A kind of antibacterial resin composite material and preparation method thereof

A resin composite material and antibacterial technology, which is applied in the polymer field to achieve the effects of improving the bacteriostatic rate, good bacteriostasis and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

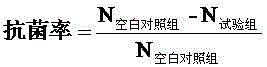

Embodiment 1

[0026] Disperse the weighed nano-magnesium oxide powder with ultrasonic waves in deionized water. According to the ratio of lanthanum chloride to magnesium oxide, add lanthanum chloride and adjust the pH of the solution to 4 with dilute hydrochloric acid. After stirring for 2 hours at a temperature of 60°C, the material was filtered, washed with distilled water three times, dried at 120°C, calcined for 3 hours, taken out and ground to make La 3+ / MgO antibacterial agent; and then mix 5 parts of the antibacterial agent prepared above with 100 parts of polyethersulfone resin, and extrude it at 250° C. to obtain an antibacterial polyethersulfone plastic. According to the calculation of antibacterial performance test, the antibacterial rate of this material to yeast reaches 92%.

Embodiment 2

[0028] Disperse the weighed nano-magnesium oxide powder in deionized water by ultrasonic wave. According to the ratio of lanthanum chloride to magnesium oxide, add lanthanum chloride and adjust the pH of the solution to 2 with acetic acid. After stirring for 1 hour at a temperature of 80°C, the material was filtered, washed with distilled water four times, dried at 150°C, calcined for 4 hours, taken out and ground to make La 3+ / MgO antibacterial agent; and then mix 8 parts of the antibacterial agent prepared above with 100 parts of polyether ether ketone resin, and extrude it at 350° C. to obtain antibacterial polyether ether ketone plastic. According to the calculation of antibacterial performance test, the antibacterial rate of this material against Gram-negative Escherichia coli reaches 96%.

Embodiment 3

[0030] Disperse the weighed nano-magnesium oxide powder with ultrasonic waves in deionized water. According to the ratio of lanthanum chloride to magnesium oxide, add lanthanum chloride and adjust the pH of the solution to 6 with dilute hydrochloric acid. Stir for 5 hours at a temperature of 60°C, filter the material, wash with distilled water five times, dry at 180°C, bake for 1 hour, take out and grind to make La 3+ / MgO antibacterial agent; and then mix 10 parts of the antibacterial agent prepared above with 100 parts of polyethylene glycol resin, and extrude and form at 80° C. to obtain antibacterial polyethylene glycol plastic. According to the calculation of antibacterial performance test, the antibacterial rate of the material against Gram-positive Staphylococcus aureus reached 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com