Crankcase ventilation oil returning structure

A crankcase ventilation and crankcase technology, applied in crankcase ventilation, engine components, machines/engines, etc., can solve the problems of increasing the burden on the oil and gas separation system, increasing the degree of oil atomization, and reducing weight and fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

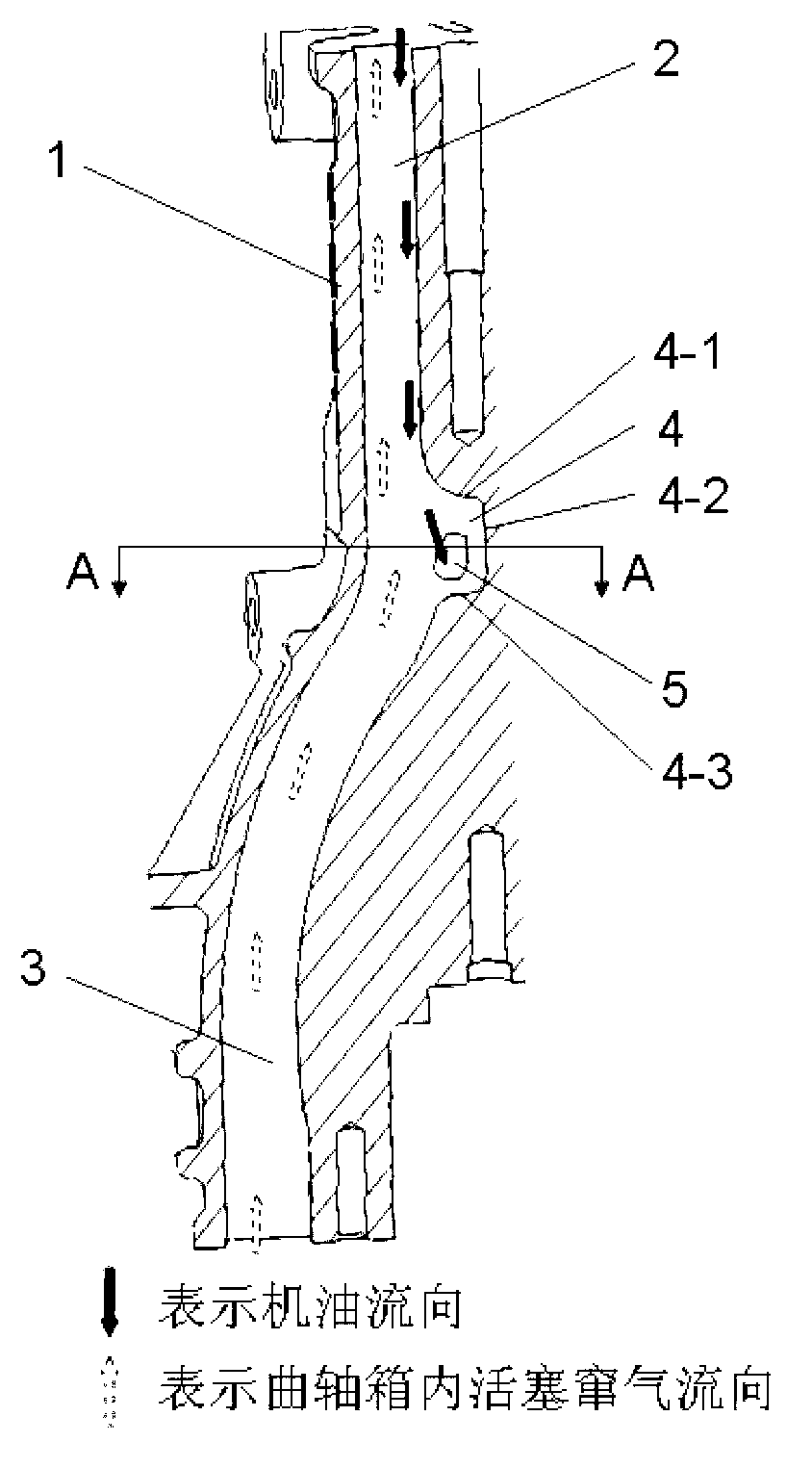

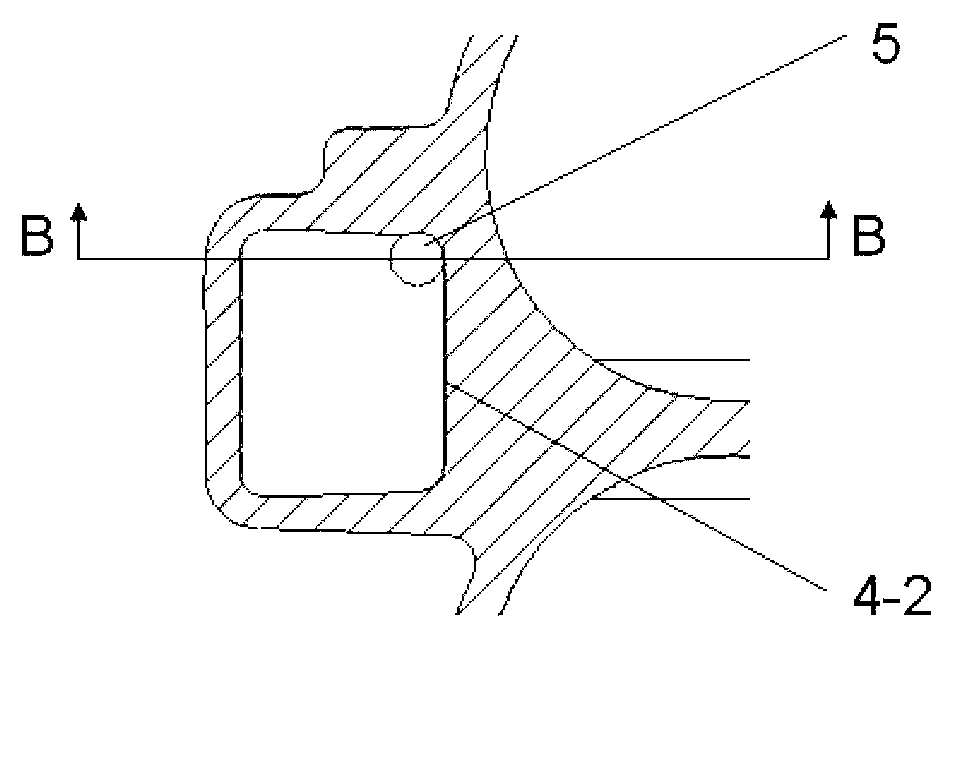

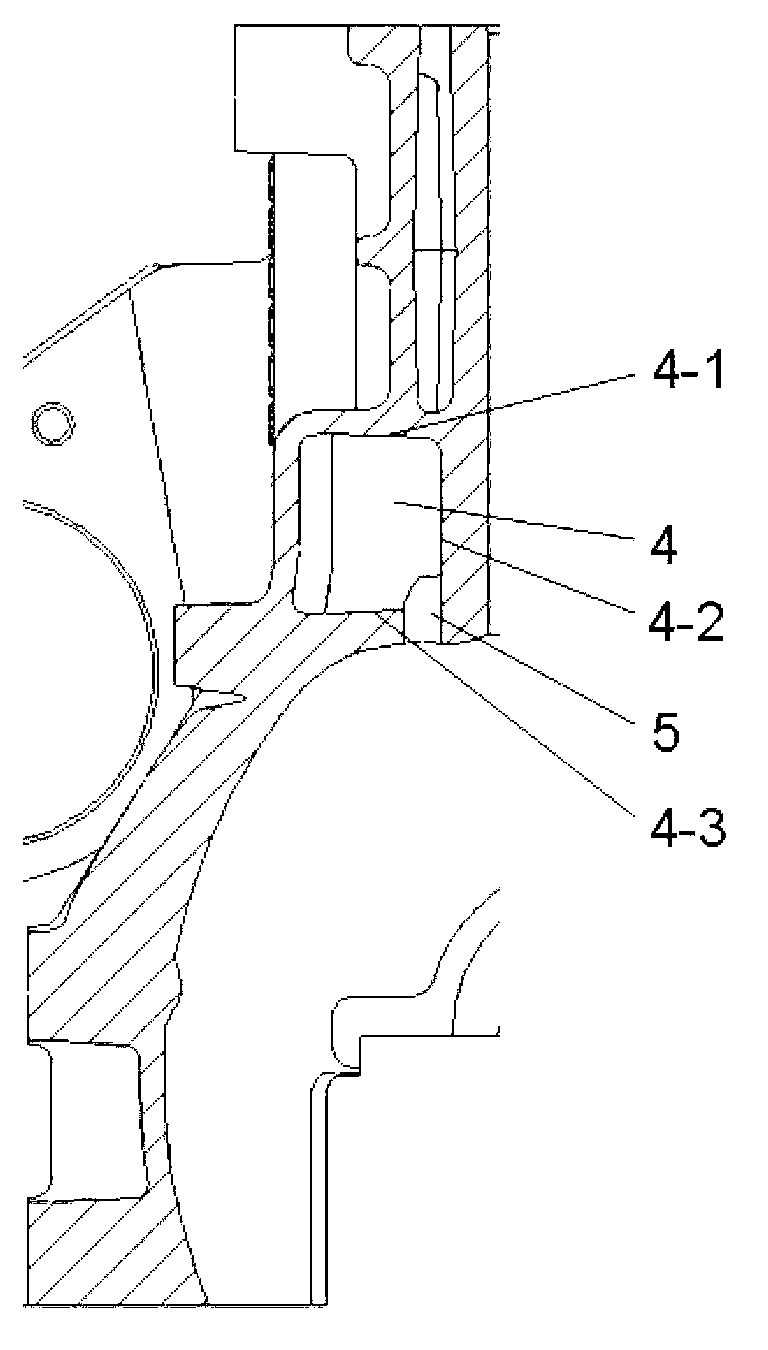

[0016] see figure 1 , a crankcase ventilation oil return structure, comprising a crankcase body 1 and a crankcase chamber in the crankcase body, a ventilation oil return passage is arranged on the crankcase body, and the ventilation oil return passage includes an upper section of the ventilation oil return passage 2 and the lower section 3 of the ventilation oil return channel, a groove 4 is arranged on the inner side of the channel at the junction of the upper section and the lower section of the channel, and an oil return hole 5 communicating with the crankcase chamber is opened in the groove.

[0017] see figure 1 , when the engine is working, in the ventilation oil return channel, the piston blow-by gas moves from bottom to top, through the channel upwards into the oil-gas separation system, the oil flows from top to bottom, when the oil flows to the end of the upper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com