Garlic splitting mechanical hand

A manipulator and clove-separating technology, which is applied in applications, food processing, food science, etc., can solve the problems of easy-to-damage garlic cloves, high labor intensity, and high energy consumption for garlic farmers, so as to improve time utilization efficiency and price Inexpensive and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

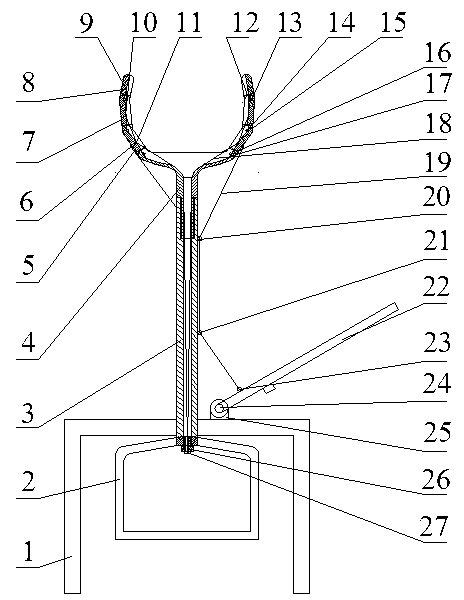

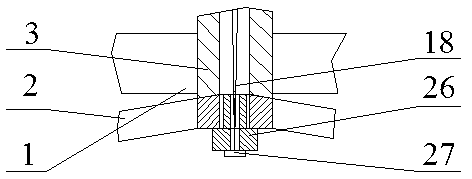

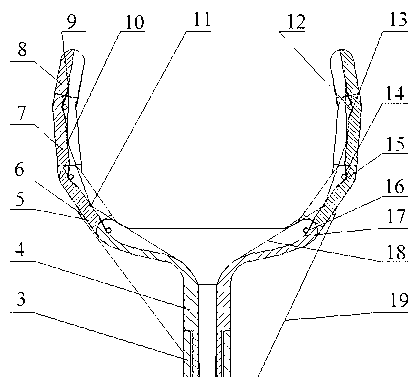

[0020] Embodiment 1: as Figure 1-5 As shown, a garlic splitting manipulator includes a base 1, a pedal 2, a support rod 3, a manipulator support seat 4, a lower knuckle 5, a middle knuckle 7, an upper knuckle 8, connecting steel wire I18, connecting steel wire II19, Depression bar 22, bolt with hole 26, stopper 27; Support bar 3 is installed on the base 1, pedal 2 is connected with support bar 3, bolt with hole 26 is installed on the pedal 2, and manipulator support seat 4 is installed on One end of the upper and lower knuckles 5 of the support rod 3 is connected with the manipulator support base 4, the other end is connected with the middle knuckle 7, the other end of the middle knuckle 7 is connected with the upper knuckle 8, a bracket 25 is installed on the base 1, and the pressure bar 22 passes through The pin 24 provided on it is installed on the bracket 25, and one end of the connecting steel wire I18 is connected with the lower knuckle 5, the middle knuckle 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com