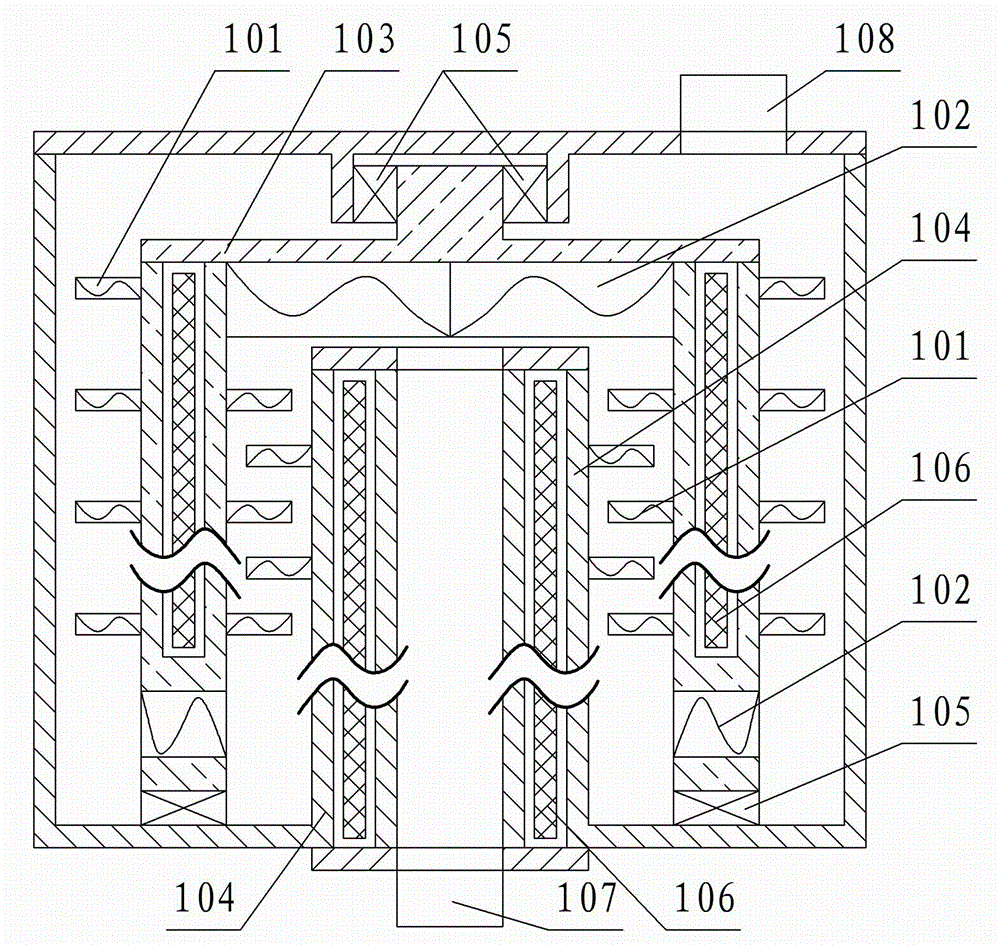

Axial-flow type integrated dewatering pump

A drainage pump and axial flow technology, applied in the field of axial flow integrated drainage pump, can solve the problems of low efficiency of manual winding coil motor, difficulty in maintenance of motor coil, difficulty in movement sealing, etc., and achieve convenient daily operation and maintenance, simple structure, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0046] The split structure coil 106 can be applied to existing motors. The split structure coil 106 can quickly find damaged coils on site, and can quickly and easily replace the standardized split structure coil 106 for maintenance without disassembling the motor.

Embodiment approach 2

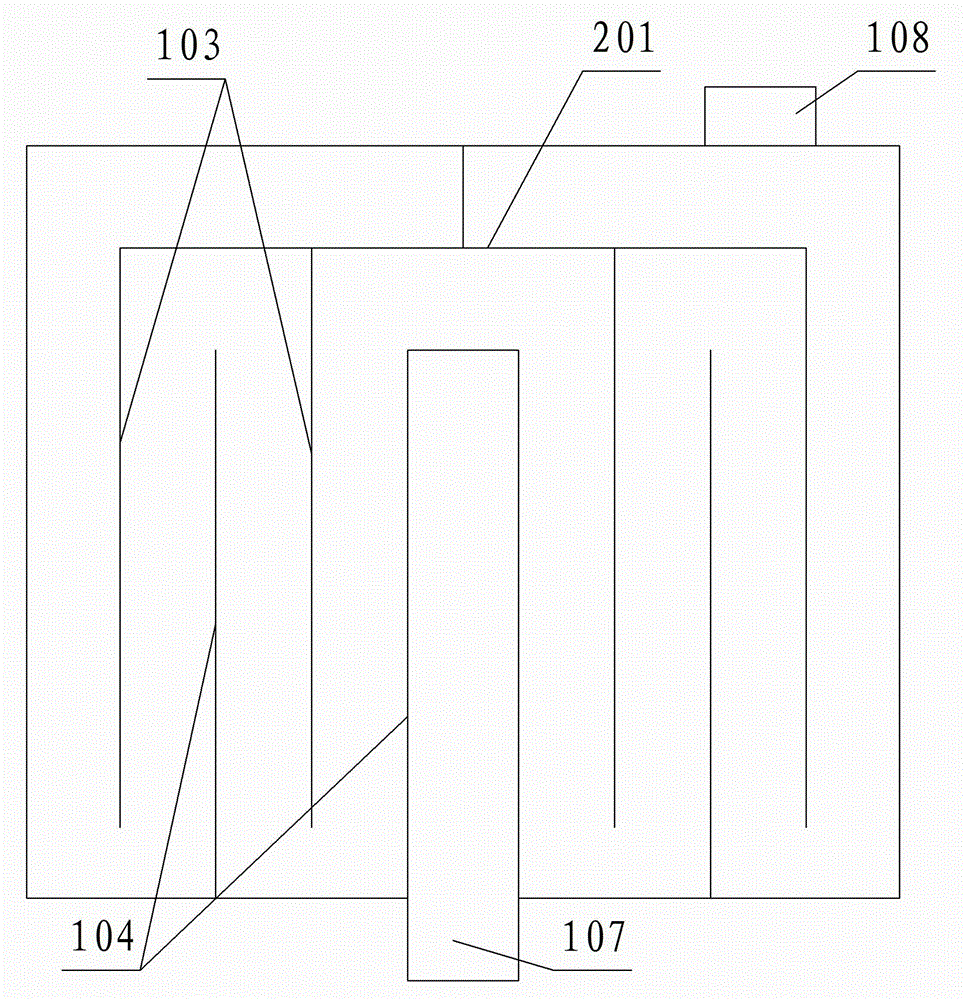

[0048] The axial-flow integrated drainage pump increases the head, can increase the number of layers of axial flow blades 101, increase the number of layers of radial rotors 103 to form a reciprocating pressurized structure, or increase the head by relaying in the pipeline, so that the large Head drainage pumps are bulky and take up space.

Embodiment approach 3

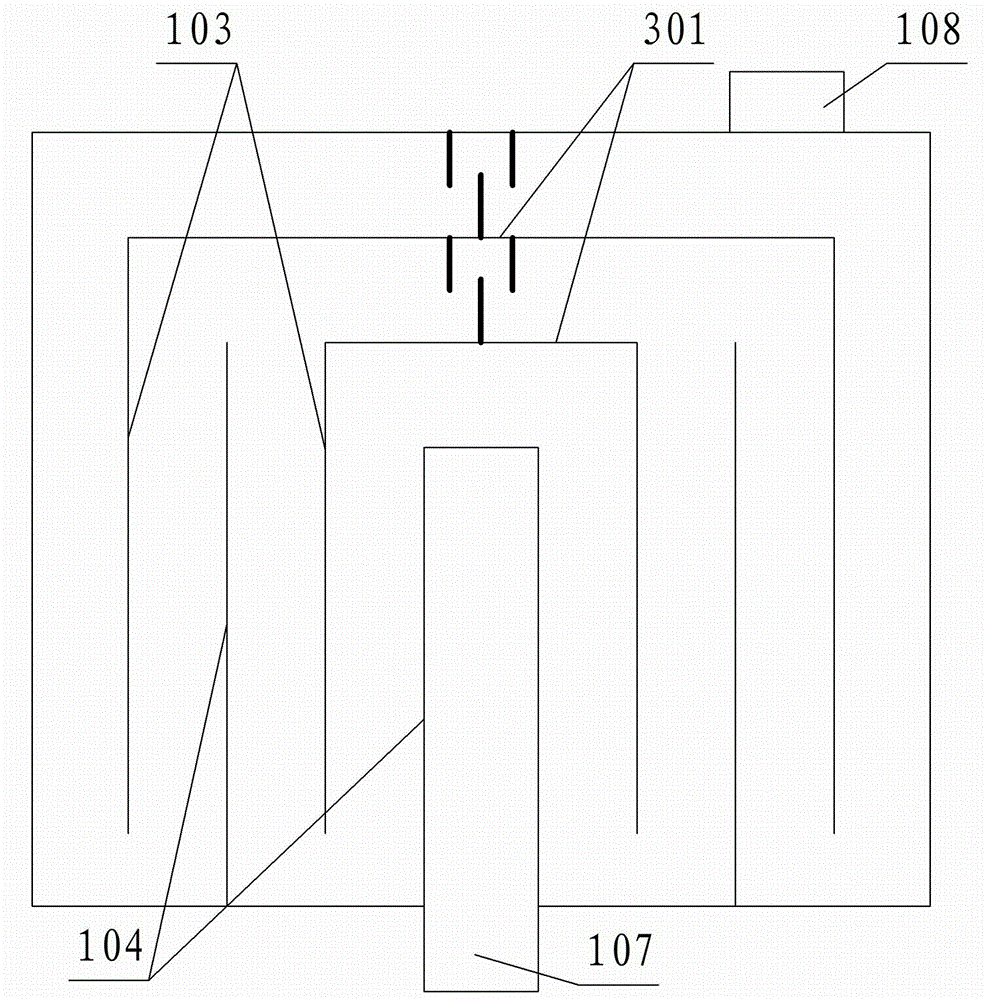

[0050] The axial-flow integrated drainage pump is powered by an external frequency conversion cabinet to control the frequency conversion start and operation of the water pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com