Combination line-shaped bearing cable suspension bridge and construction method thereof

A cable and linear technology, which is applied to a suspension bridge combined with linear load-bearing cables and its construction field, can solve the problems of small inclination angle of the suspension cable, small lateral stability of the carriageway beam, insufficient lateral stability, etc., and achieves enhanced stability and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

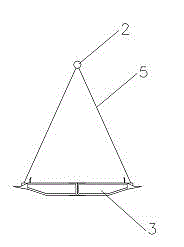

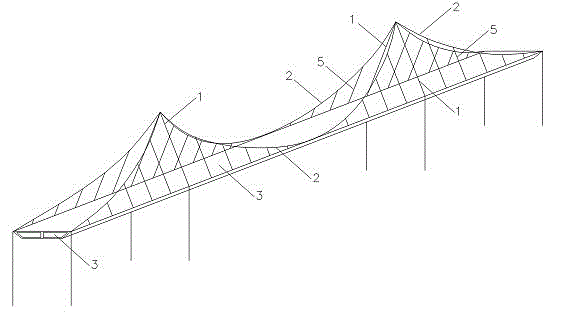

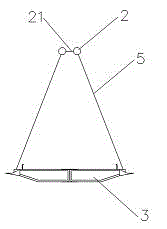

[0031] Such as image 3 , Figure 4 Shown, the suspension bridge of combined linear load-bearing cable of the present invention is made of bridge tower (1), load-bearing cable (2), carriageway beam (3), anchorage (4), sling (5), and load-bearing cable is made of two The two main cables are placed on two saddles on the top of the bridge tower (1). The distance between the saddles is less than the width of the carriageway girder and greater than 2 meters. The middle part of the mid-span is anchored on both sides of the carriageway girder (3) of the mid-span, and the two main cables are provided with a main cable displacement rod (24) between the bridge tower (1) and the mid-span anchor point of the mid-span, and the bridge tower The main cables to the displacement pull rods are parallel, and a strut (21) is arranged between the two main cables; wherein, the strut (21) has a hoop (241), which is controlled by the length of the pull rod (242). The distance between the main cable...

Embodiment 2

[0043] Such as Figure 8 As shown, the displacement pull rod of the present invention is composed of two baffles (243) and two pull rods (242), the two ends of the pull rods (242) are respectively connected to the two baffles (243), and the inside The side is in contact with the main cable, and its surface is consistent with the shape of the main cable at the corresponding position. The length of the tie rods is based on keeping the two main cables parallel between the bridge tower and the displacement tie rods, and is determined by calculation according to the overall stability and force requirements of the structure. Strength of tie rods (242) and baffles (243). Rigid rods are set between part of the cable clamps to form a strut together with the cable clamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com