Preparation and application of long-acting anticorrosion temperature-resistant coating

A coating and silicone technology, applied in the field of preparation of long-acting anti-corrosion and heat-resistant coatings, the above-mentioned phenolic epoxy modified silicone resin, can solve the problem of less coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

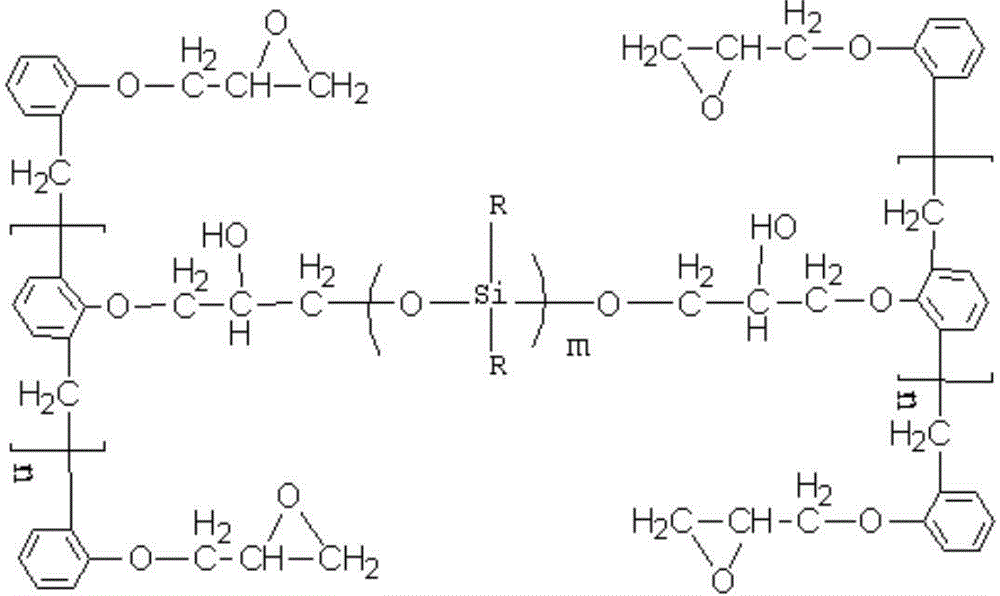

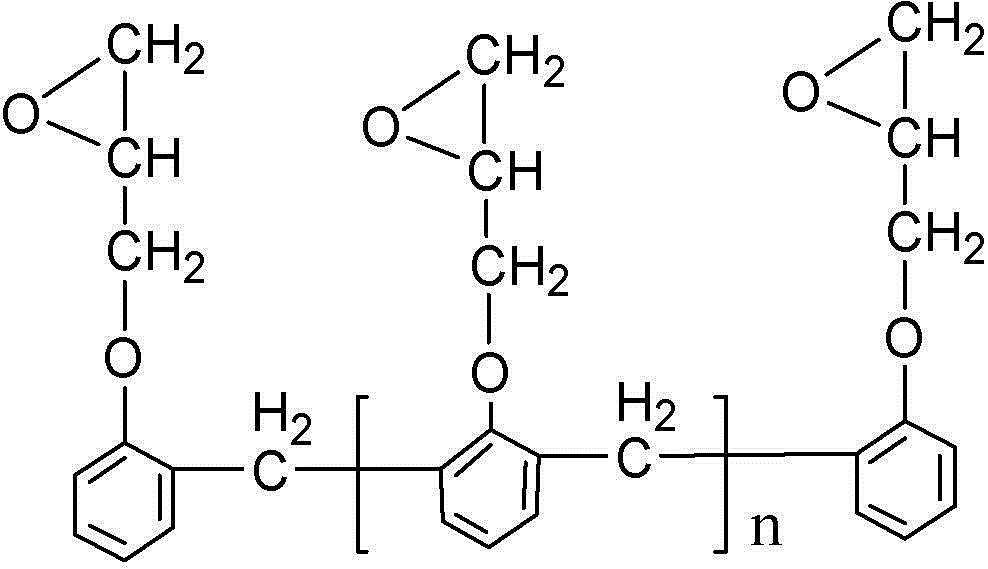

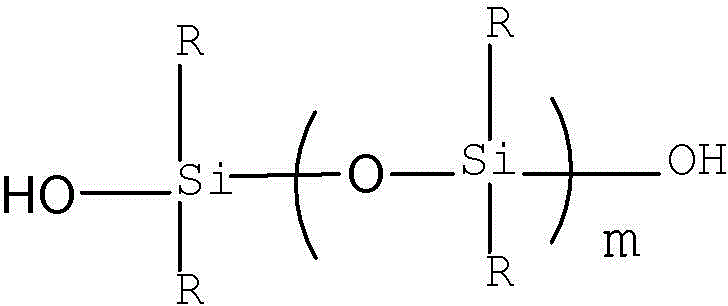

[0051] Embodiment 1: Preparation of Novolac Epoxy Modified Silicone Resin

[0052] Add 20 parts of xylene to 80 parts of F44 (domestic) and mix and dissolve under heating and stirring. The solution is a uniform light yellow transparent liquid. The cyclohexanone is stirred and heated up, and reacted at 80-100° C. for 8-10 hours. Obtain 200 parts of transparent homogeneous viscous novolak epoxy modified silicone resin. Measured by infrared absorption spectrum at 1128cm -1 、1095cm -1 and 1022cm -1 The characteristic absorption peak of silicon-oxygen bond appears, and the 918 cm -1 and 910cm -1 The characteristic absorption peak of the nearby epoxy group weakens and disappears, which proves that the corresponding novolac epoxy modified silicone resin target product is obtained through the synthesis reaction.

Embodiment 2

[0053] Embodiment 2: Preparation of Novolac Epoxy Modified Silicone Resin

[0054] Add 10 parts of benzene to mix and dissolve 40 parts of DEN438 (Dow company in the United States) under heating and stirring. The solution is uniform light yellow transparent liquid. company), and 109.5 parts of butyl acetate were stirred and heated up, and reacted at 100-120°C for 6-8 hours. Obtain 200 parts of transparent homogeneous viscous novolak epoxy modified silicone resin. Measured by infrared absorption spectroscopy at 1130cm -1 、1100cm -1 and 1040cm -1 The characteristic absorption peak of silicon-oxygen bond appears, and the 918 cm -1 and 910cm -1 The characteristic absorption peak of the nearby epoxy group weakens and disappears, which proves that the corresponding novolac epoxy modified silicone resin target product is obtained through the synthesis reaction.

Embodiment 3

[0055] Embodiment 3: the preparation of novolak epoxy modified silicone resin

[0056] Add 30 parts of xylene to 70 parts of EPN1180 (Swiss Ciba Company) and mix and dissolve under heating and stirring. The solution is a uniform light yellow transparent liquid. ), and 48.5 parts of cyclopentanone were stirred and heated up, and reacted at 90-110° C. for 7-9 hours. Obtain 200 parts of transparent homogeneous viscous novolak epoxy modified silicone resin. Measured by infrared absorption spectrum at 1135cm -1 、1103cm -1 and 1015cm -1 The characteristic absorption peak of silicon-oxygen bond appears, and the 918 cm -1 and 910cm -1 The characteristic absorption peak of the nearby epoxy group weakens and disappears, which proves that the corresponding novolac epoxy modified silicone resin target product is obtained through the synthesis reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap