Probe special for performing eddy current testing on thimble tube of neutron flux instrument used by nuclear power plant

A technology for eddy current detection and finger bushing, which is applied in the field of special probes for eddy current detection of nuclear power plant neutron flux instrument finger bushings. Durable, safe and reliable in-service eddy current inspection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

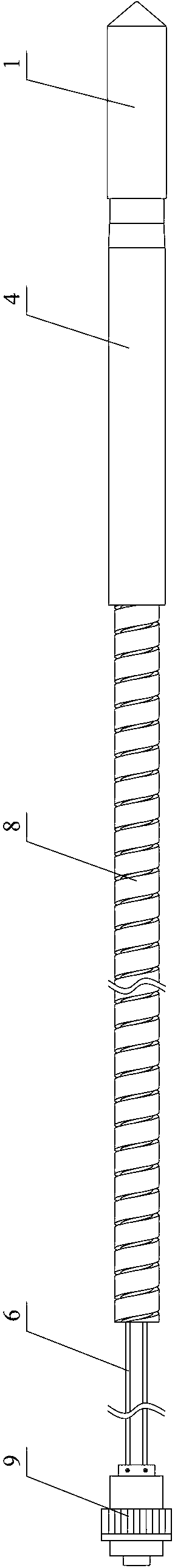

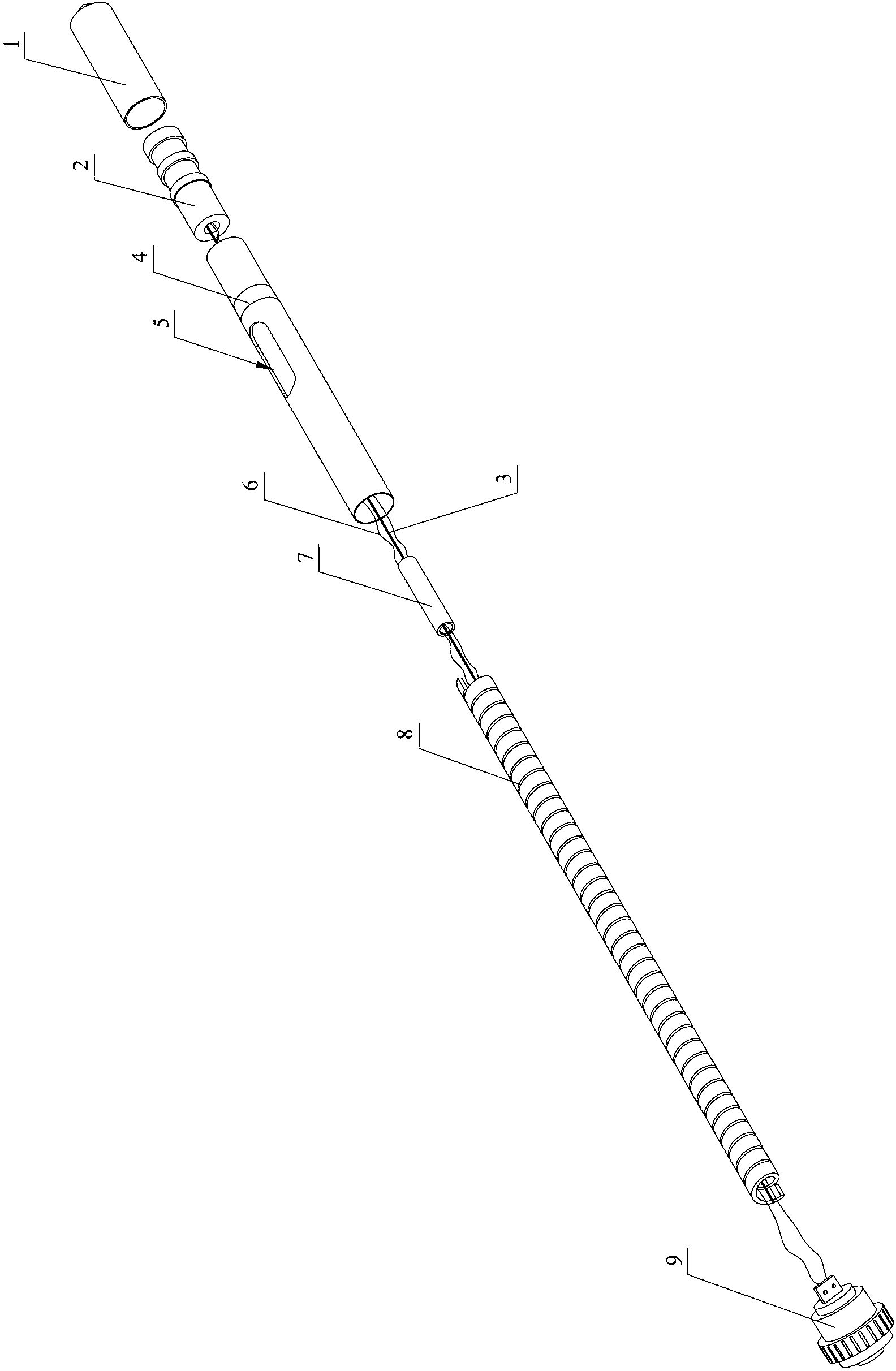

[0021] Embodiment one: see attached figure 1 And attached figure 2 shown.

[0022] The utility model relates to a special probe for eddy current testing of the bushing of a neutron flux meter used in a nuclear power plant, which is used for eddy current testing of the bushing of a neutron flux meter used in a nuclear power plant.

[0023] The special probe for eddy current detection includes a guide head 1, a copper sleeve 4 connected to the guide head 1 at one end, a coil bobbin 2 set in the copper sleeve 4, a coil wound on the coil bobbin 2, and the other end of the copper sleeve 4 Connected spring tube 8.

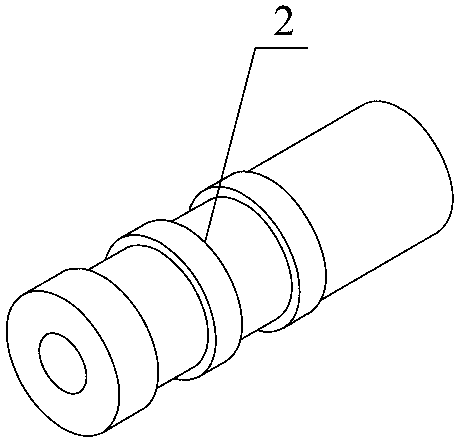

[0024] The guide head 1 is socketed on one end of the copper sleeve 4 . See attached image 3 to attach Figure 5 As shown, the bobbin 2 has a hollow interior, and grooves for winding coils are provided on its outer surface. Coils are precisely calculated and wound. First, determine the working frequency of the probe according to the material and wall thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com