An automatic gas channel switching system for an exhaust gas analyzer

A gas channel and exhaust gas analysis technology, applied in the direction of analysis materials, instruments, scientific instruments, etc., can solve the problems of heavy engine bench exhaust gas analyzer, difficult to move, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

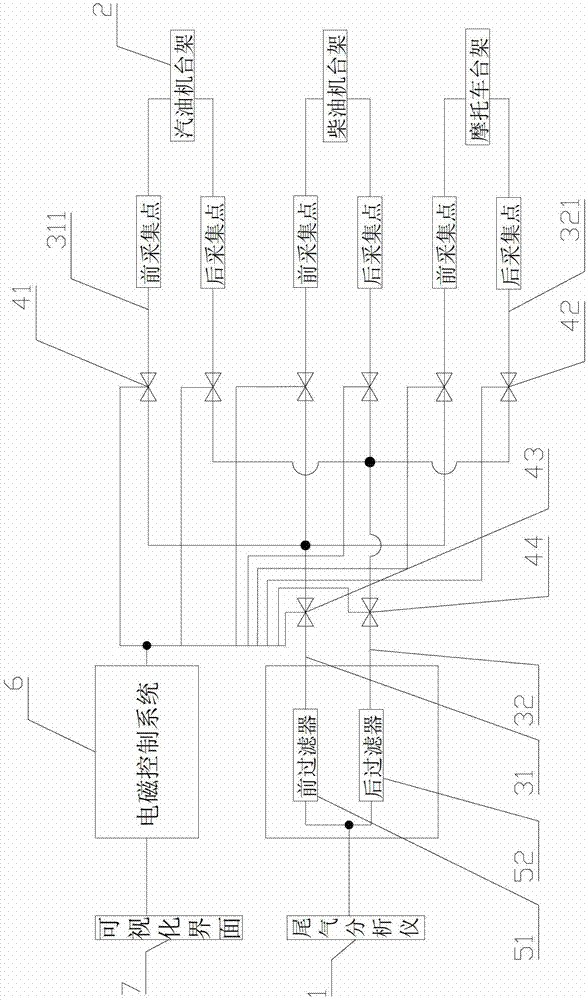

[0017] Such as figure 1 As shown, an exhaust gas analyzer gas channel automatic switching system includes an exhaust gas analyzer 1, an engine stand 2 and a gas channel connecting the exhaust gas analyzer and the engine stand, and several engine stands are respectively connected to a On the exhaust gas analyzer, each gas channel is provided with a channel switch 4 to control whether the gas in the gas channel passes through or not, and the gas channel is connected to the exhaust gas analyzer through a filter device, and also includes an electromagnetic control system 6. The electromagnetic control system is connected with the channel switch through the controller, and the electromagnetic control system is provided with a visualization interface 7, and the analysis command buttons of all engine stands are arranged on the visualization interface. The exhaust gas analyzer is equipped with a heating type total hydrocarbon analysis detector, an oxygen analysis detector and a heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com