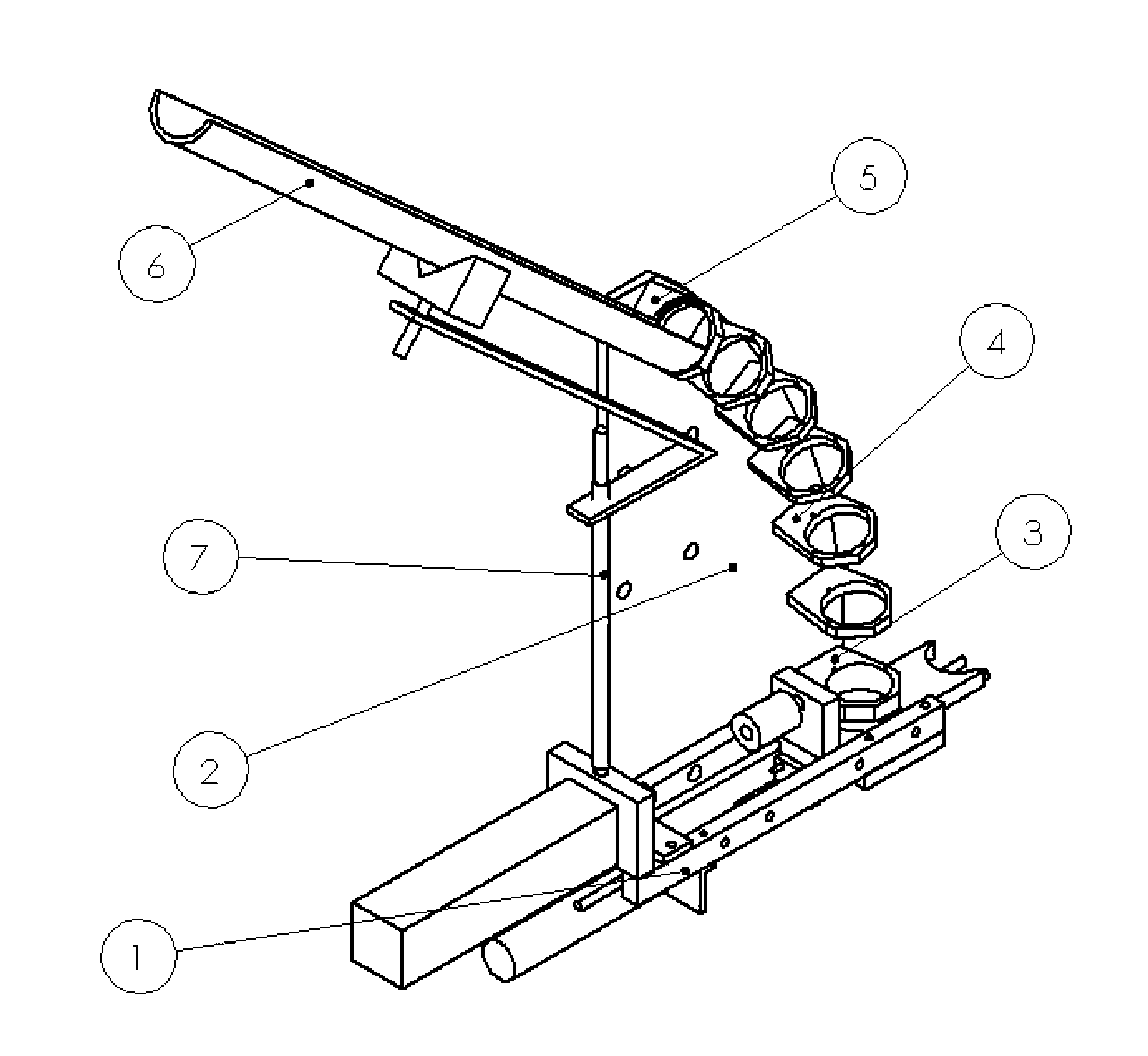

[0032] see figure 1 , including in the figure: feeding fixed plate 2, feeding half pipe 6, support rod 7, feeding upper bending ring 5, feeding middle bending ring 4, feeding lower bending ring 3 and feeding mechanism 1. The upper bending ring 5 for feeding, the middle bending ring 4 for feeding, the lower bending ring 3 for feeding and the feeding mechanism 1 are fastened on the feeding fixed plate 2 respectively. Feeding semi-pipe 6 one end is stuck on the upper bending ring 5 of feeding, and the other end is supported by support rod 7, and support rod 7 is fastened on the feeding mechanism 1.

[0033] The feeding half-pipe 6 in this embodiment is an elongated tile-mounted structure, and the inner surface of the tile-mounted structure is the running channel of the bearing. The feeding channel is composed of the feeding half pipe 6, the feeding upper bending ring 5, the feeding middle bending ring 4, and the feeding lower bending ring 3. Here, a straight feeding channel can ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap